Synthesis and Performance Evaluation of Zwitterionic Polycarboxylate Dispersants for Cementing Slurry(Part 1)

Abstract

The production and use of existing polymer dispersants are limited due to technical and environmental issues.Polycarboxylic acid (PCE) high-performance water reducer is widely used in the concrete industry due to its green and environmentally friendly properties and excellent dispersibility. However, the conventional application of PCE in cement slurry for well cementing has strong retarding problems.Conventional anionic polycarboxylate (CPC) and zwitterionic polycarboxylate (DPC) dispersants were synthesized using methallyl polyethylene glycol ether, acrylic acid, and methacryloyloxyethyltrimethylammonium chloride as raw materials. Their structures were characterized, and the effects and mechanisms of CPC and DPC on the flowability, rheological properties, thickening time, and compressive strength of cement slurry were studied.The results indicate that both CPC and DPC have good dispersibility, but DPC far exceeds CPC in thickening time and compressive strength performance.CPC has a strong retarding effect, leading to a significant extension of thickening time and a decrease in early strength of cement paste. DPC synthesized by introducing quaternary ammonium cations has a weak retarding effect and has little effect on thickening time, which is beneficial for improving the early strength of cement paste.

The "long horizontal well+super fracturing" technology is one of the most influential oil and gas exploration and development technologies in the past 10 years, widely used in tight oil and gas extraction.Technical difficulties such as high cement slurry construction friction and abnormally high pump pressure have arisen during the ultra long horizontal cementing construction, seriously affecting the safe construction and cementing quality of tight oil and gas long open hole horizontal sections.Dispersant (known as water reducing agent in the construction industry) is one of the three major additives for oil well cement, used to prevent cement particle agglomeration, reduce the viscosity of cement slurry, decrease pumping pressure, and achieve low-speed turbulent injection of cement.At present, sulfonated acetone formaldehyde condensate (SAF) is the most commonly used dispersant for oil well cement. The product appearance is a reddish brown powder, which disperses cement particles through electrostatic repulsion. However, due to its molecular structure limitations, the dispersion efficiency is not high, and it is used in large quantities. At the same time, its production process involves harmful substances such as formaldehyde, which does not meet the environmental requirements of "de sulfonation".

Polycarboxylate (PCE) is usually a comb shaped polymer composed of main chain anionic anchoring groups and non-ionic hydrophilic long side chains. It has a unique spatial hindrance dispersion mechanism and is the most widely used water reducer in construction cement. The product is environmentally friendly and has excellent dispersion performance, making it the development direction of high-performance cement dispersants.Since the invention of the first generation PCE (JP57118058) in Japan in 1981, PCE has had a very high market share in the concrete water reducing agent market, and can be directly applied in oil well cement.ZHAI et al. found that PCE water reducer has better dispersibility than SAF in medium and low temperature oil well cement slurry, but has strong retarding side effects and low early strength.Yu Bin et al. used a combination of polycarboxylate and sulfonated aldehyde ketone condensates to solve the problems of low temperature retardation of polycarboxylate dispersants and adverse effects on the thickening curve of cement slurry at high temperatures.Zhou Shiming et al. used a combination of polycarboxylate and alcohol amine accelerators to significantly reduce the viscosity of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) cement slurry systems and solve the problem of polycarboxylate dispersants slowing down.Feng Qian et al. introduced AMPS to synthesize sulfonated polycarboxylates, and the results showed that moderate addition of sulfonic acid monomers could reduce the retarding effect of conventional polycarboxylates.In summary, in order to solve the problem of strong side effects of PCE retarding, previous researchers have mostly used physical compounding early strength agents or partially replaced carboxylic acid monomers with sulfonic acid monomers to synthesize PCE. However, physical compounding cannot solve the problem from the source, and the use of sulfonic acid monomers does not conform to the development trend of "de sulfonation" in the oil and gas extraction industry.

