Synthesis and mechanism of fluid loss additive for high temperature resistant drilling fluid (Part 3)

2.4 Research on the Mechanism of High Temperature Resistant Drilling Fluid Loss Additive

2.4.1 Micromorphology of filter cake

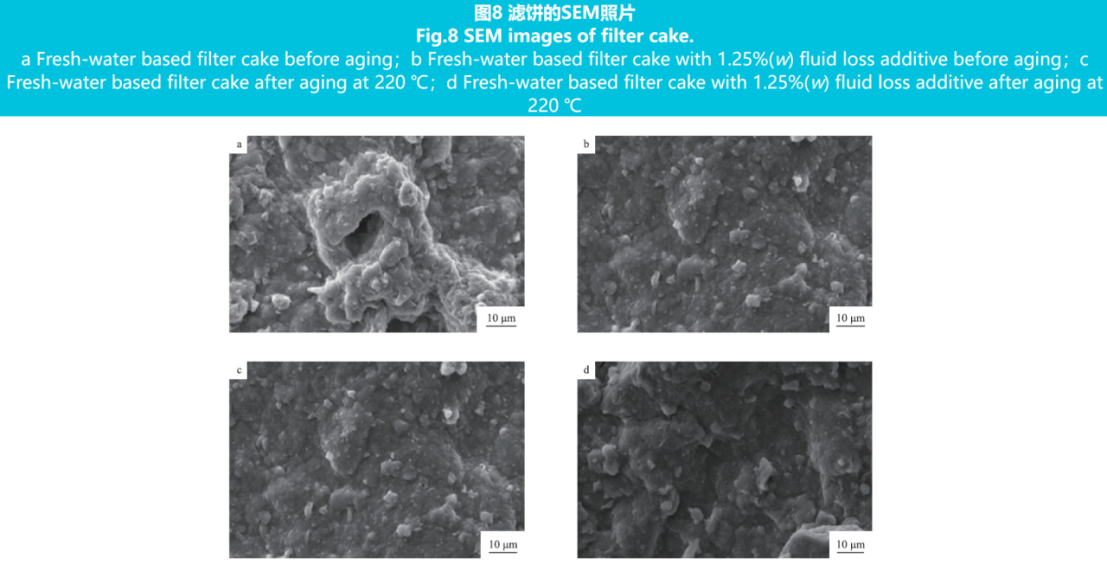

The microstructure of the filter cake helps to reveal the mechanism of action of the fluid loss agent. The prepared fresh water base slurry and the base slurry with a 1.25% (w) water loss agent dosage were subjected to API filtration loss measurement before and after aging at 220℃. After measuring the API filtration loss for 30 minutes, the filter cake was removed, and the loose clay particles suspended on the surface were washed away with deionized water. After natural drying, a small piece of gold was cut off for spraying treatment. Figure 8 shows an SEM photo of the filter cake.

From Figure 8a, it can be seen that the surface of the drilling fluid based mud filter cake is uneven and overall loose and porous, with microcracks and large particle pores. The microporous structure formed by the aggregation and stacking of bentonite particles provides an invasion channel for fluid to enter the formation, leading to an increase in filtration loss.

From Figure 8b, it can be seen that after adding polymer fluid loss additive before aging, the filter cake of the drilling fluid becomes smooth, without obvious large particles of clay and pores, and the particles are tightly packed.

From Figure 8c, it can be seen that after the aging of the freshwater base slurry, obvious cracks appear, with obvious large clay particles on the surface and porosity between the particles.

From Figure 8d, it can be seen that the surface cracks and pores of the filter cake with the addition of a fluid loss additive disappear, and the surface is relatively smooth without obvious large particle clay aggregation, resulting in a more compact filter cake. This is mainly because the filtrate reducer is mainly composed of carbon chains, with numerous sulfonic acid groups and polyoxyethylene ether groups on the side chains. The sulfonic acid group has a high charge density and strong hydration ability; The adsorption of polyoxyethylene ether groups and clay forms a network structure, which is wrapped around clay particles. The branched structure of the fluid loss agent prevents aggregation between particles, forming a dense structure and reducing mud water loss.

