Solar High-temperature Photothermal Technology Empowers Low-carbon Development of Shallow Ultra Heavy Oil (Part 3)

4. Photothermal Solution for Large-scale Development of Heavy Oil Operation Areas

The above two plans mainly focus on replacing heat with renewable energy supply in developed heavy oil operation areas. For heavy oil operation areas with large-scale new production capacity, it is necessary to systematically configure low-carbon energy supply solutions, integrate development with new energy while ensuring energy supply, and consider economic requirements. To this end, a photothermal/photovoltaic coupled gas turbine cogeneration scheme is proposed, which can maximize the demand for clean electricity and heat in the newly added production capacity of the work area. Based on the following guiding principles, carry out the configuration of low-carbon energy supply schemes.

① The changes in light resources in the same region are basically consistent with the output curves of solar thermal steam and photovoltaic power generation.

② Gas turbine cogeneration technology is mature and belongs to clean energy supply. Its heating and power generation output can be quickly adjusted synchronously with changes in gas turbine load.

③ Coupling photothermal, photovoltaic, and gas turbine to achieve cogeneration matching. During the day, carbon free steam and electricity are provided to the oil field through solar energy, while gas turbine cogeneration units serve as peak shaving and nighttime base load supply. Peak shaving and valley filling serve as ballast stones for renewable energy.

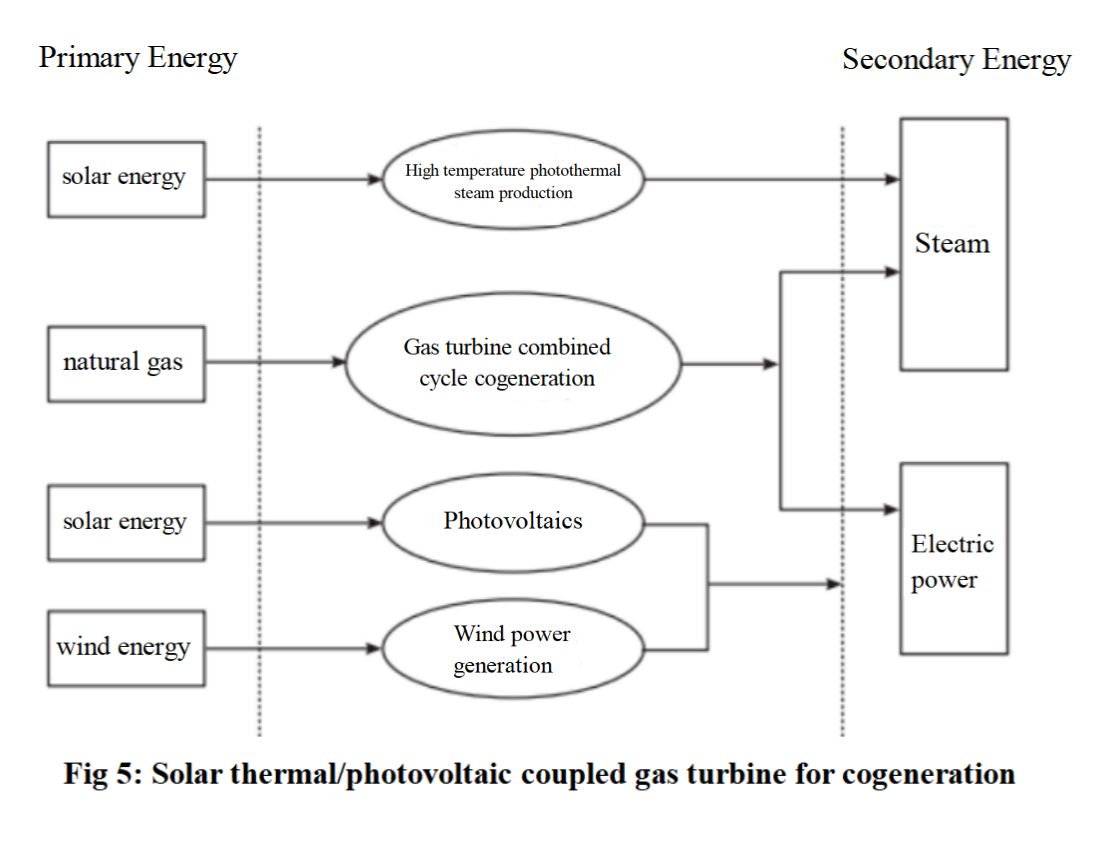

At present, primary energy sources such as solar energy, natural gas, and wind energy are mainly converted into secondary energy (such as steam and electricity) for utilization through technologies such as high-temperature photothermal, gas turbine cogeneration, photovoltaic power generation, and wind power generation. The conversion process is shown in Figure 5. The main energy sources for heavy oil development are steam and electricity. Therefore, coupling technologies such as high-temperature photothermal steam production, photovoltaic power generation, and gas turbine cogeneration can be considered to provide steam and electricity for heavy oil development through multi energy complementarity.

The heavy oil operation area planned to be developed by Xinjiang Oilfield Company adopts solar energy, and the basic operating mode is as follows.

① The solar thermal steam system operates at high load during the day, and the gas turbine can adopt a mode of one operating and one standby.

② When the solar thermal steam system is switched to low load or shut down, the steam supply capacity can be improved by increasing the output of the gas turbine or starting another gas turbine.

③ The gas turbine adopts a thermal to electric operation mode, coupled with a photothermal steam system to provide the required steam for the operation area, as the steam supply for peak shaving, while also taking into account the peak shaving of the power grid.

