Research on Key Technologies and Equipment for Emergency Response to Oil and Gas Pipeline Leakage(Part 2)

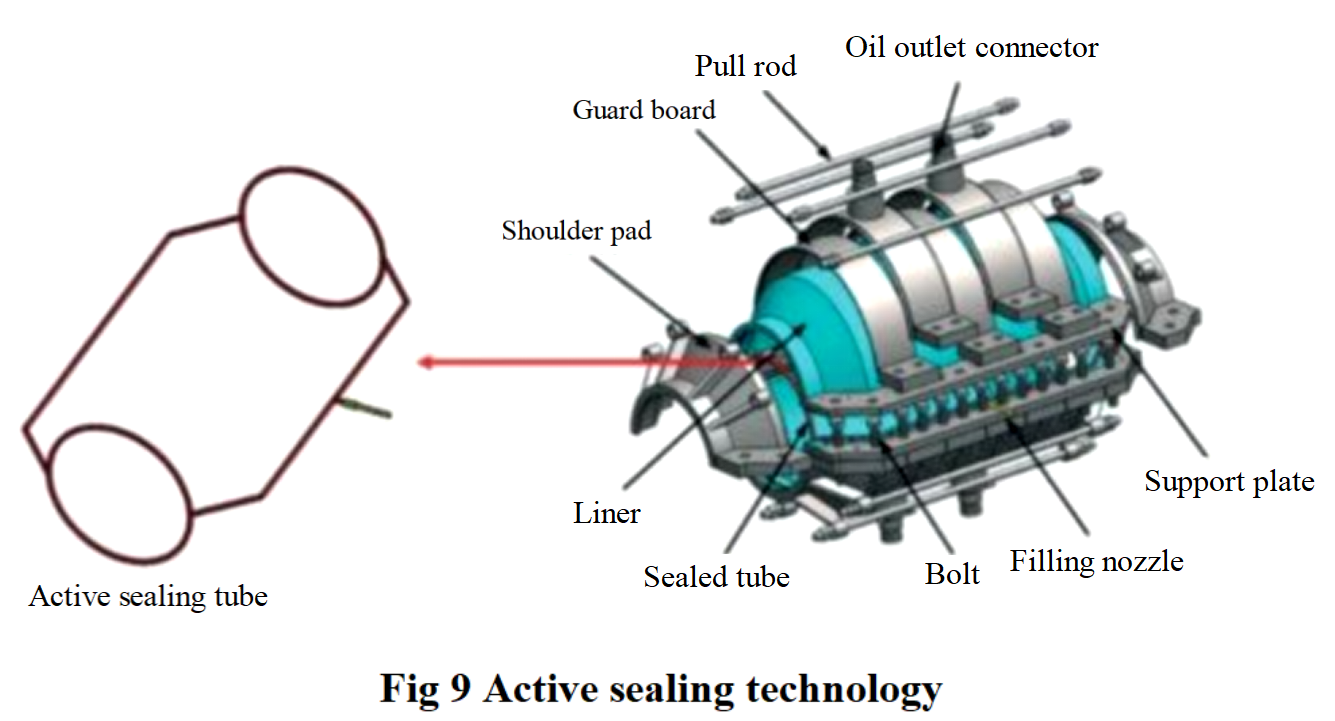

China University of Petroleum (Beijing) and Southwest Pipeline Company of the National Pipeline Network have proposed a large deformation flexible sealing technology for rapid leak prevention and emergency response of oil and gas pipelines without stripping the anti-corrosion layer (Figure 9).The core innovation of this technology lies in an active sealing method, which fills the sealing tube with pressure to ensure reliable contact between the sealing device and the pipeline anti-corrosion layer, thereby achieving rapid sealing of the leakage site without peeling off the anti-corrosion layer.This technology provides a new solution for emergency leak sealing under complex conditions, filling the gap in the field of leak sealing technology for large deformation damaged pipelines at home and abroad.

