Simulation Experiment on Drag Reduction of Heavy Oil Mixed with Gas in Horizontal Pipes (Part 2)

2.2 Pipeline Reliability Analysis

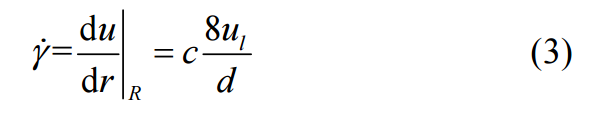

During the single-phase flow of white oil in the pipeline, it is in the laminar flow zone, and the fluid at the pipe wall flows in layers without mass exchange between layers. According to the theory of fluid mechanics, for the analysis of fluid equilibrium forces in the cross-section of a pipeline, the shear stress at the pipe wall is

The shear rate at the wall of the laminar flow zone is the effective shear rate of the liquid flowing through the pipe under the corresponding conditions. The effective shear rate of Newtonian fluid in laminar flow can be calculated using equation (3)

Analyze the flow characteristics of heavy oil pipelines in horizontal testing sections and evaluate the accuracy and effectiveness of the pipeline flow testing system. The relationship between shear stress and shear rate of two types of white oil under single-phase flow in the annulus was obtained using equations (2) and (3), and compared with the results of rheometer tests at the same temperature, as shown in Figure 5.

From Figure 5, it can be seen that the simulated shear stress of the two types of white oil rings is generally higher than the rheometer test results. This may be due to the relatively low oil temperature at the contact surface when the oil comes into contact with the inner wall of the pipeline, resulting in higher shear stress at the same shear rate.However, the average relative deviation is within 20%, which indirectly verifies the high accuracy, effective test results, and good reliability of the loop simulation device under single-phase oil flow conditions within the allowable error range.

2.3 Flow Pattern Characteristics

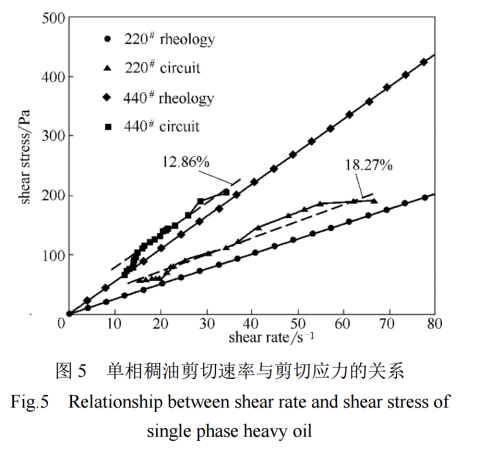

High speed cameras were used to capture the flow patterns of two types of white oil and air in pipelines at different blending ratios. The typical flow patterns are shown in Figure 6.Using 220# white oil as an example, when the flow rate of white oil is constant, with the increase of air flow rate or velocity, the flow patterns inside the pipe change in the following order: bubbly flow, slug flow, stratified flow, slug flow, annular flow, and misty flow.

When the gas-liquid ratio is less than 0.3, the flow pattern is mainly bubbly flow. The gas in the pipeline is distributed in the form of bubbles in the upper part of the pipeline, and the flow is relatively stable. The reason is that there is less gas, forming dispersed small bubbles with lower gas density, and suspending in the upper part of the oil to form bubbly flow;When the gas-liquid ratio is between 0.3 and 0.6, it is mainly a slug flow, with small bubbles gradually increasing and suspended in the upper part of the pipeline. The main reason for this is that as the gas volume increases, dispersed small bubbles converge into large bubbles, forming bubbles in the upper part of the pipeline and causing intermittent oil flow. At the same time, the bubbles push the oil forward.

When the gas-liquid ratio increases to 3.5-4.4, a circular flow appears in the pipeline, where the oil phase adheres to the pipe wall and flows slowly, while the gas phase distributes in the center of the pipeline and flows faster. This is mainly due to the further increase in gas volume, which disperses the oil flow of the slug and forms a circular flow of oil flow at the edge of the central airflow.When the gas-liquid ratio increases to 4.4-15, the main flow in the pipeline is misty, mainly due to the oil attached to the pipe wall being blown away and mixed in the gas phase in the form of small droplets. When annular flow and misty flow occur, the oil phase flow rate is low, which is not conducive to the transportation of the oil phase.

