Analysis of the Development Status and Trends of Unconventional Oil and Gas Cementing Materials (Part 2)

4. Nano Composite Materials for Well Cementing

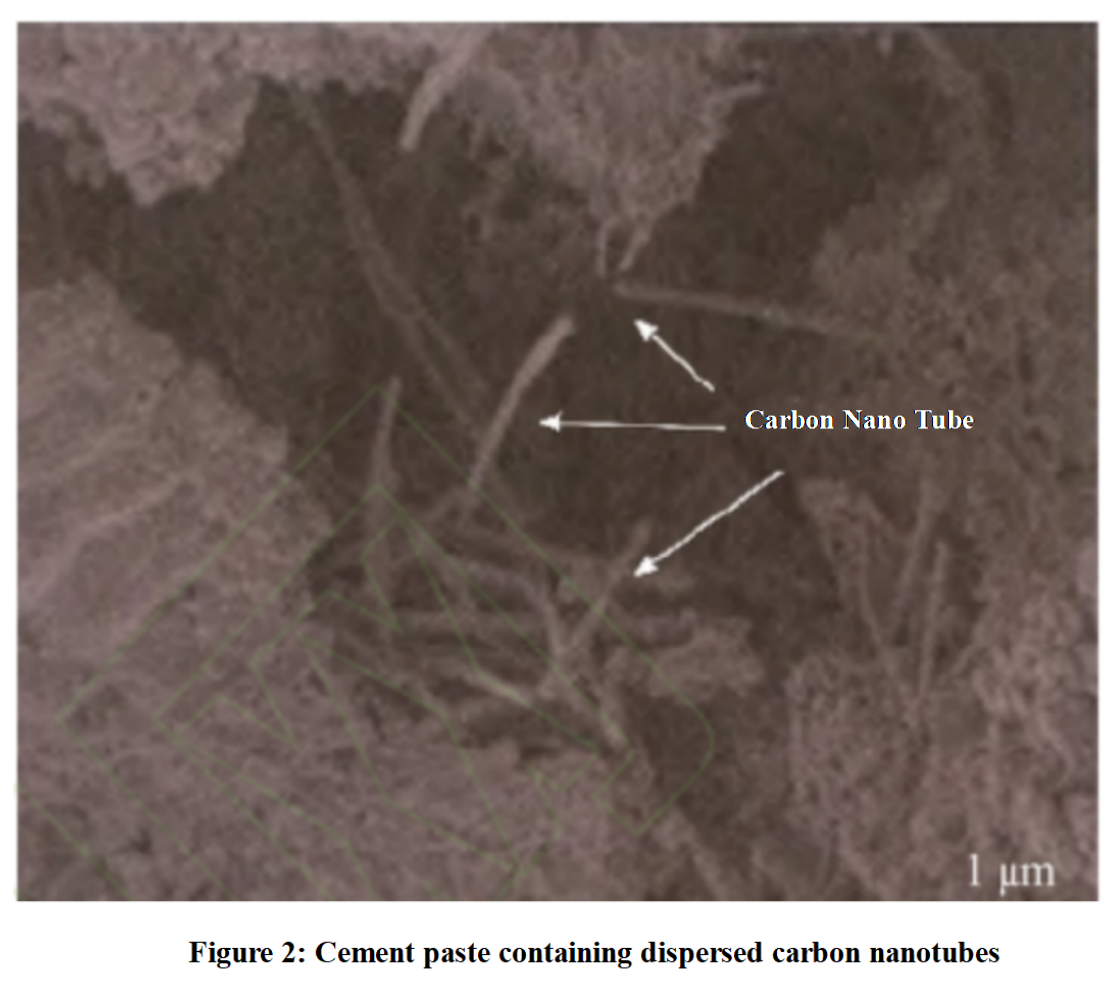

Nanomaterials mainly refer to particles with a size of 1-100nm, which can improve the density and interfacial bonding strength of cement during well cementing work. The micro mechanisms of nanomaterials enhancing toughness include pull-out, bridging, nano induced effects, and network filling effects, which can reduce the elastic modulus of cement paste and increase plastic deformation, thereby increasing the toughness of cement paste.

