The Influence of Modified Basalt Fiber on the Mechanical Properties of Oil Well Cement (Part 3)

2.2 Dispersion Properties of Basalt Fibers

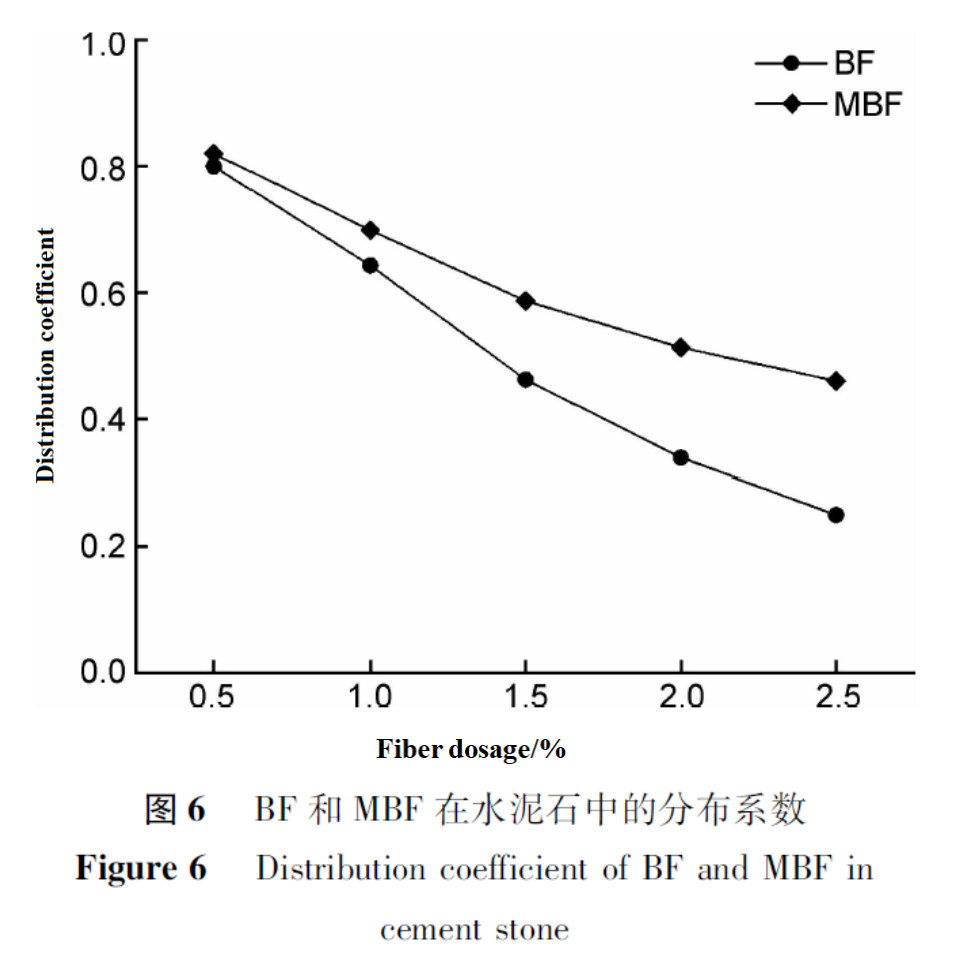

The distribution of basalt fibers in cement paste was statistically analyzed using image processing software Image Pro Plus, and the fiber distribution coefficient β was calculated for each group of samples. The results are shown in Figure 6.It is known that the closer the value of β is to 1, the better the dispersion. As the fiber dosage increases, the fiber distribution coefficients of BF and MBF gradually decrease.However, compared to BF, the fiber distribution coefficient of MBF shows a slower downward trend. When the fiber content is 0.5% (mass fraction), the fiber distribution coefficients of BF and MBF are 0.80 and 0.82, respectively; When the fiber addition is 2.5%, the fiber distribution coefficients of BF and MBF are 0.25 and 0.46, respectively. Therefore, the fiber distribution coefficient of MBF has increased by 84% compared to BF.Based on the above data, it can be seen that modifying basalt fibers can significantly improve their dispersibility in cement.