Compared with 440# white oil, it was found that with the increase of viscosity, the range of gas mixing ratio for laminar flow became smaller. The main reason for this is that: on the one hand, as the viscosity increases, bubbly flow gathers to form stratified flow, requiring higher gas mixing volume; on the other hand, as the viscosity increases, interlayer shear stress increases, making it easier for the liquid to gather forward and fill the pipeline section, forming a slug.

According to relevant research and analysis of the above flow pattern results, the main factors affecting these flow pattern changes include interfacial tension between gas-liquid phases, pipe wall roughness, and liquid pipe wall contact angle.

2.4 Analysis of Pressure Drop Pattern

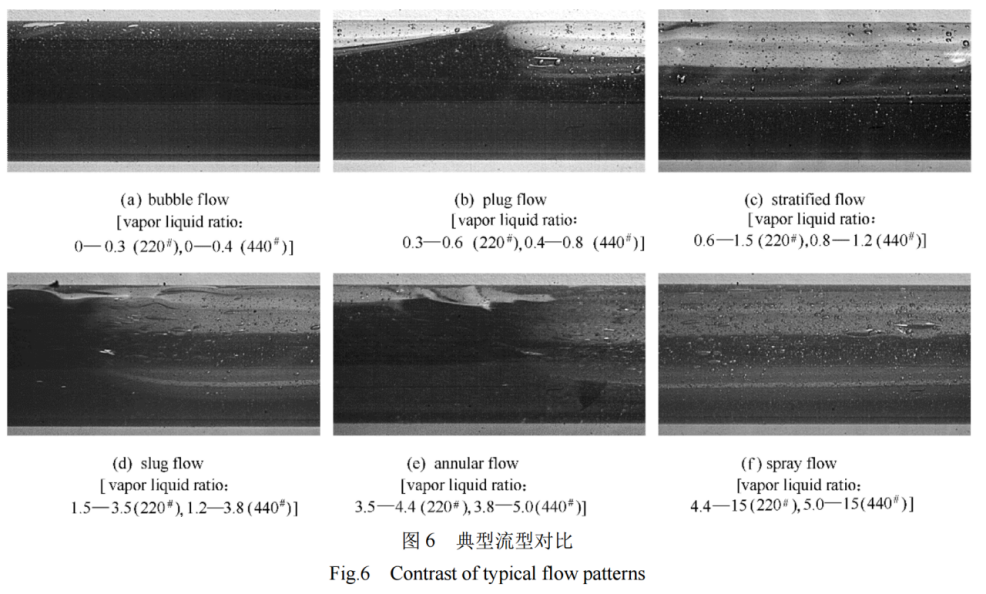

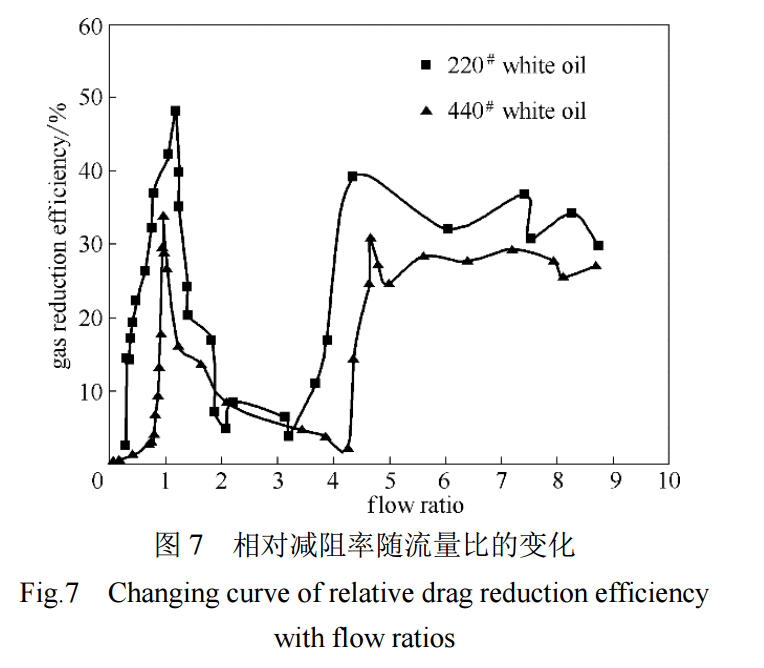

Calculate the relative drag reduction rate of 220# and 440# white oil in horizontal pipelines at different flow ratios according to equation (1), as shown in Table 1. Calculate and analyze the relative drag reduction rate, as shown in Figure 7.From this, it can be seen that with the increase of the blending ratio, the drag reduction rates of both types of white oils generally show an upward downward upward stable trend. As the viscosity of the oil increases, the overall drag reduction rate shows a downward trend.

Using 220# white oil as an example, when the gas-liquid ratio is below 0.3, the drag reduction effect is not significant with the increase of the blending ratio.The main reason is that the gas flow rate is too low, which not only fails to form a complete gas film layer between the oil walls, but also causes small bubbles to be dispersed and damaged by white oil, resulting in bubbly flow in the upper part of the pipeline. As a result, the viscosity and flow resistance during gas-liquid mixing do not decrease significantly. As the viscosity of the oil increases, the gas-liquid ratio shifts to the right under this trend.

When the gas-liquid ratio is in the range of 0.3 to 1.17, the drag reduction rate shows an increasing trend with the increase of the blending ratio, and the drag reduction rate can reach more than 20%. The flow patterns are mainly slug flow and stratified flow. As the gas flow rate increases, on the one hand, the gas film isolates the oil wall interface, effectively reducing the frictional resistance of the oil near the pipe wall flow interface layer. On the other