Li Yunjie et al. found that the synergistic effect of carbon nanotube CNTs and expansion agents forms a network structure inside the slurry through adsorption and entanglement, increasing the drag force of particle sedimentation and making the slurry less prone to delamination. Under high temperature and pressure conditions, the combination of CNTs and expansion agents has a better inhibitory effect on shrinkage, which can improve toughness and sealing ability. Jiang Guosheng et al. effectively shortened the waiting time of cement slurry, reduced water loss, improved the compressive strength of cement stone, improved reservoir sealing integrity, and prevented the strength decline of oil well cement at high temperatures by adding NS (nano silica) to the cement slurry, which helps to reduce the total cost of oil and gas field development. Sun et al. studied the effect of nanocellulose (CNF) on cementing cement through spectroscopic methods, combined with rheological modeling and strength analysis. CNFs have the characteristics of high strength, low cost, renewability, and safety. Compared with the original cementing cement, CNF reinforced cementing cement exhibits better mechanical and rheological properties. Ramana et al. used nano silica not only to enhance the development of early strength by shortening the hydration induction period, but also to improve the compressive strength of cement. Akshar uses nanoparticles to increase the compressive strength of cement, reduce the thickening time of cement, effectively reduce the porosity and permeability inside the cement, reduce the channels inside the cement, eliminate the risk of gas migration at high temperatures, and reduce fluid loss inside the cement. Vipulanandan modified smart cement with iron oxide nanoparticles to enhance its sensing performance, enabling monitoring of cement behavior at various stages of construction and throughout the lifespan of the well. After adding 1% nano iron oxide and curing for 1 and 28 days, the compressive strength of smart cement increased by 26% and 40%, and the elastic modulus increased by 29% and 28%.

5. Particulate Composite Materials for Well Cementing

The commonly used inorganic particles in well cementing particle materials include bentonite, silica fume, microspheres, and activated slag, while organic particles mainly include rubber powder, organic glass beads, etc. Due to its advantages such as good toughening effect, wide source of raw materials, and low production price, it has been widely used in cementing engineering. In recent years, research in this field has made rapid progress, especially in the design of cementing material ratios for deep shale oil and gas and coalbed methane, which has received widespread attention.

Feng Dapeng et al. pointed out that adding a suitable amount of rubber powder will fill the pores inside the cement stone and increase its density. At the same time, by using surfactants to hydrophilic treat the surface of elastic particles, the hydrophobic and agglomeration phenomena of elastic particles in cement slurry have been solved, making them have good dispersibility and no floating characteristics. Guo Guangfan et al. modified the surface hydrophilicity of waste tire rubber powder with different particle sizes, which significantly improved its impact resistance compared to unmodified rubber powder. Wu et al. prepared nano silica fume coated rubber composite particles using a particle composite system (PCS), and improved the toughness of oil well cement by filling with nano silica powder coated rubber particles. Huang Zhanying et al. utilized a new type of hollow spherical micro particle NHST-Q, which has the characteristics of a wide range of sources and low cost compared to conventional lightweight materials, and is suitable for low-pressure and easily leaking wells. Jia Chengqian et al. found that as the content of hollow microspheres increased, the thickening time of cement slurry was prolonged, and the strength decreased with the increase of content. Zuo Jingluan and others have selected hollow glass microspheres with no pores or capillary channels on the surface, which have the effect of reducing the density of cement slurry and the rheological properties of cement slurry, and have excellent pressure resistance and shear resistance.

Chen Jiebin et al. used 5% NaOH and 5% instant sodium silicate as alkaline activators to prepare metakaolin slag based polymers. The compressive strength can reach 28.68 MPa after curing under natural conditions for 3 days. Meng Jiajia and others used rich magnesium slag to prepare oil well cement stone. The early strength decreased with the increase of rich magnesium slag content, and the later strength gradually increased. Rukzon et al. used palm oil ash POA and fly ash FA as cement substitutes for volcanic ash materials in concrete, reducing the cost of cement, environmental impact, and the cost of waste ash treatment. The FA and POA blend cement slurry has relatively good strength and excellent resistance to chloride penetration. Marcos et al. found in their study of silica powder and metakaolin cement slurry systems that the maintenance of compressive strength is related to the formation of diatomaceous earth and calcium iron ore phases. Bu et al. pointed out that due to the volcanic ash reaction of metakaolin, the cement slurry replaced by metakaolin exhibits better corrosion resistance and is suitable for cementing operations in deep wells, acid rich wells, and geothermal wells.