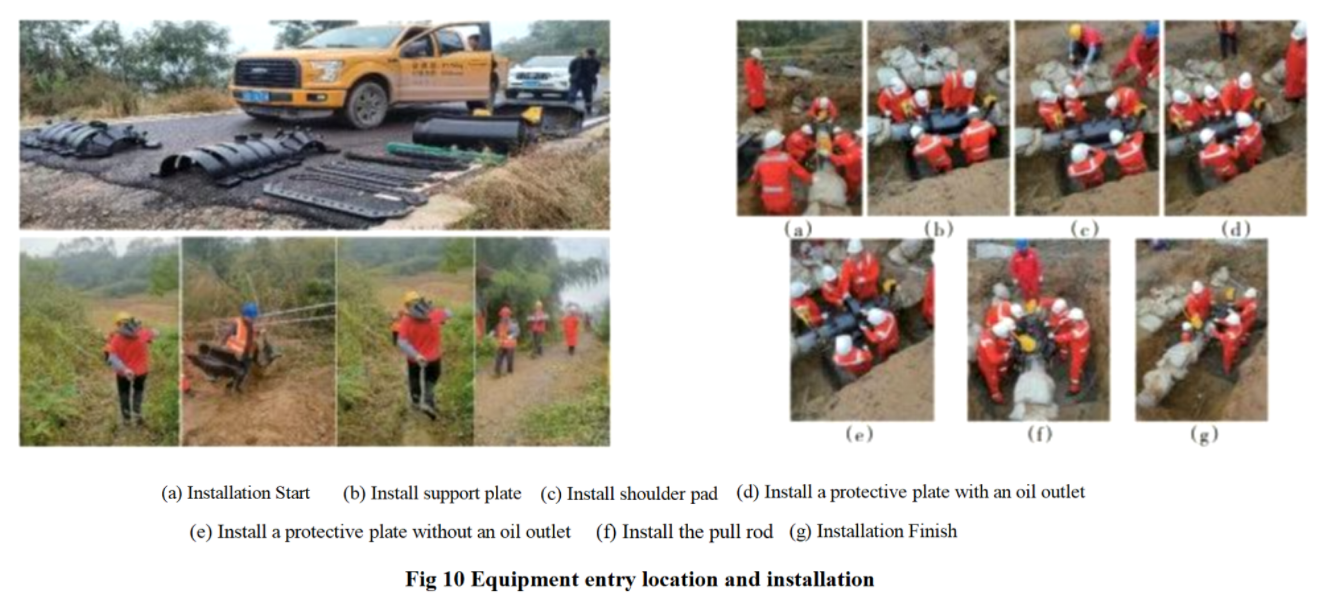

At the same time, this technology combines lightweight, modular, and portable equipment design to control the weight of individual components of the leak sealing equipment below 50 kg, making it easy for manual carrying and rapid on-site deployment, greatly reducing the difficulty of equipment entry, especially suitable for complex scenarios that are difficult for transportation vehicles to reach, such as mountains, water networks, tunnels, and crossing areas (Figure 10).Through modular structure, the equipment can flexibly adapt to different damage locations and leakage situations, ensuring efficient leak prevention.