The adsorption performance of various anchoring groups in polymers on cement particles is ranked as follows: phosphate group>carboxylic acid group>sulfonic acid group>quaternary ammonium cation.The retarding effect brought by anchoring groups is negatively correlated with adsorption performance. Phosphate groups have the strongest retarding effect, while quaternary ammonium cations have almost no retarding effect. The reason is that phosphate groups and carboxylic acid groups have strong calcium ion chelation, which prolongs the time required for the calcium ion concentration to reach supersaturation during the cement hydration induction period. Quaternary ammonium cations do not chelate with calcium ions, so they will not prolong the cement hydration time.Therefore, based on the surface electrical distribution of cement particles and the adsorption and dispersion mechanism of polycarboxylates, this paper introduces cationic monomers moderately into the PCE molecular structure as supplementary adsorption monomers to design and synthesize environmentally friendly zwitterionic polycarboxylate dispersants. This reduces the proportion of carboxylic acids in the PCE molecular structure while maintaining the original adsorption and dispersion effect, achieving high dispersion performance and low retardance, and promoting the upgrading and replacement of oil well cement dispersants.

1. Experimental Section

1.1 Instruments and Reagents

WQF-520 infrared spectrometer (KBr pellet); Bruker AVANCE III HD 400 nuclear magnetic resonance instrument; Alliance e2695 gel chromatograph;Labsys EVO thermogravimetric analyzer; OWC-2250B atmospheric thickening instrument; ZNN-D6 type six speed rotational viscometer; TG-8040B High Temperature and High Pressure Thickener; NYL-300 pressure testing machine;Malvern Zetasizer Nano ZS90 Nano Particle Size and Zeta Potential Analyzer; Thermo ES-CALAB 250XI X-ray photoelectron spectrometer; X Pert PRO MPD X-ray diffractometer.

Methyl allyl alcohol polyethylene glycol ether (HPEG, industrial product, Liaoning Oak Chemical Co., Ltd.);Acrylic acid (AA), ammonium persulfate (APS), mercaptoacetic acid (TGA), and sodium hydroxide are all analytical grade (Chengdu Kelong Chemical Reagent Factory);Methacryloyloxyethyltrimethylammonium chloride (DMC, 60% aqueous solution, Shanghai Aladdin Biochemical Technology Co., Ltd.);G-grade oil well cement (industrial product, Jiahua Special Cement Co., Ltd.); Deionized water (laboratory made); Mixing water (laboratory tap water).

1.2 Synthesis and Characterization of Dispersants

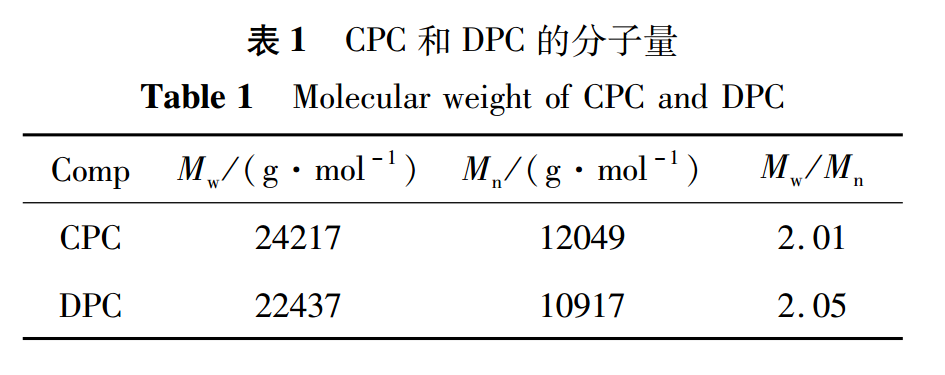

Conventional anionic polycarboxylates (CPC) and zwitterionic polycarboxylates (DPC) are obtained through free radical aqueous solution polymerization reaction.The ratio of the amounts of HPEG and AA reactants in CPC is 1:5, while the ratio of HPEG, AA, and DMC reactants in DPC is 1:3:2. The structures of CPC and DPC are shown in Figure 1.The reaction conditions for both remain unchanged, with a monomer mass concentration of 40.0%, an initiator APS dosage of 2.0% of the total monomer mass, a chain transfer agent TGA dosage of 0.7% of the total monomer mass, a reaction temperature of 65 ℃, and a reaction time of 4 hours.

