Study on the Influence of Wax Content on the Phase Characteristics of Formation Fluids in Condensate Gas Reservoirs(Part 1)

Abstract

In response to the problem of significant differences in wax content among fluids from multiple wells in the Dabei condensate gas field and unclear understanding of the impact of wax content on the phase characteristics of formation fluids in condensate gas reservoirs, a method for producing formation fluid samples with different wax contents was established. Formation fluids with different wax contents were compounded, and experiments were conducted to investigate the effect of wax content on the phase characteristics of formation fluids in condensate gas reservoirs.The experiments found that as the wax content increases, the content of heavy components in flash oil and formation fluid components increases, the density of condensate oil increases, and the changes in flash gas components are relatively small;The dew point pressure of the formation fluid in the condensate gas reservoir increases with the increase of wax content. For every 1% increase in wax content, the dew point pressure increases by 0.2642 MPa; The retrograde condensation of heavy hydrocarbon components in condensate gas and the loss of formation retrograde condensate oil increase with the increase of wax content, resulting in an increase in the saturation of retrograde condensate liquid in the formation fluid of the condensate gas reservoir and a decrease in the degree of condensate oil recovery.The research results can provide guidance for the development of high wax condensate gas reservoirs, the improvement of wax deposition prediction models, and the optimization of wax removal and prevention technology.

Kuqa Depression in the Tarim Basin is rich in condensate oil and gas resources, mainly including Bozi, Dabei, Dina and Tuziluoke gas condensate fields. The wax content of crude oil in Dabei gas condensate field varies greatly, with the highest wax content of 22% and the lowest wax content of 3%.As the temperature decreases, wax molecules in the fluid of the waxy formation precipitate and deposit on the inner wall of the wellbore, blocking the flow channel and reducing the flow diameter, resulting in a decrease or shutdown of the condensate gas well production.Therefore, it is urgent to further clarify the influence of wax content on the phase characteristics of condensate gas reservoirs. At present, most of the research on the phase characteristics of condensate gas reservoirs at home and abroad focuses on wax precipitation points, wax deposition, genesis of high and low wax content, wax removal and prevention methods, and wax deposition prediction models.For example, Yang Yongcai et al. analyzed the distribution characteristics of high wax condensate oil or light oil, revealing the formation mechanism of wax condensate gas reservoirs; Hu Yongle et al. used a high-pressure phase testing device to study the phase characteristics of high wax content condensate gas, and found that the color exhibited by high wax content condensate gas changed with phase changes under different pressure conditions;Zhong Taixian and others studied the phase diagram changes of wax containing condensate gas reservoirs and analyzed the wax precipitation mechanism from both experimental and theoretical perspectives.Yu Huajie et al. analyzed the phase characteristics of high CO2 condensate gas and found that CO2 helps to suppress the retrograde condensation of condensate oil and enhance its retrograde evaporation.Due to different wax contents, the phase characteristics of condensate gas reservoirs vary, resulting in different wax deposition amounts in the wellbore. However, there is currently no relevant research on the influence of wax content on the phase characteristics of condensate gas reservoirs.Therefore, this article uses oil and gas samples from well 1101 in the Dabei condensate gas field to establish a method for producing fluid samples from formations with different wax contents. The composition and content, dew point pressure, deviation coefficient, and phase characteristics of fluids from formations with different wax contents in the Dabei condensate gas field were studied, in order to provide guidance for formulating reasonable development methods for condensate gas reservoirs and improving the recovery rate of condensate oil.