2. Research Progress on Emergency Maintenance and Repair Technology and Equipment within the Management

2.1 Open Hole Sealing Spherical Double Sealing Technology and Equipment

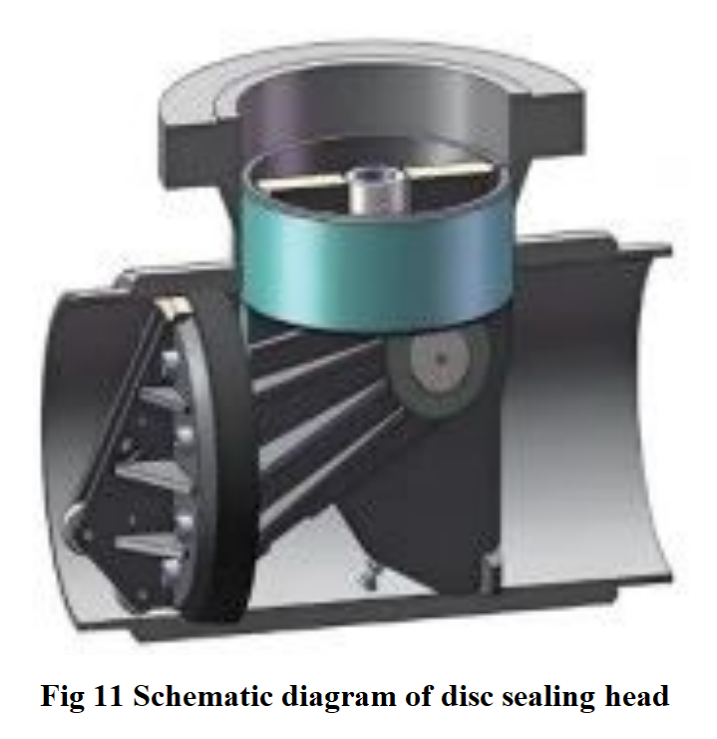

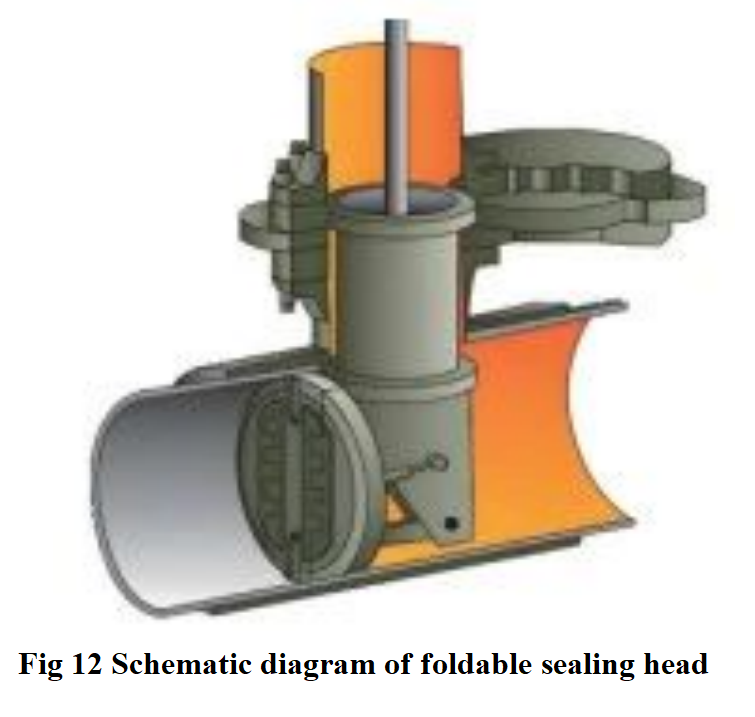

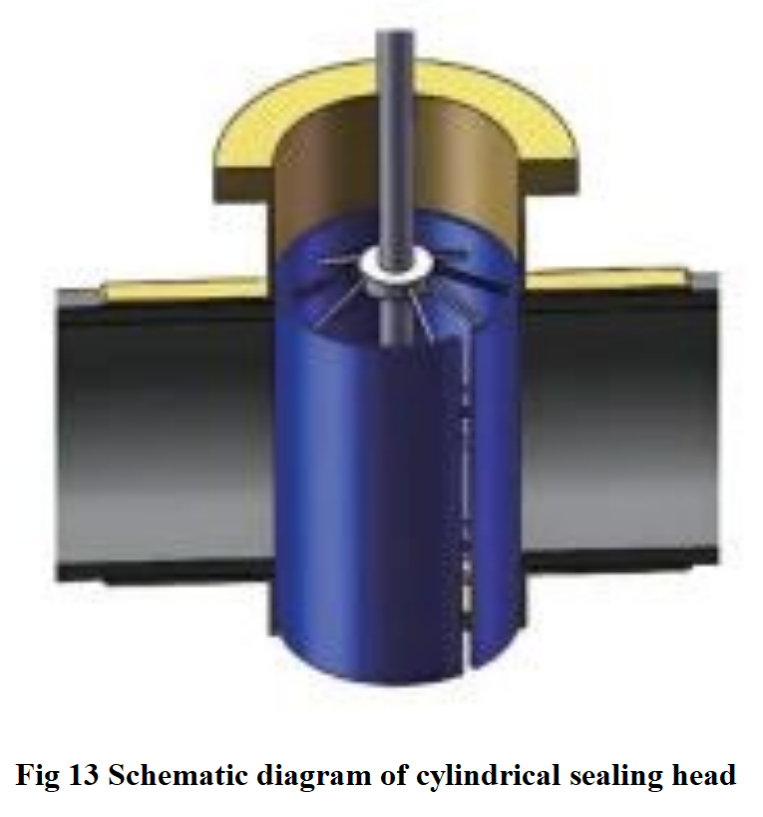

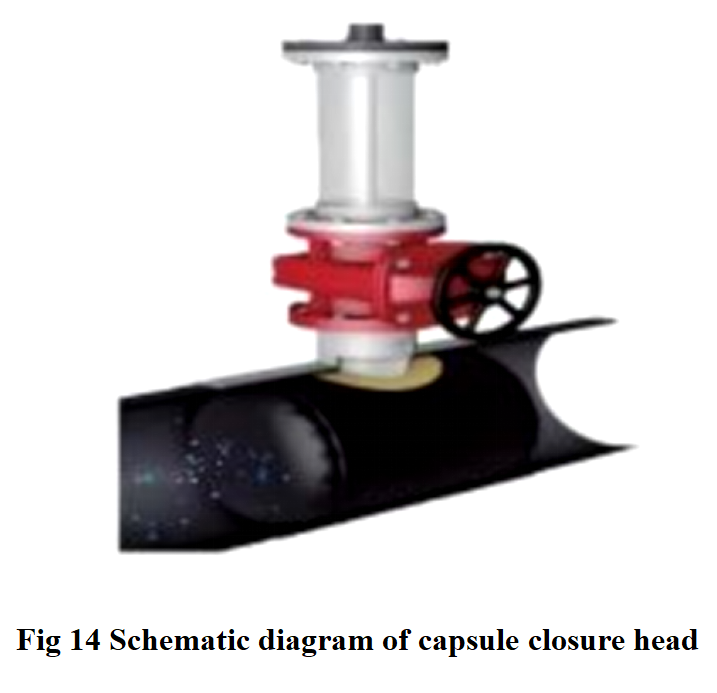

Pressure tapping and sealing technology is an emergency sealing method used for oil and gas pipelines, which can perform tapping and sealing operations on pipelines while maintaining a constant pressure inside the pipeline.The key to this technology is to use specialized pressurized drilling equipment to accurately drill holes in the pipeline while avoiding medium leakage inside the pipeline.The pressurized perforation sealing technology is widely used for rapid sealing of pipeline leaks, especially for high-pressure and hazardous medium pipeline systems.The matching sealing head is precisely inserted into the opening position through mechanical or hydraulic devices on the basis of pressurized opening, completing the sealing operation. These sealing heads usually have adaptive capabilities and can effectively seal according to the inner diameter, pressure, and damage morphology of the pipeline.According to different types of occluders, common methods of pipeline occlusion can be divided into disc occlusion, folding occlusion, tube occlusion, and balloon occlusion (Figure 11-14).