2.3 Mechanical Properties of Basalt Fiber Cement Stone

(1). Compressive and Flexural Strength of Cement Stone

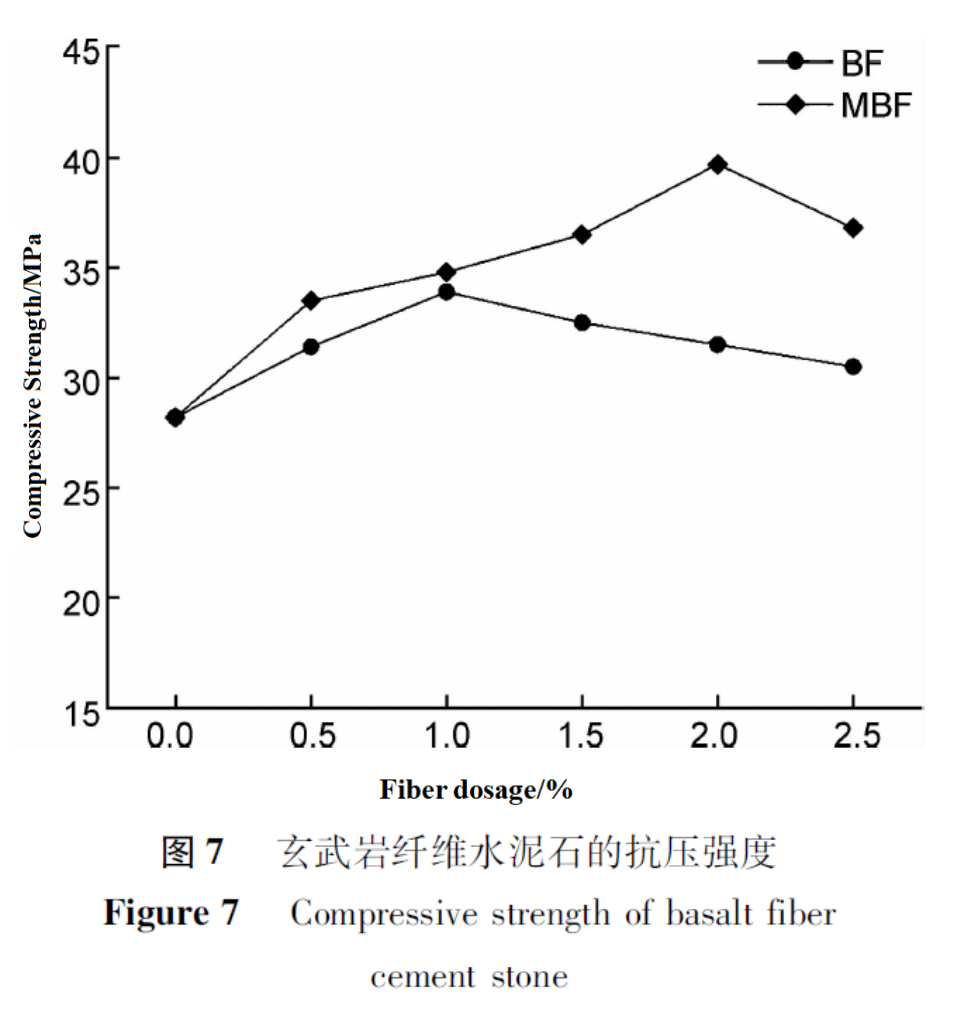

Figure 7 shows the compressive strength of basalt fiber cement paste with different dosages. The results indicate that with the increase of fiber dosage, the strength of cement paste first increases and then decreases, because the reinforcing effect of fibers is based on their good dispersion in the cement matrix.When the fiber dosage is appropriate, its dispersion effect in cement slurry is good, and more fibers participate in the strength development of cement stone; When the dosage exceeds a certain amount, the dispersion effect of fibers deteriorates, which is detrimental to the strength development of cement paste.It can be seen that MBF can achieve a good dispersion addition of 2%, while BF can achieve a good dispersion addition of 1%, indicating that fiber surface modification contributes to the improvement of fiber dispersion performance. In addition, under the same dosage, the strength of MBF cement stone is higher than that of BF cement stone. When the dosage is 2%, the compressive strength of MBF cement stone is the