Taking the synthesis of DPC as an example, the specific steps are as follows: first, weigh 48.00g of HPEG and 0.46g of TGA and dissolve them in 50.00g of deionized water to prepare solution A.Weigh 4.32g of AA and 13.83g of DMC and dissolve them in 25.00g of deionized water to prepare solution B.Weigh 1.32g of APS and dissolve it in 20.00g deionized water to prepare solution C for later use.Then add solution A to a four necked flask, stir and introduce nitrogen gas for 20 minutes before heating to 65℃.Add solutions B and C dropwise for 3.0 and 3.5 hours, respectively, and then incubate and age for 0.5 hours before ending the reaction.After cooling to room temperature, add 40% (mass fraction) sodium hydroxide to adjust the pH to 6-8 to obtain a light yellow slightly viscous solution. After drying, grind to obtain DPC solid powder.

The infrared spectrum, nuclear magnetic resonance hydrogen spectrum, gel permeation chromatography and thermogravimetric analysis of CPC and DPC shall refer to the literature.

1.3 Preparation and Performance Evaluation Method of Cement Slurry

Cement slurry formula: Jiahua G-grade cement+dispersant, water to solid ratio of 0.44:1.00, density of 1.90g/cm3.

The preparation, rheological properties, thickening properties, and compressive strength of cement slurry are tested according to the methods described in GB/T19139-2012 "Test Methods for Oil Well Cement" and SY/T5504.3-2018 "Evaluation Methods for Oil Well Cement Admixtures Part 3: Drag Reducing Agents". The flowability of cement slurry is tested according to the methods described in GB/T8077-2012 "Test Methods for Homogeneity of Concrete Admixtures".