6. Composite Cementing Materials

At present, the application of cementing materials mostly involves the composite use of various materials, achieving better toughening effects through synergistic effects. The elastic and ductile cement slurry system developed by Zhao Yuanwei et al. added elastic agent G404, with modified rubber powder as the main ingredient and short fibers as auxiliary materials, effectively improving the elastic modulus of cement paste. Han Fubin et al. added expansion agents and fiber materials to DHL latex cement slurry, which slightly reduced the fluidity of the cement slurry, slightly increased the density, and improved the compressive strength of the cement paste. Li Ming et al. used a mixture of whiskers and fibers, with whiskers being micrometer sized materials and fibers being millimeter sized materials. The synergistic effect was achieved at both scales. The compressive, flexural, and tensile strength of cement paste with added whiskers and fibers increased by approximately 24% to 50%, 20% to 60%, and 30% to 60%, respectively. Ma Xiaolong added 0.5mm fiber composite polymer lotion powder dried by spray into the cement slurry. The fiber plays a "skeleton" role in the cement paste. The polymer latex powder can improve its bonding performance and cohesion to reduce the elastic modulus of the cement paste, and the lattice expansion agent can reduce the shrinkage of the cement paste. Chen Jie et al. used solid latex powder and organic fibers compounded in a certain proportion to improve the sealing performance, high-temperature wear resistance, and high-temperature stability of cement slurry, and meet the requirements of cementing with large temperature differences. Peng Zhigang used the combined effect of rubber powder and fibers to transform the slag MTC solidified body, increasing its toughness, flexural strength, and impact toughness by more than 30%, enhancing the adhesion ability of cement stone, and increasing the bonding strength by more than 40%. Murtaza et al. mixed nanoclay with silica fume into oil well cement, and due to the smaller size and larger specific surface area of nanoclay, the compressive strength of cement samples was improved. Jingfeng has modified the surface of synthetic rubber powder by adding latex powder that can increase the internal cohesion of cement particles to the powder, producing a new toughening agent M91-S. Compared with conventional cement stone, toughened cement stone reduces the Young's modulus by 27.5%, increases flexural strength by more than 50%, increases fracture strength load by more than 50%, improves impact resistance by 23.7%, and increases tensile strength by 51.6%. Brothers et al. invented cement composites containing microspheres and carbon fibers, which can effectively improve the mechanical properties of cement. Microspheres can be obtained from industrial waste, greatly reducing production costs. Microspheres can reduce the density of the slurry, but excessive dosage can affect the tensile strength. Other additives need to be added to avoid affecting the cementing effect.

Ⅱ. The Demand for Cementing Materials in Unconventional Oil and Gas Development

The unconventional oil and gas development process has put forward different performance requirements for cementing quality. In the selection process of cementing materials, the main focus is on the problem of large-scale fracturing that cement stone needs to withstand in the development process of unconventional oil and gas wells. By improving the composition of cement slurry, the cement ring formed has higher toughness, and its integrity is ensured as much as possible when bearing loads. To a certain extent, the development of micro cracks and gas channeling phenomenon are avoided, reducing the impact on the recovery rate of unconventional oil and gas reservoirs and the service life of oil and gas wells. For different geological conditions of wells, there are different choices of cementing materials, and specific problems should be analyzed in detail. Choosing appropriate cementing materials is the key to solving cementing problems and improving cementing quality. The following will elaborate on the different requirements for cementing materials in the development process of unconventional oil and gas resources.

(1). Compressive Strength. The compressive strength of cement stone characterizes the ability to maintain the integrity of cement stone under compressive stress, which is currently the most important evaluation index for the application of cementing cement stone. Due to the use of large-scale fracturing in the development process of unconventional oil and gas, the large pressure difference caused by construction poses higher requirements for the compressive performance of cement stone. The research and development direction of cementing materials mainly focuses on how to improve the compressive strength of cement stone to ensure the service life of unconventional oil and gas wells. When testing the cementing effect of general cementing materials, the compressive strength of cement stone will be measured as a reference basis. Adding toughening materials such as fibers and particles to cement slurry can effectively improve the compressive strength of cement paste, and maintain the cement sheath from compressive failure under complex ground conditions.

(2). Anti-channeling Effect. Unconventional oil and gas resources such as shale gas and coalbed methane exist in the form of gas, and gas channeling prevention measures need to be taken during the extraction process to ensure the normal production of oil and gas wells. Polymer materials such as latex can often achieve good anti channeling and cementing effects in well cementing materials, forming dense polymer films that can effectively seal pores. Some nano cementing materials achieve good interface bonding effects through nano induced effects and mesh filling effects, while reducing gas escape under high temperature conditions.