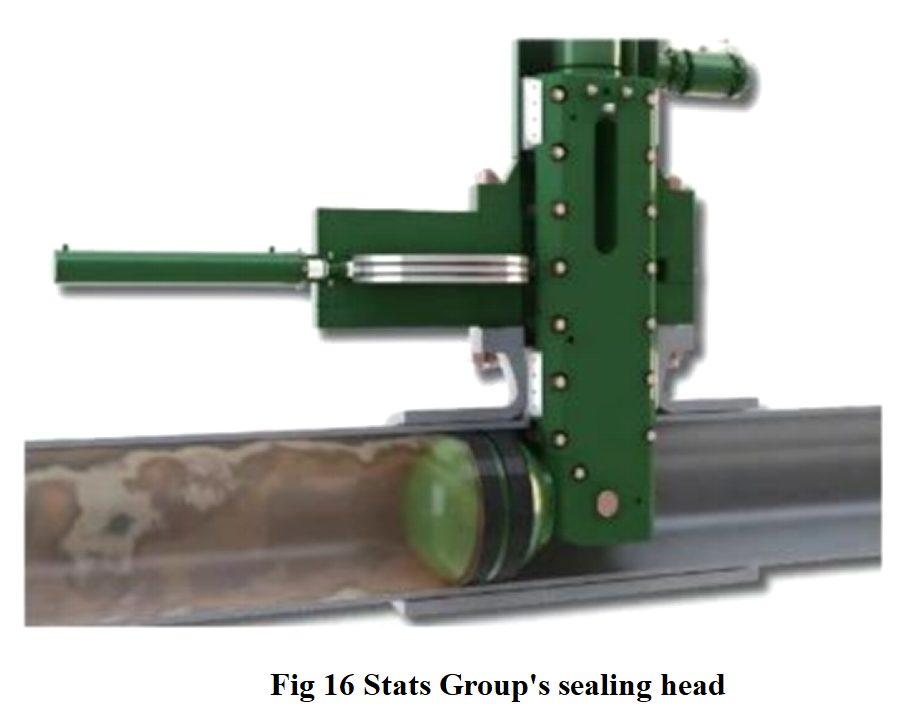

In the research field of spherical sealing heads, the ProStopp®DS sealing technology developed by T.D. Williamson is mainly applied to low-pressure gas transmission pipelines (Figure 15).In contrast, the BISEP sealing technology launched by Stats Group is suitable for high-pressure and large-diameter pipe scenarios (Figure 16).The application of these technologies has expanded the applicability of sealing operations and met the needs of different working conditions.