2. Results and Discussion

2.1 Polymer Characterization Analysis

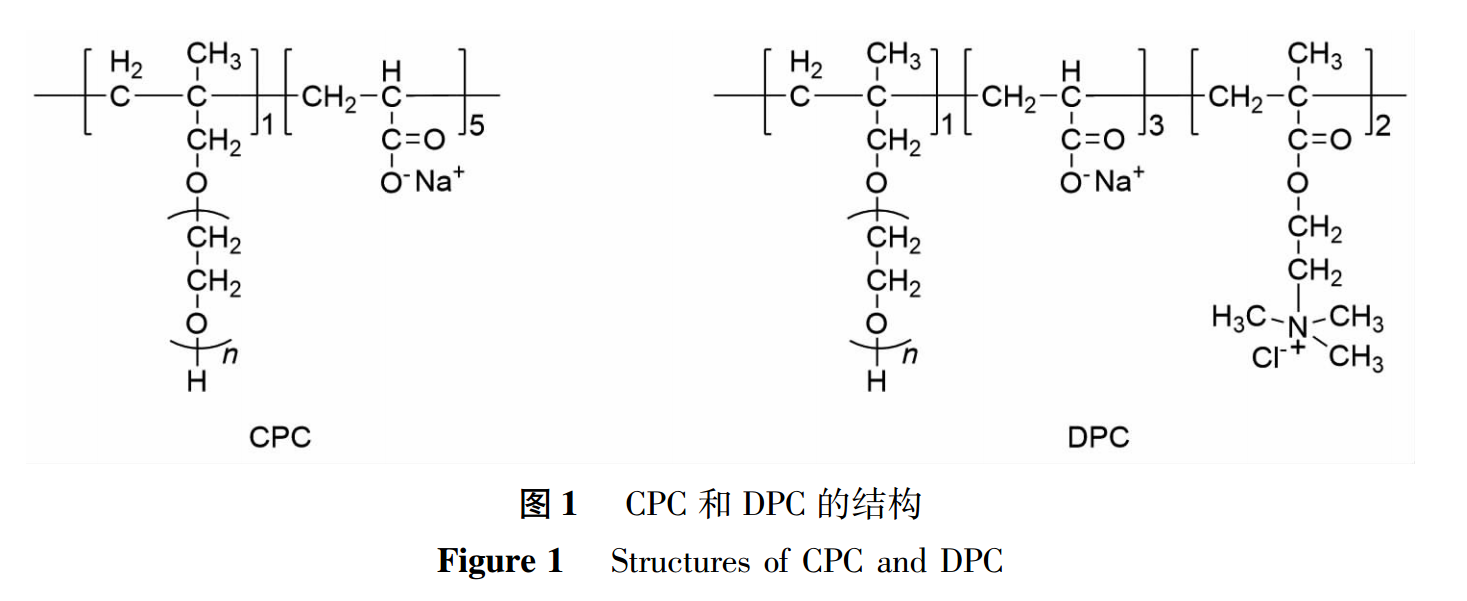

(1) Infrared Spectroscopy Analysis

The infrared spectra of HPEG, CPC, and DPC are shown in Figure 2.There are characteristic absorption peaks in the infrared spectrum of HPEG, including hydroxyl (-OH, 3456cm-1), methyl and methylene (-CH3 and -CH2, 2879cm-1), carbon carbon double bond (C=C, 1656cm-1), and ether bond (O-C-O, 1110cm-1).The characteristic absorption peaks of carbon carbon double bonds from HPEG disappeared in both CPC and DPC, while there was a characteristic absorption peak of carboxyl group (-COOH, 1725cm-1) in CPC, and not only carboxyl group but also quaternary ammonium salt ion (-N+(CH3) 3, 1301 cm-1) in DPC, indicating that CPC is a binary polymer of HPEG and AA, and DPC is a ternary polymer of HPEG, AA, and DMC.