(3). Rheological Properties. In the development process of cement slurry, it is necessary to improve its rheological properties in order to improve the displacement efficiency of cement slurry and significantly enhance cementing efficiency. Improve the static and dynamic shear forces of cement slurry to be higher than that of drilling fluid, in order to improve the efficiency of replacing drilling fluid with cement slurry under turbulent flow conditions. By adjusting the dosage of cementing materials, the effect of adjustable thickening time can be achieved, so that when the cement slurry reaches the designated position, it can be fully replaced and form a uniform and dense cement ring, ensuring the quality of cementing.

(4). Crack Resistance. Most cement rings break due to the initiation and development of cracks, while cementing materials such as fiber materials prevent further crack propagation by bridging the cracks and reducing stress concentration at the crack tip. The crack resistance is related to the tensile strength. The stronger the ability of cement stone to resist expansion and tension, the less likely it is for cracks to occur and expand. Adding materials such as whiskers to cement reduces the elastic modulus and increases the tensile strength. Cracks in cement stone can also lead to gas channeling, and selecting denser cementing materials can achieve the crack resistance effect of cement.

(5). Impact Toughness. Improving the impact toughness of cement sheath can effectively improve the quality of cementing. Due to the fact that oil and gas wells are under alternating load conditions, conventional cement exhibits brittle failure. Therefore, in order to make the cement stone withstand more impact energy, the addition of cementing materials can reduce the Young's modulus of cement, improve the toughness of the cement stone, sacrifice some acceptable strength, and have better impact resistance. Adding fiber and particle cementing materials to cement slurry can achieve excellent results in reducing brittleness and toughening.

(6). Ability to Resist High-temperature Heat Damage. In the development process of some geothermal wells and deep unconventional oil and gas resources, it is required that the high-temperature resistance of cement slurry can be achieved to complete cementing work under large temperature difference conditions. By modifying unconventional cementing materials for oil and gas wells, the cement slurry can still maintain good performance in high-temperature environments, achieving stable recovery of oil and gas wells. The thickening time of cement slurry and the strength of cement stone formed are constrained by high temperature conditions. Therefore, selecting high-temperature resistant cementing materials such as nanomaterials is an effective way to solve such well conditions.

(7). Corrosion Resistance. Some underground reservoir environments contain acidic corrosive gases such as hydrogen sulfide, which react with the effective components of cement, leading to a decrease in cement strength. The main way to solve such problems is to optimize cementing materials such as fly ash and siliceous materials, reduce the content of calcium hydroxide in cement paste, and thus alleviate the intensification of corrosion. It is also possible to reduce porosity and improve cement density by adding corrosion-resistant polymers and other materials, prevent gas infiltration, slow down corrosion reactions, and achieve the goal of improving cementing quality.

(8). Self-healing. Adding a certain amount of self repairing agent to cement slurry can greatly prolong the service life of unconventional oil and gas wells, and achieve self repairing effects through mechanisms such as crystallization precipitation and permeation precipitation. The addition of self-healing materials can significantly improve the sealing effect, reduce permeability, and the crystals generated by the reaction can fill the cracks and pores that appear during the cement solidification process to a certain extent, thereby improving the strength and quality of cement placed for a certain period of time.

(9). Intelligent Cementing Materials. Intelligent research on cementing materials, such as signal transmission and intelligent diagnosis of wellbore service health, optimizes the sensing performance of cementing materials for real-time detection of cementing conditions, judges downhole conditions based on the electrical signal returned by cementing cement, and adjusts cementing operations more accurately from factors such as thickening and dispersion.

Ⅲ. Outlook on the Development Trends of Unconventional Oil and Gas Well Cementing Materials