2.4.2 Element distribution on the surface of filter cake

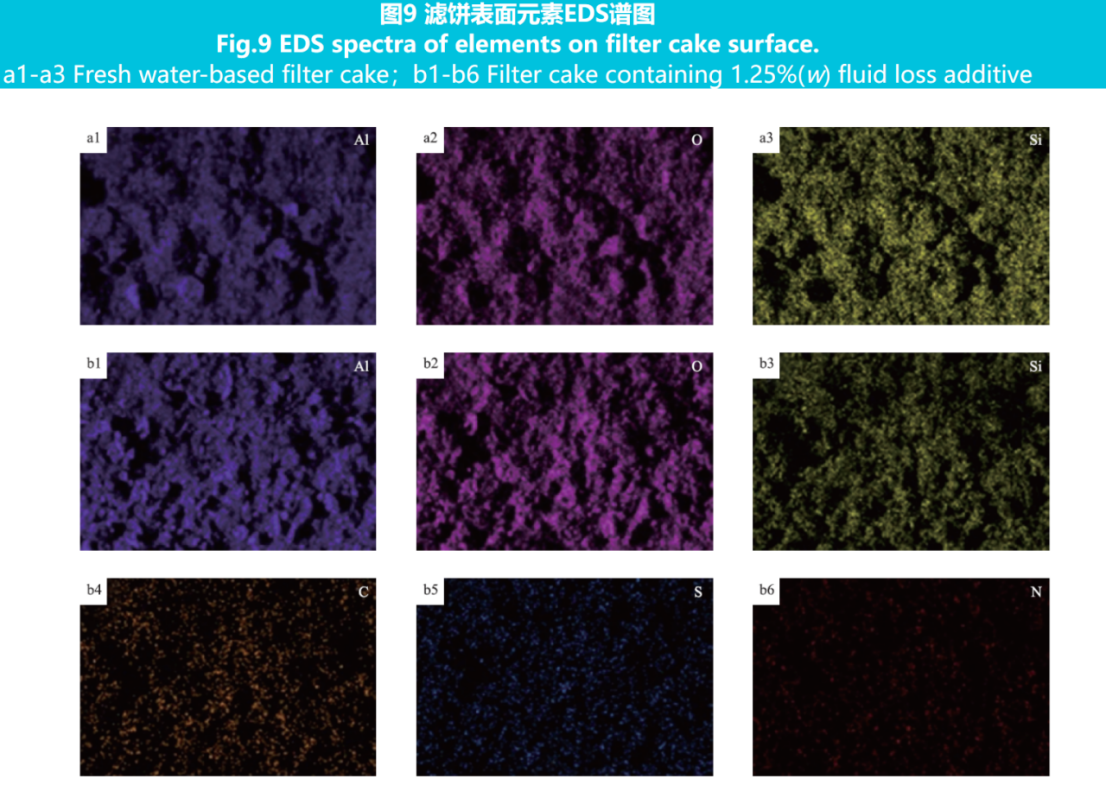

The crystal structure of bentonite is composed of two SiO2 oxygen sheets sandwiched by an aluminum oxide sheet, which is called a 2:1 type clay mineral. Oxygen atoms are distributed above and below the crystalline layer of bentonite, and the interlayer is connected by weak intermolecular forces. Therefore, the molecules of the fluid loss agent are easy to enter the interlayer of the clay, causing lattice expansion and enhancing colloidal activity. After aging at 220 ℃, the fresh water based slurry filter cake and the filtrate reducer based slurry filter cake were washed off with deionized water to remove suspended clay particles on the surface. After drying a small piece, the surface elements of the filter cake were characterized by EDS, and the interaction mechanism between the filtrate reducer and bentonite was further studied. Figure 9 shows the EDS spectrum of surface elements on the filter cake.

From Figures 9a1 to a3, it can be seen that the surface elements of the slurry filter cake are mainly aluminum, oxygen, and silicon, which are the main components of bentonite.

From Figures 9b1 to b6, it can be seen that in addition to aluminum, oxygen, and silicon elements, there are also characteristic elements (carbon, sulfur, and nitrogen) of the filtrate reducer molecule on the surface of the filtrate reducer cake, indicating the successful adsorption of the filtrate reducer on the bentonite surface.