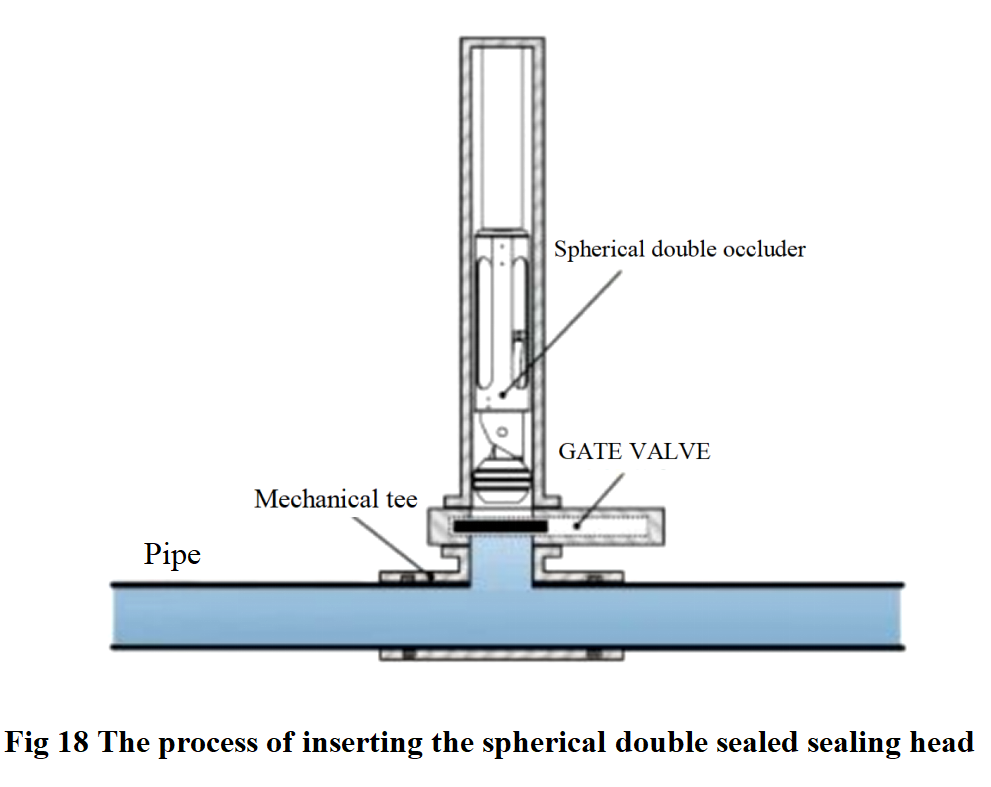

China University of Petroleum (Beijing) has developed a spherical double occluder (Figure 17, 18). The occluder adopts a spherical integrated structure design, with two sealant cylinders compressed by hydraulic cylinders integrated in the middle to achieve active occlusion through radial expansion.Research on automatic trajectory control for spherical double sealing of submarine pipelines to address the problem of pipeline blockage. Two control algorithms for automatic feeding of sealing heads were proposed, and it was found through simulation that the control algorithm based on vertical displacement has better performance than the control algorithm based on rotation angle.