highest, at 39.5Mpa, while that of BF cement stone is 31.2Mpa. MBF cement stone has an increase of 26.6% compared to BF cement stone and an increase of 40.1% compared to cement stone with 0% fiber addition.

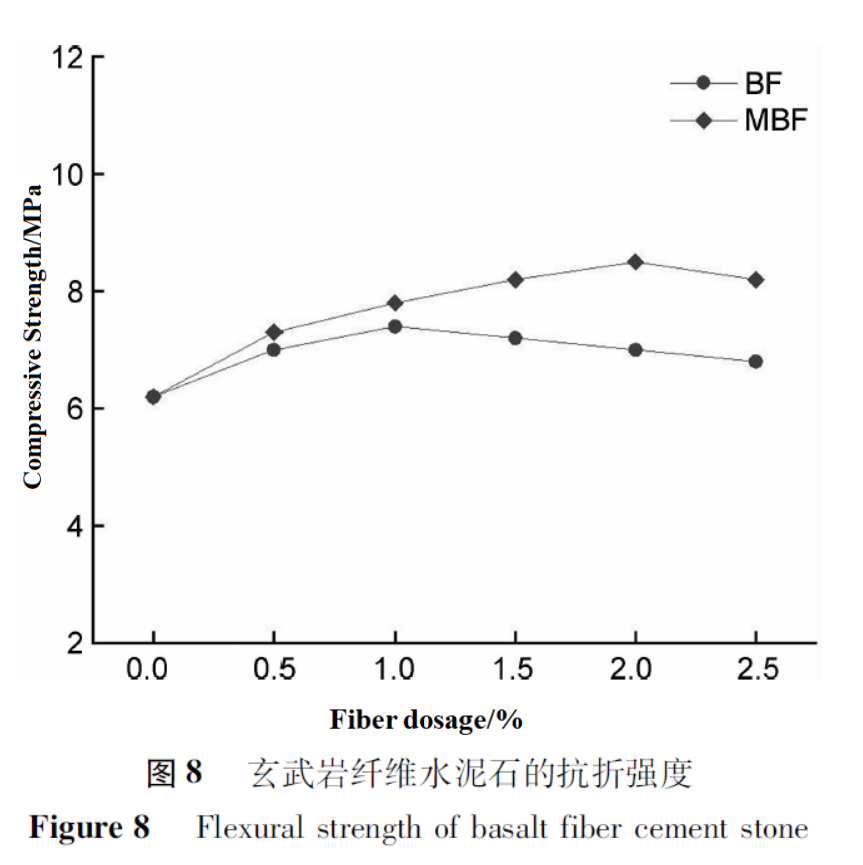

Figure 8 shows the effect of adding basalt fiber on the flexural strength of cement paste. From Figure 8, it can be seen that the influence trend of BF and MBF on the flexural strength of cement paste is similar to that of compressive strength, and there is also a trend of first increasing and then decreasing between flexural strength and fiber addition.Under the same dosage, MBF has higher flexural strength compared to BF cement stone. When the dosage is 2%, the flexural strength of MBF cement stone is the highest, at 8.5Mpa, and the flexural strength of BF cement stone is 7.0Mpa. MBF cement stone has an increase of 21.4% compared to BF cement stone, and an increase of 37.1% compared to cement stone with 0% fiber dosage.Overall analysis shows that MBF has better dispersibility than BF, with a higher achievable dosage for achieving good dispersion in cement, and a greater improvement in the mechanical properties of cement stone.