1. Methods for Producing Fluid Samples from Formations with Different Wax Contents

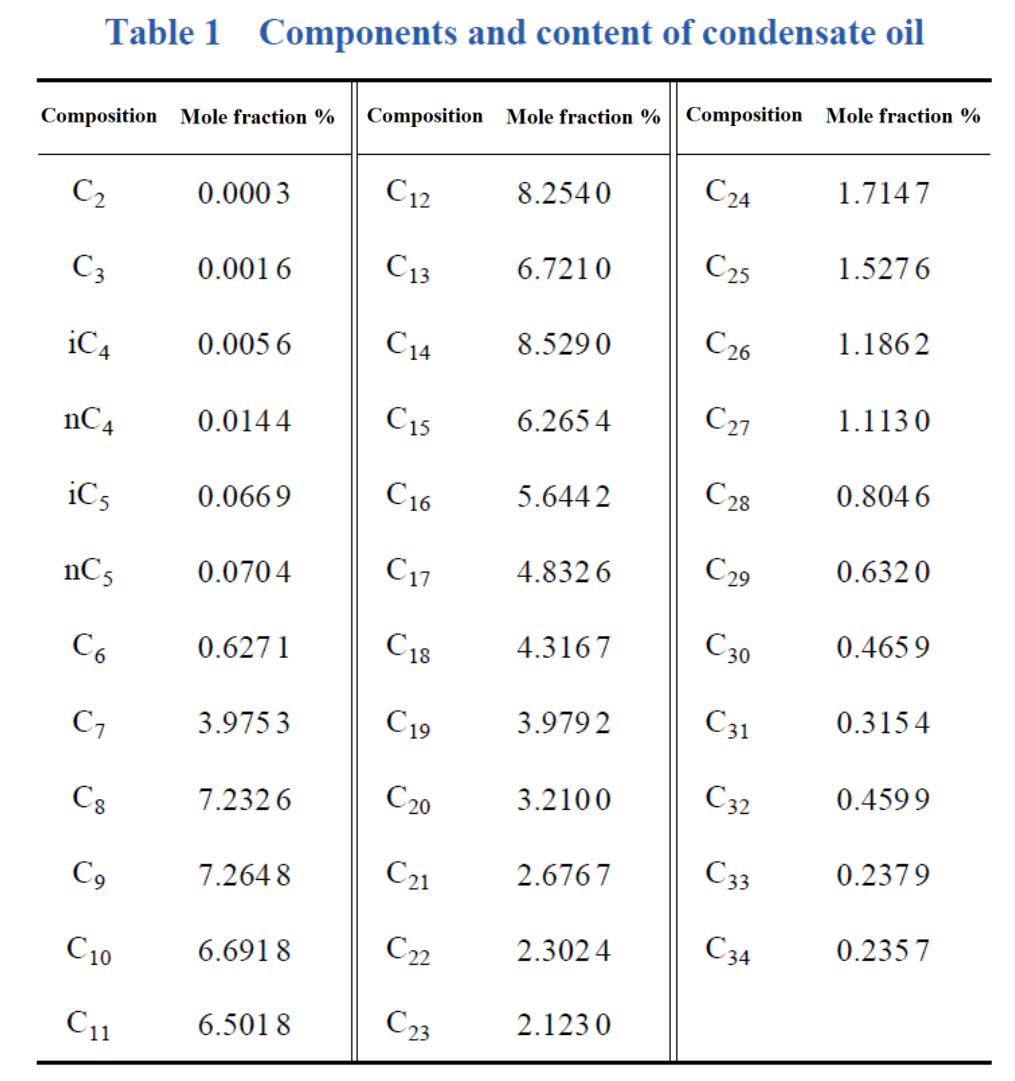

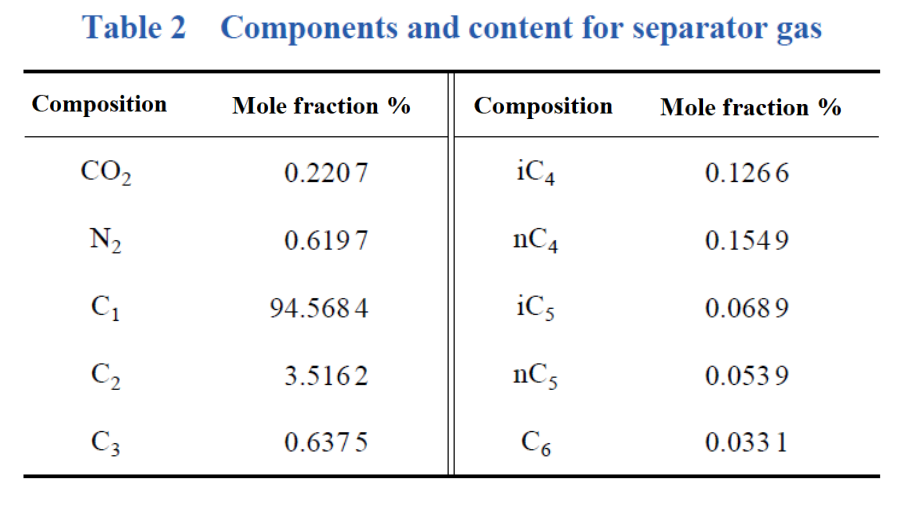

This article uses the gas separated from the surface condensate oil and separator of well 1101 in the Dabei condensate gas field to obtain formation fluids by compounding according to the production gas oil ratio. When sampling, the separator temperature was 44℃, the pressure was 14.787 MPa, and the on-site production gas oil ratio was 25 421.62 m3/m-3.The analysis results of surface condensate oil and separated gas components are shown in Tables 1 and 2. According to Table 1, components above C11 account for 74.0489% of the condensate oil. According to Table 2, methane accounts for 94.5684% of the separated gas.In order to study the effect of wax content on the phase characteristics of formation fluids in condensate gas reservoirs, it is necessary to ensure that the wax content in the condensate oil is reduced or increased without changing the production gas oil ratio. For condensate oil samples obtained at the separator, the method is to reduce or increase the wax content of the prepared condensate oil by adding light oil or high wax condensate oil from the well itself.

High wax condensate oil is obtained by distilling to remove light oil from the condensate oil. Mix the high wax condensate oil with the condensate oil obtained from the separator in a certain proportion, and refer to the standard "Determination of Wax, Gum, and Asphalt Content in Crude Oil" (SY/T 7550-2012) to test the wax content of the mixed condensate oil. Prepare condensate oil samples with wax contents of 7.04%, 12.08%, 17.79%, and 27.77%, respectively.According to the on-site production gas oil ratio and in accordance with the standard "Methods for Analyzing Fluid Properties in Oil and Gas Reservoirs" (GB/T26981-2020), condensate oil samples with different wax contents were compounded with separated gas samples to obtain formation fluid samples with different wax contents.

2. Phase Characteristics of Fluids in Formations with Different Wax Contents

Analyze the influence of wax content on the phase characteristics of formation fluids through phase tests of formation fluids. According to the standard "Methods for Analyzing the Physical Properties of Oil and Gas Reservoir Fluids" (GB/T 26981-2020), phase tests of formation fluids are conducted, which mainly include flash evaporation test, constant mass expansion test, and constant volume depletion test.