hand, air transforms the oil oil contact into oil gas oil contact, reducing the interlayer shear stress of the mixed phase. The interaction between the two significantly increases the drag reduction rate.When the viscosity of the oil increases, the gas-liquid ratio range under this trend decreases.When the gas-liquid ratio is in the range of 1.17-3.5, the drag reduction rate decreases with the increase of the blending ratio, and the flow patterns are mainly stratified flow and slug flow. The main reason is that with the increase of air content, a slug flow gradually forms in the pipeline, increasing the pressure between the oil walls, thereby increasing the frictional resistance of the pipeline and the pressure drop instead. When the viscosity of the oil increases, the range of gas-liquid ratio under this trend increases.

When the gas-liquid ratio is greater than 3.5, the drag reduction rate first shows an upward trend with the increase of the blending ratio, and then tends to stabilize. The flow patterns are mainly annular flow and misty flow. At this point, the pipeline is filled with a large amount of gas, and the contact area between the gas walls gradually increases and tends to stabilize, thereby significantly reducing the frictional resistance of the pipeline.When the viscosity of the oil increases, the gas-liquid ratio shifts to the right under this trend. But in this working condition, the gas occupies too much of the circulation area, which is not conducive to the transportation of oil products.

Under the same operating conditions, the overall drag reduction rate of 220# white oil is higher than that of 440 # white oil, and the adjustable range of gas-liquid ratio is wider at the same drag reduction rate. In the process of heavy oil blending transportation, the drag reduction effect is better under the condition of gas-liquid ratio less than 2.When the gas-liquid ratio is 1.17, the drag reduction rate of 220# white oil is the highest, at 48.19%. When the gas-liquid ratio is 0.47-1.4, the drag reduction efficiency of the blended 220# white oil is higher than 30%; When the gas-liquid ratio is 0.96, the drag reduction rate of 440# white oil is the highest, reaching 33.76%. When the gas-liquid ratio is between 0.9 and 1.2, the drag reduction efficiency of blending on 440# white oil is higher than 20%. So, when the blending ratio of two types of white oil is 0.9-1.2, the drag reduction rate can both reach over 20%.