2.2 Intelligent Sealing Technology and Equipment for Oil and Gas Pipelines

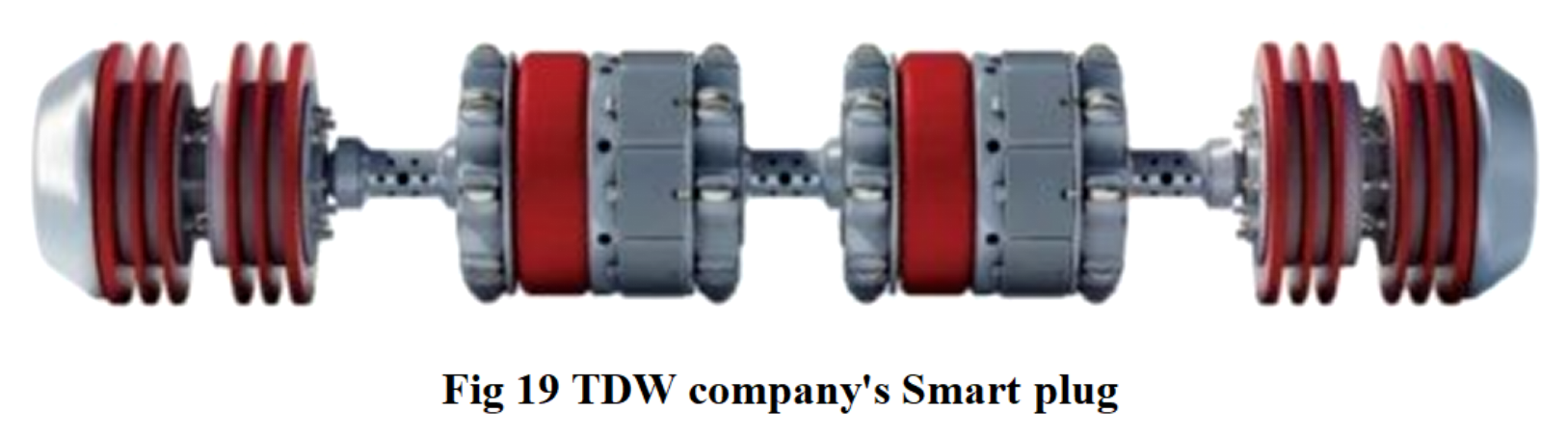

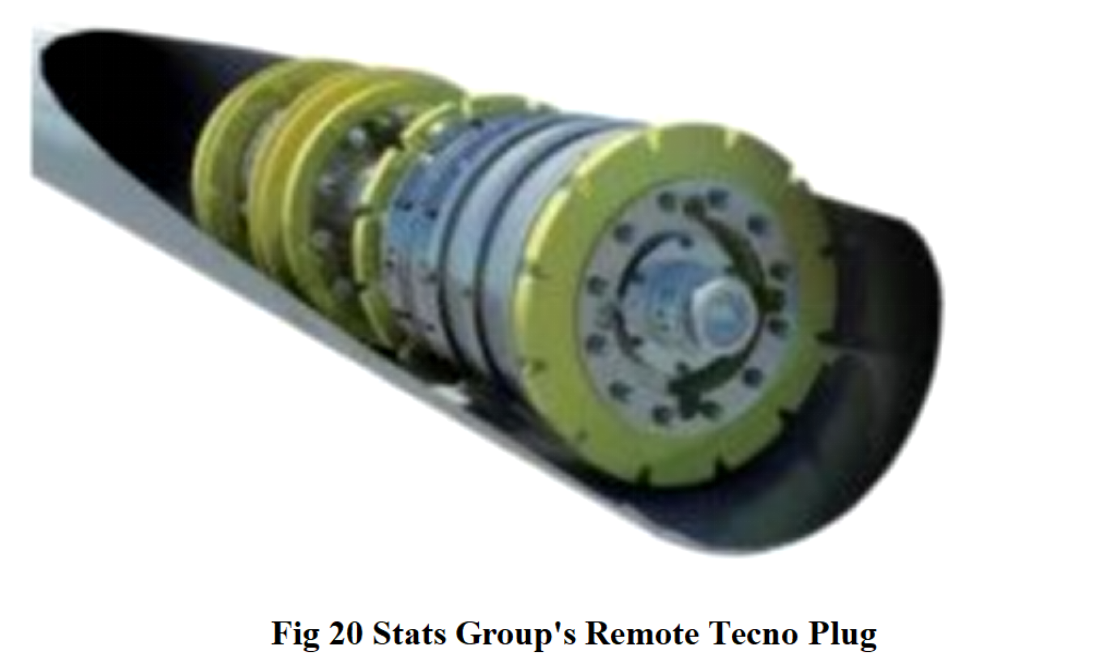

The high-pressure intelligent sealing technology inside the pipe is a new type of sealing method developed in the 1990s. The intelligent occluder enters the pipeline through the launching end, moves forward under the push of the medium, and reaches the target pipe section. After that, it controls the micro hydraulic system to drive the slip anchoring and rubber cylinder sealing through the ultra-low frequency electromagnetic pulse signal (ELF).After the homework is completed, the intelligent occluder automatically unlocks under ELF signal control and continues to move forward to the receiving end for removal. At present, this technology is mainly developed by T. from the United States D. Williamson Company and UK based Stats Group have control (Figures 19, 20).However, these two companies mainly provide pipeline repair solutions in the form of technical services.

In this context, after years of research and development, China University of Petroleum (Beijing) has significantly narrowed the gap with the international advanced level, and some technical fields have reached the international leading level.In terms of pressure anchoring and sealing technology, the research team has innovatively proposed a sealing rubber cylinder structure with a large radial expansion ratio (Figure 21, 22), which not only enables the intelligent sealing device to have high passability when traveling inside the backup pipe, but also simplifies the hydraulic system structure, making it more suitable for pressure sealing operations with small diameters and high pressures inside the pipe.

In terms of communication technology both inside and outside the tube, optimizing coil size and layout has improved the receiving efficiency of ultra-low frequency signals.The research team independently developed key components such as signal processing and amplification circuits, and tested the communication system inside and outside the entire casing. The communication distance can reach more than 1.5 meters, providing technical support for intelligent maintenance of oil and gas pipelines.