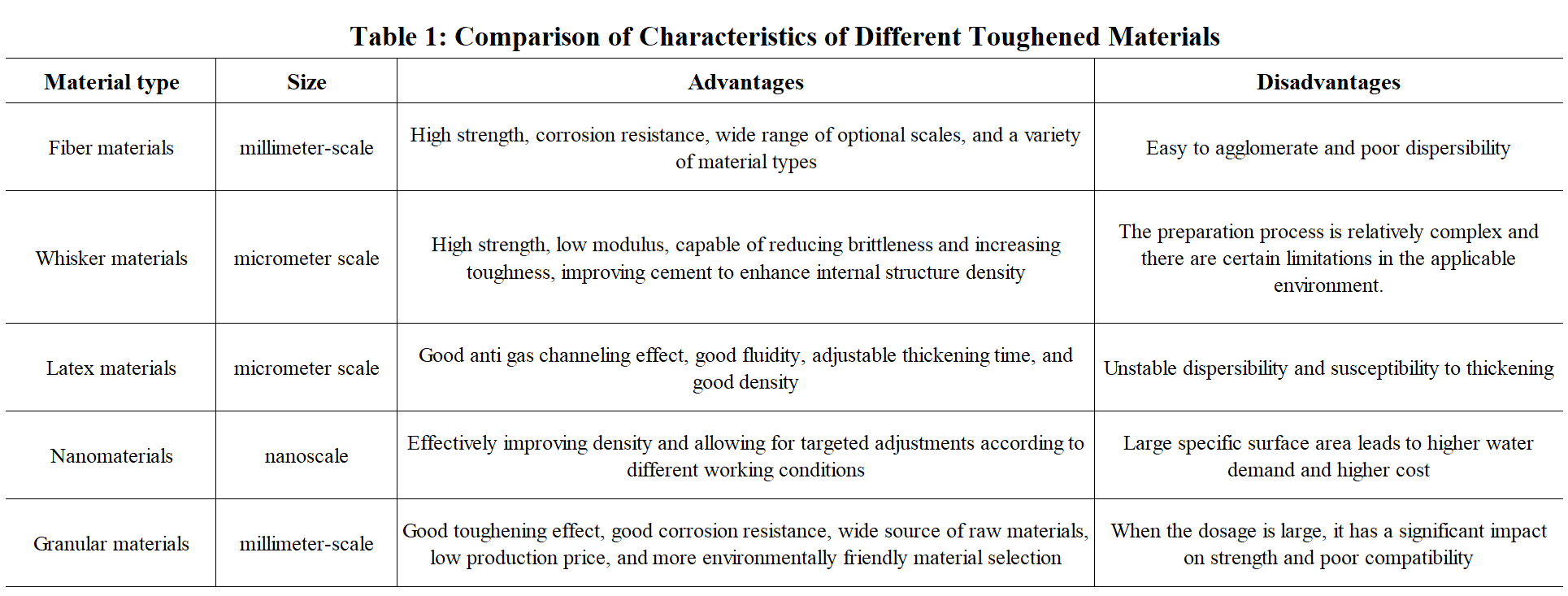

After analyzing and summarizing the characteristics and research status of various unconventional oil and gas well cementing materials such as fibers, whiskers, polymer, nanoparticles, and particles, it is not difficult to find that they all have certain advantages and disadvantages. Fiber materials can improve the mechanical properties of cement stone, play an important role in maintaining the integrity of the cement ring, and are inexpensive. However, their disadvantage is that fibers are prone to agglomeration, and suitable dispersants need to be selected to improve the toughening effect. Whisker materials can effectively improve the strength of cement stone and reduce the elastic modulus. The research direction of whisker materials should focus on the surface treatment of whisker materials, and improve the preparation method of whiskers to obtain whisker materials with better toughening effect and higher cost-effectiveness. The problem of dispersion instability of latex materials in oil well cement slurry requires the development of appropriate stabilizers to solve the phenomenon of material aggregation and thickening. There are various types of nanomaterials that can be used to enhance the toughness of cement at the nanoscale, and targeted improvements can be made according to different needs. However, nanomaterials have the problem of high cost, and suitable dispersion stabilizers need to be developed to better enhance the toughening effect. In the research of particulate materials, the focus should be on the surface modification technology of organic particulate materials to ensure good compatibility between particles and cement.

Based on the different requirements of unconventional oil and gas wells for cementing materials under different conditions, including compressive strength, anti channeling effect, rheological properties, crack resistance, impact toughness, resistance to high-temperature thermal damage, corrosion resistance, self-healing ability, intelligence, etc., it is speculated that the future development direction of cementing materials will focus on mixing and using two or more types of materials, taking into account the advantages of various cementing materials, Fully leverage the synergistic effect of various materials, complete the reinforcement of cement stone at different scales, and improve the quality of cementing.

To achieve more efficient development of unconventional oil and gas resources, it is necessary to develop cementing materials with higher cost-effectiveness, optimize the real-time monitoring technology of cement status during the cementing process, accurately adjust the composition of cementing materials, and ensure the smooth progress of cementing work. Integrating cementing materials with intelligent technology provides strong support for the scale and efficiency development of unconventional oil and gas resources.