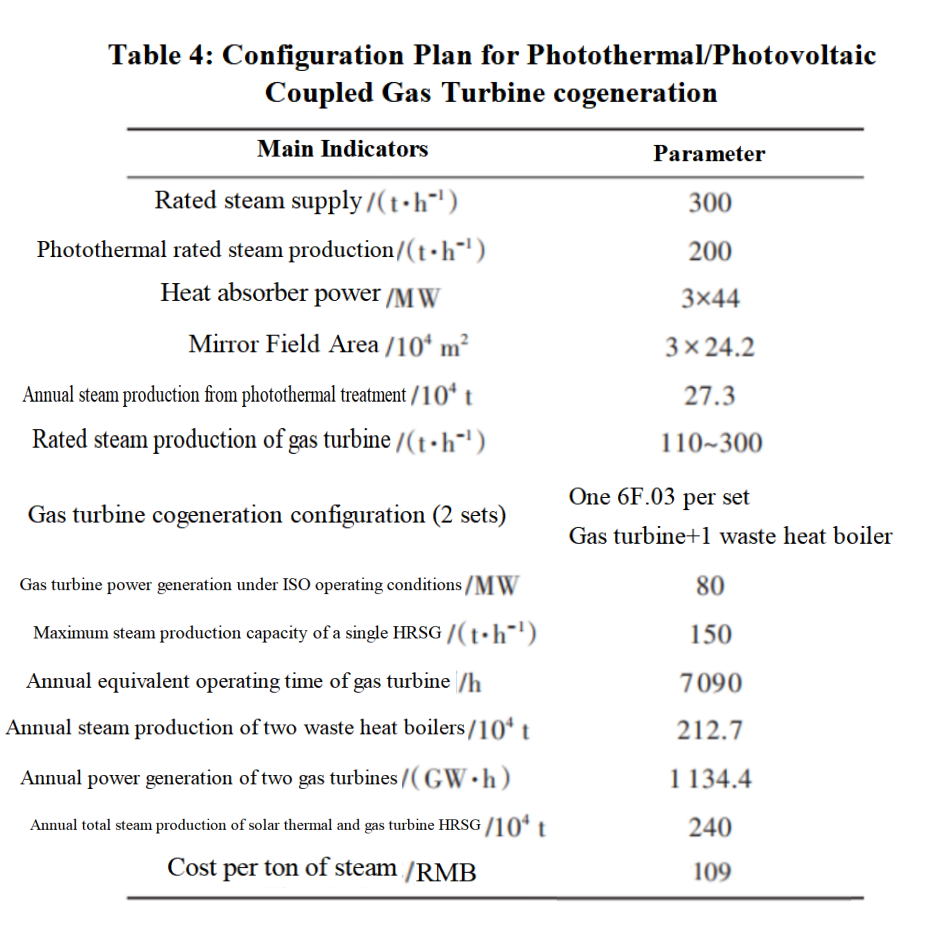

By optimizing the system with the goal of fully utilizing solar energy and maintaining stable overall steam supply, the energy supply facility parameters of solar thermal+gas turbine cogeneration coupled steam supply were configured, as shown in Table 4.

By using the photothermal/photovoltaic coupled gas turbine cogeneration method, large-scale and reliable energy supply has been achieved in heavy oil operation areas, improving the cleanliness of energy supply facilities and effectively integrating with new energy while maintaining existing steam supply costs. The scheme configuration can flexibly couple the molten salt electric heating device according to the steam power demand, configure the molten salt heat storage method, and configure different scales and quantities of gas turbines according to the energy supply scale. For example, for work areas with a steam demand of 150-200 t/h, one set of gas turbine cogeneration system, one set of 44 MW CS-DSG system, or 1-2 sets of CS-SGS system coupled with electric molten salt heaters can be configured; For the operation area with a steam demand of 100-150 t/h, a small-scale gas turbine configuration is adopted to achieve thermoelectric matching.

5. Conclusions and Recommendations

The application of photothermal technology in heavy oil thermal recovery is to convert solar energy into thermal energy using high-temperature solar concentrated heat collection technology, replacing the combustion of coal and natural gas to produce high-quality steam, which is used for steam injection in heavy oil thermal recovery, achieving renewable energy substitution for heavy oil steam flooding.

1). For developed blocks, especially heavy oil operation areas using SAGD development method, utilizing the heat storage capacity of forming underground steam chambers, CS-DSG technology is prioritized at this stage, coupled with existing steam injection boilers for combined steam supply and variable flow steam injection at the wellhead.

2). For heavy oil operation areas using steam flooding or steam huff and puff development methods, relying on the green electricity, curtailment electricity, and valley electricity resources generated by surrounding wind and photovoltaic power, CS-SGS technology is adopted, coupled with high-temperature concentrated light collection and electric heating, matched with molten salt heat storage systems to produce steam. On the basis of reducing steam costs, renewable energy is continuously used to provide steam for heavy oil extraction.

3). For heavy oil production areas with new production capacity, in combination with the national requirements for the construction of a demonstration project for synchronous development and comprehensive utilization of oil, gas, and solar energy, as well as the production plan for Xinjiang oil fields, a green, clean, and low-carbon steam and electricity supply will be provided to the oil fields through the combination of photothermal steam and photovoltaic power generation coupled with gas turbine cogeneration.

4). The cost of photothermal steam production is close to that of traditional gas-fired steam injection boilers. With the cost reduction and technological progress of photothermal steam production systems, it is expected that the cost of photothermal steam production will be on par with that of natural gas steam injection boilers in the next 3-5 years. The application of photothermal steam production in heavy oil thermal recovery has broad development prospects.