(2). Bond Strength Between Fibers and Cement Stone

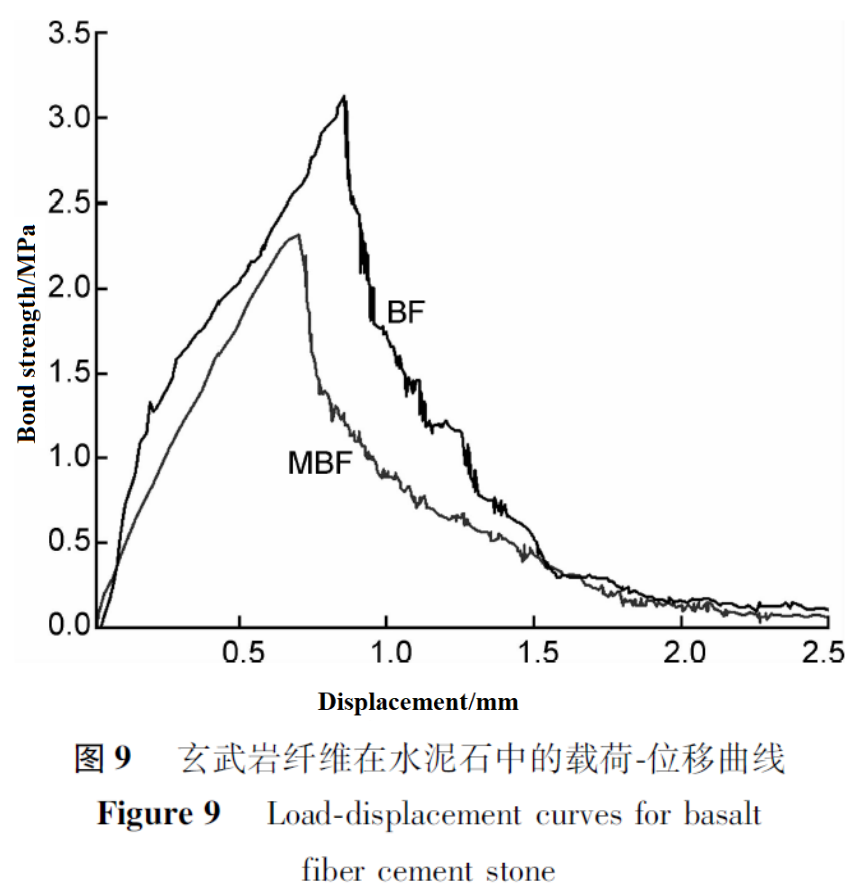

The load displacement curves of BF and MBF in cement stone were obtained through single wire pull-out test, and the results are shown in Figure 9. Under the action of load, basalt fibers undergo elastic deformation, and the displacement shows a linear increasing trend with the load.When the load reaches its maximum value, the fibers detach from the cement matrix, causing the load to slip rapidly, and then the fibers gradually slide out of the cement matrix. Comparing the load displacement curves of BF and MBF, it can be seen that the debonding load of MBF is greater than that of BF.The maximum bonding strength between BF and cement stone is 2.31 MPa, while the maximum bonding strength between MBF and cement stone is 3.13 MPa, which is 35.5% higher than that of unmodified basalt fiber. This indicates that the modification of basalt fiber increases the activity and roughness of the fiber interface, improves the bonding performance of basalt fiber, and is conducive to further improving the mechanical properties of cement stone.