2.4.3 Adsorption of fluid loss agents on clay like surfaces

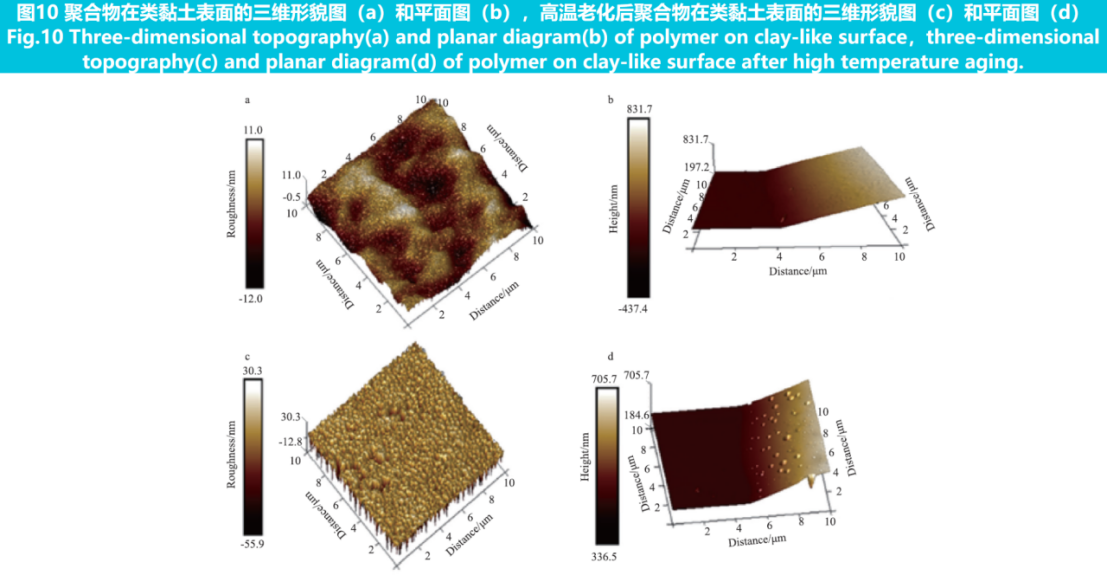

The interaction between the fluid loss agent and clay directly affects the performance of drilling fluid, and the fluid loss agent must be adsorbed on the surface of clay to maintain clay dispersion. The main component of clay, montmorillonite, has the same crystal structure as mica flakes, so mica flakes were selected as the sample carrier. Take 1.25% (w) polymer solution and the polymer solution aged at 220℃, add them dropwise onto mica sheets, dry them, and observe the adsorption morphology of the fluid loss agent using AFM. The results are shown in Figure 10.

From Figures 10a and b, it can be seen that polymers stack and connect with each other on the clay like surface to form a three-dimensional grid, forming a layer of polymer film with a thickness of 831.7 nm and a roughness of only 11.0 nm. It indicates that the polymer surface is relatively smooth before aging, and the polymer adsorbs evenly on the surface of clay like soil. From Figure 10c and d, it can be seen that, unlike the unaged three-dimensional morphology, after high-temperature aging at 220℃, when molecules adsorb on the surface of the clay like soil, the longitudinal roughness of the membrane increases to 30.3 nm due to molecular condensation, and the roughness of the membrane is greater. However, there is still a layer of adsorption membrane on the carrier, and the thickness of the membrane decreases to 705.7 nm. This is because the polyoxyethylene ether and amide groups on the molecular side chains form hydrogen bonds with the surface hydroxyl groups of the clay like soil, forming a layered polymer film through adsorption; After high-temperature aging, the polymer exhibits stacking due to thermal degradation of the main chain, changes in molecular structure, and molecular aggregation. However, the sulfonic acid groups on the benzene ring inhibit hydrolysis, and hydration still exists. Nitrogen ions with hydrophobic long chains can still adsorb water molecules to form a hydration film at high temperatures, resulting in stable adsorption on the surface of clay like soil, Therefore, polymers still have filtration reduction properties at high temperatures.

3. Conclusion

1). A quaternary copolymer was synthesized using AM, APEG-1000, SSS, and DMAAC-18 as monomers through free radical aqueous solution polymerization. The optimal synthesis conditions were as follows: monomer ratio n(AM):n(APEG-1000):n(SSS):n(DMAAC-18)=110:3:10:1, reaction temperature 60℃, reaction time 4 hours, total monomer content 30% (w), initiator dosage 0.4% (w), reaction pH=8.

2). The optimal dosage of fluid loss agent in water-based drilling fluid is 1.25% (w), with an API filtration rate of 7.3 mL and an API filtration rate of 13.2 mL after aging at 220℃; In the polysulfonic acid drilling fluid system, the HTHP filtration loss after aging at 220 ℃ was only 13.6 mL when mixed with the commonly used sulfonated filtrate reducer SMP in the oil field, indicating good compatibility and resistance of the filtrate reducer.

3). The filter cake was characterized by SEM and EDS, and the polymer solution was characterized by AFM. The characterization results showed that the filtrate reducer had a strong adsorption effect; By using AFM, it can be visually observed that the polymer solution forms a layer of polymer film on clay like soil, effectively reducing filtration loss.