2.1 Characteristics of Flash Evaporation Components of Formation Fluids with Different Wax Contents

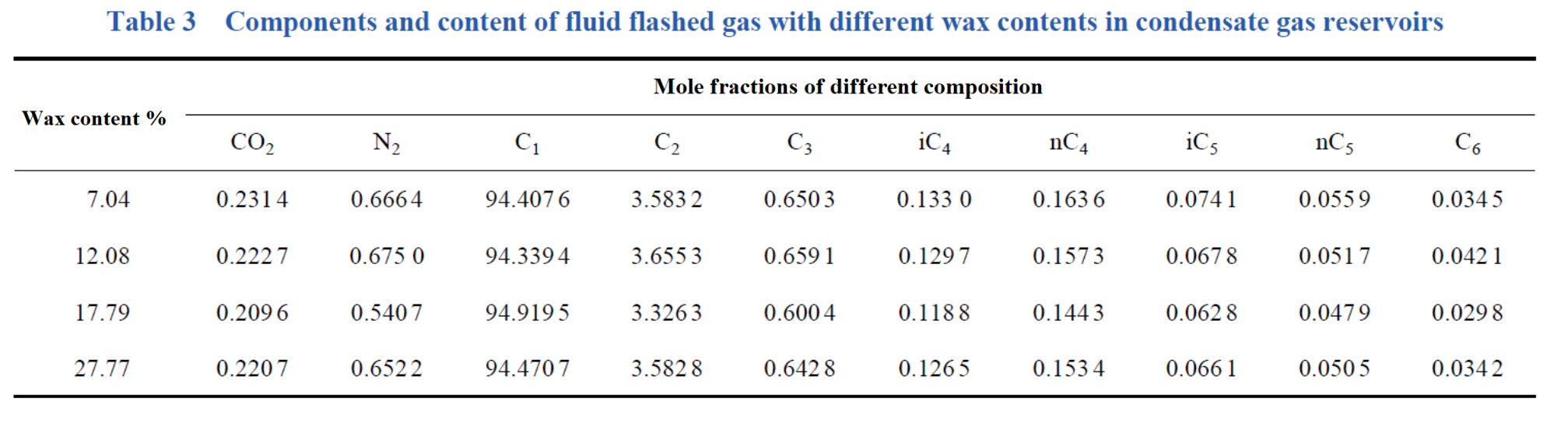

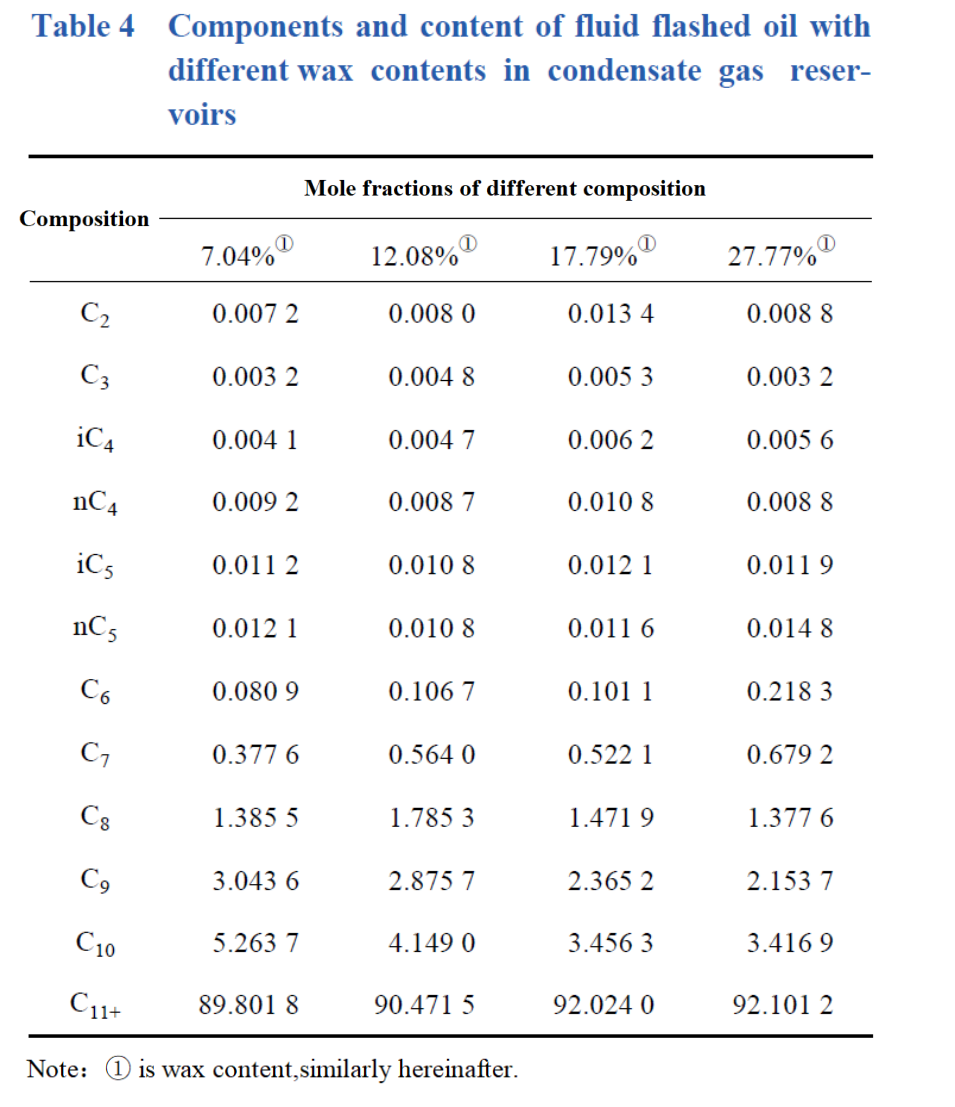

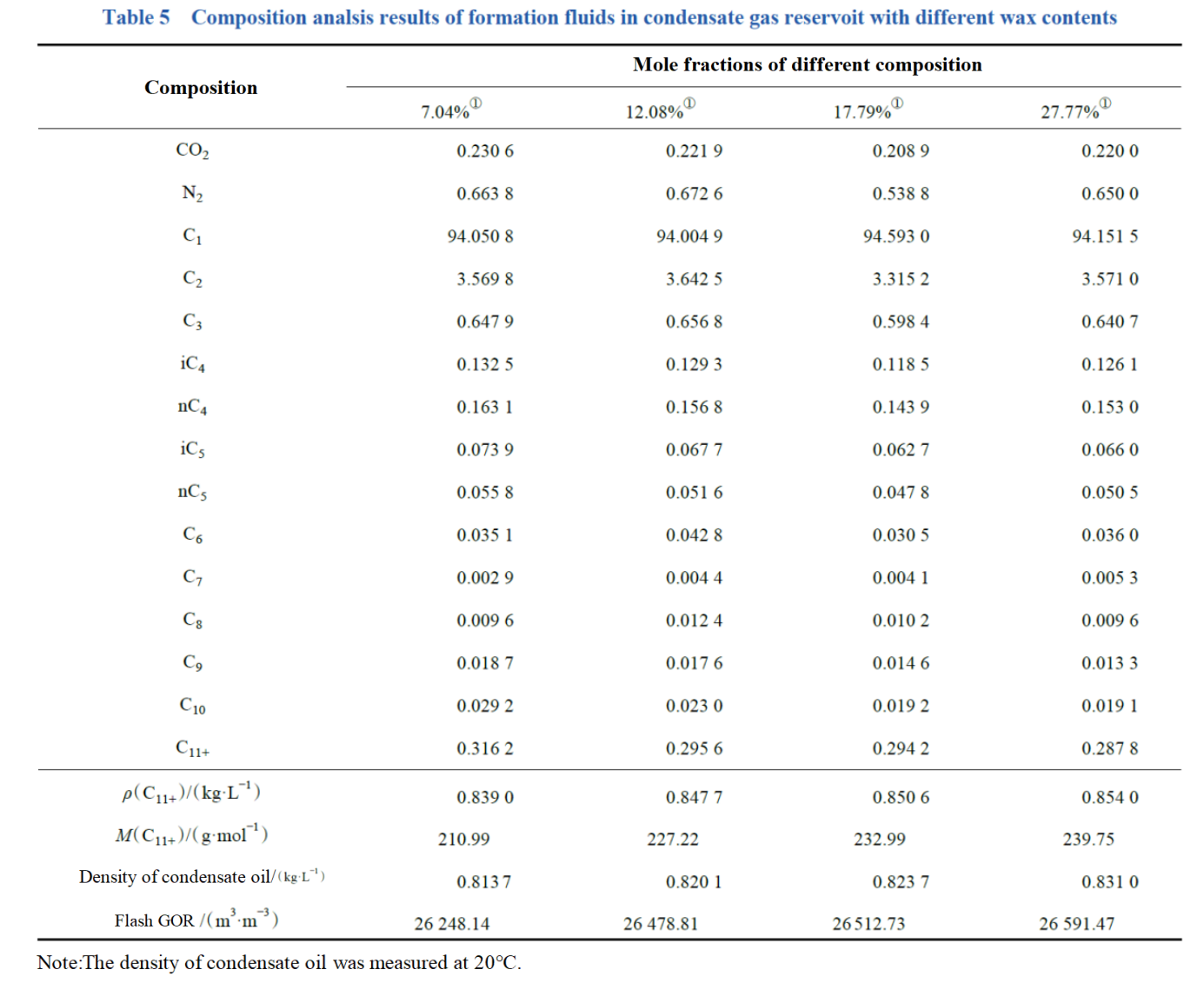

Single flash evaporation experiments were conducted on formation fluid samples with different wax contents using flash separators and gas chromatographs. The analysis results of flash vapor, flash oil, and formation fluid components are shown in Table 3-Table 5.

From Table 3, it can be seen that the composition and content of fluid flash gas in formations with different wax contents do not change significantly. This is because the wax in the condensate oil of this well is mainly composed of heavy components above C11, while the flash gas is mainly composed of light components below C6.

From Table 4, it can be seen that when the wax content in the local fluid is 7.04%, 12.08%, 17.79%, and 27.77%, the corresponding mole fractions of heavy components above C11 in the flash oil are 89.801 8%, 90.471 5%, 92.024 0%, and 92.101 2%, respectively. It can be seen that the higher the wax content, the higher the content of heavy components in the flash oil.

From Table 5, it can be seen that when the wax content in the formation fluid is 7.04%, 12.08%, 17.79%, and 27.77%, the molecular weights of heavy components above C11 in the formation fluid are 210.99, 922, 7.22, 232.99, and 239.75 g/mol, respectively. The condensate densities are 0.8137, 0.8201, 0.8237, and 0.831kg/L, respectively. The flash gas to oil ratios are 26 248.14, 26 478.81, 26 512.73, and 26 591.47 m3/m-3.From this, it can be seen that the higher the wax content, the higher the quality of heavy components in the formation fluid, and the corresponding density of condensate oil. The variation patterns of various components in formation fluids with different wax contents were clarified through a single flash evaporation test, providing support for further understanding the phase transition characteristics of high wax condensate gas reservoirs.