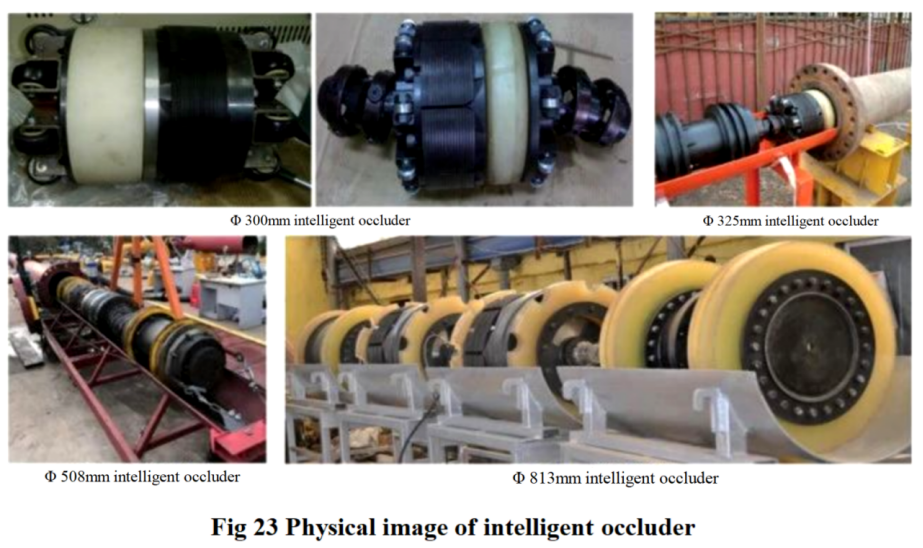

To solve the problem of secondary accidents that may occur after the failure of intelligent sealing devices for oil and gas pipelines, an innovative emergency unsealing technology based on pure hydraulic drive is proposed, and the technology is verified through a combination of hydraulic system simulation and experiment.In addition, China University of Petroleum (Beijing), in collaboration with Sinopec Dalian Petrochemical Research Institute, China Petroleum Pipeline Engineering Co., Ltd. Maintenance and Repair Branch, and other companies, has successfully completed the development of various diameter pipeline intelligent plug prototypes, including specifications such as Φ 300 mm, Φ 325 mm, Φ 508 mm, and Φ 813 mm (Figure 23), covering the application needs of various pipe diameters.

3. Summary and Prospect

3.1 Summary

This article proposes technical requirements for different emergency scenarios, with a focus on the research progress of new technological equipment such as remote control, rapid cold stripping, and non stripping anti-corrosion layer plugging. By introducing innovative emergency maintenance technology and equipment outside the pipeline, such as remote control excavation technology, rapid cold peeling anti-corrosion layer technology, and non peeling anti-corrosion layer rapid plugging technology, efficient plugging and repair can be achieved, greatly improving the efficiency and safety of emergency response.In addition, breakthroughs have been made in the research of emergency sealing technology inside the pipeline, especially in the field of high-pressure intelligent sealing technology inside the pipeline, which can better adapt to the operational needs in high-pressure and high-risk environments.

3.2 Outlook

(1). By establishing complex resource allocation and scheduling models, using mathematical methods to describe the uncertainty of material demand, scheduling time, and accident location in the process of emergency material allocation and scheduling, scientific emergency resource allocation and scheduling plans can be formulated to improve the efficiency and accuracy of emergency response.

(2). By utilizing digital twin technology to simulate the development trend of emergency response to pipeline leaks, providing predictive and preventive emergency response methods, optimizing emergency plans, and providing scientific decision-making support for emergency response to oil and gas pipeline leaks in real environments, we ensure more efficient and reliable emergency response.

(3). Knowledge graph technology supports the rapid generation of emergency response plans, 3D model visualization technology enables the rapid acquisition of key emergency information, and VR/AR technology provides unmanned precision remote control operation capabilities, comprehensively improving the intelligence level of emergency response.