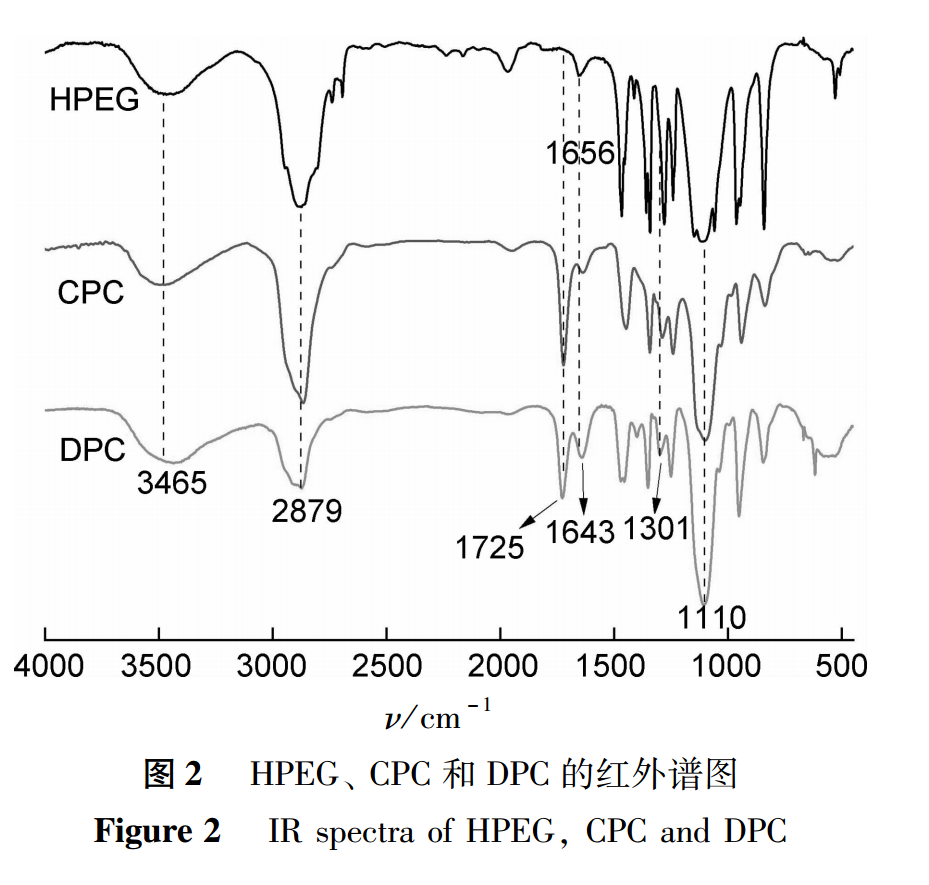

(2) Nuclear Magnetic Resonance Hydrogen Spectroscopy Analysis

The hydrogen nuclear magnetic resonance spectra of monomer HPEG and its polymers CPC and DPC were tested, and the results are shown in Figure 3.The proton peak at δ 5.09 is attributed to the hydrogen on the carbon carbon double bond of HPEG, while the strong and broad proton peak at δ 3.50-4.00 is attributed to the hydrogen on HPEG polyethylene glycol,After polymerization, the carbon carbon double bond becomes a single bond, so the peaks of polymer CPC and DPC at δ 5.09 disappear;The strong peak at δ 3.10~3.50 is attributed to the hydrogen on the methyl group connected to the quaternary ammonium salt ion in DPC;The hump at δ 2.20-2.50 belongs to the hydrogen on the main chain carbon directly connected to the carboxyl group.The camel hump intensity of DPC is lower than that of CPC, which is caused by the decrease in the proportion of carboxyl groups in the synthetic raw materials.By comprehensively analyzing the infrared spectrum and nuclear magnetic resonance hydrogen spectrum, the synthesized polymers CPC and DPC were determined as the target products.

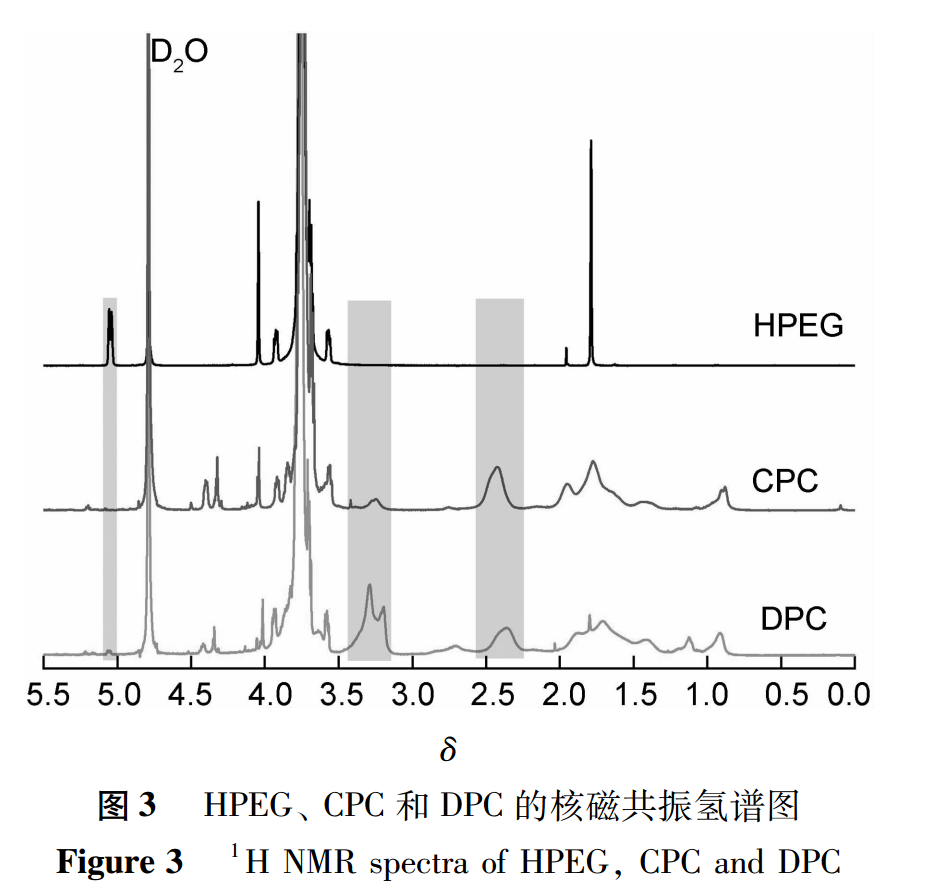

(3) Gel Permeation Chromatography (GPC) Analysis

If the molecular weight of the polymer is too large, there is a risk of viscosity increase, which is not conducive to the dispersion of cement particles.The molecular weight of CPC and DPC is tested by gel permeation chromatography.According to Table 1, the weight average molecular weight (Mw) of CPC is 24217 g·mol-1, the number average molecular weight (Mn) is 12049 g·mol-1, and the distribution index (Mw/Mn) is 2.01.The weight average molecular weight (Mw) of DPC is 22437 g·mol-1, the number average molecular weight (Mn) is 10917 g·mol-1, and the distribution index (Mw/Mn) is 2.05.The molecular weight and distribution index of CPC and DPC are moderate, within the molecular weight range of dispersants.