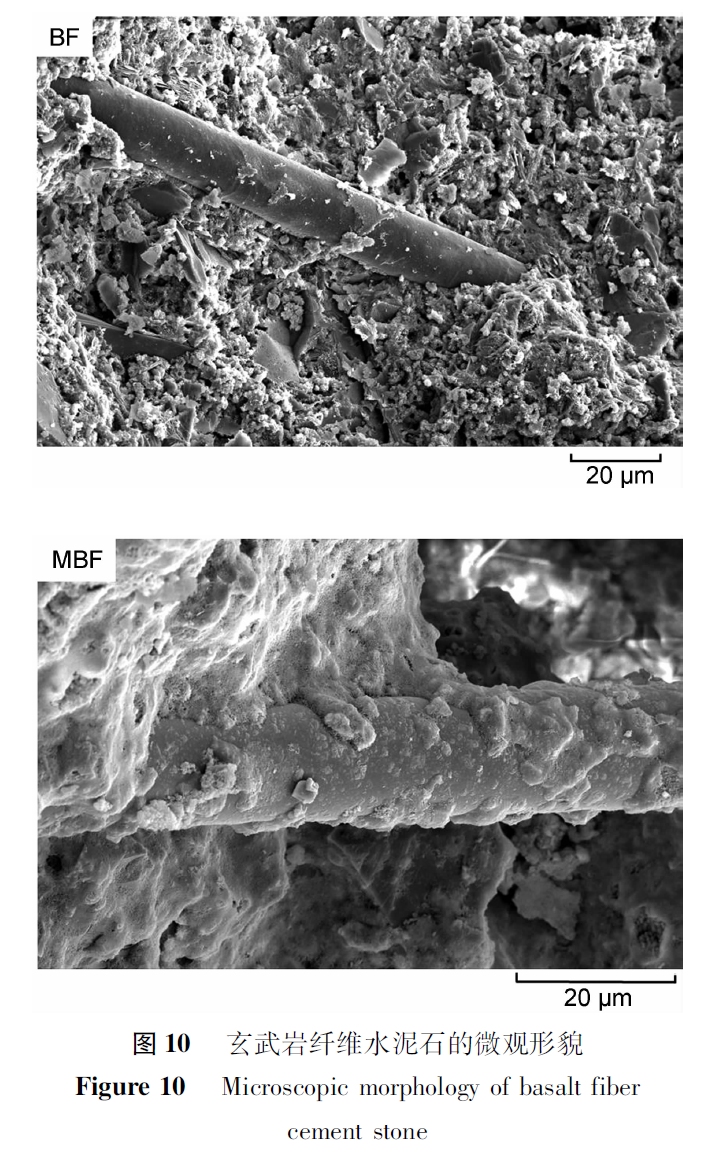

2.4 Microscopic Morphology Analysis of Basalt Fiber Cement Stone

The microstructure of basalt fibers in cement paste before and after modification is shown in Figure 10. Comparing BF and MBF, it can be seen that the surface of BF is very smooth and has a lower degree of fit with the cement matrix. The surface of MBF is rough, and it fits more tightly with the cement matrix, which is conducive to reducing the porosity in the cement stone, making the structure of the cement stone relatively denser, and enhancing the mechanical properties of the cement stone.

3. Conclusions

This study used a coating method to modify the surface of BF, improving the dispersion of fibers in cement and enhancing the mechanical properties of cement stone. A hydrophilic cationic coating agent was prepared using poly (methyl methacrylate), coupling agent KH-570, and hexadecyltrimethylammonium chloride, and successfully coated onto the surface of BF.The results indicate that: (1). The surface modification of BF has improved the dispersibility of basalt fibers in cement by introducing hydrophilic groups and N+(CH3) 3 groups.The dispersibility of BF in cement paste was evaluated using image method, and the distribution coefficient of MBF increased by 84% compared to before modification, indicating better dispersibility;(2). Due to the improved dispersibility of MBF in cement, it has a higher achievable dosage for achieving good dispersion in cement, allowing more fibers to participate in the dispersion of internal stress in cement. At the same time, the surface roughness of modified fibers increases, and they bind more tightly with cement hydration products, thereby enhancing the mechanical properties of cement paste.