Research on Key Technologies and Equipment for Emergency Response to Oil and Gas Pipeline Leakage(Part 1)

Abstract

The total length of China's long-distance oil and gas pipelines has exceeded 180000 kilometers, of which pipelines that have been in operation for over 20 years account for about 20% -30% of the total.With the influence of factors such as aging and corrosion of pipelines, the risk of pipeline leakage is increasing day by day.In addition to natural aging, external factors such as weld failure, geological disasters, and third-party damage also increase the risk of leakage.The geographical environment traversed by long-distance oil and gas pipelines is complex and varied, including mountains, tunnels, water networks, as well as complex crossing areas and goafs.These geographical conditions pose significant challenges for pipeline accidents, especially in emergency response and repair processes.Currently, existing leak emergency response technologies and equipment exhibit insufficient applicability when facing these complex scenarios, and emergency technologies and equipment for some key scenarios are still in a blank state, requiring further research and development.This article summarizes the leakage risks and causes of long-distance oil and gas pipelines in China, analyzes the difficulties in emergency response in complex geographical environments, and points out the shortcomings of existing technologies.Based on this, technical requirements for different emergency scenarios were proposed, and the development direction of future emergency response equipment was discussed.By strengthening cooperation and technological innovation in multiple fields, promoting the improvement of emergency response technology and the upgrading of equipment, and improving the efficiency of accident emergency response, we ensure energy security and social stability.

According to statistics, about 60% of China's in-service oil and gas pipelines have been in service for more than 10 years. Due to long-term service, these aging pipelines can suffer from pipeline defects caused by factors such as corrosion, external interference, and crustal migration, resulting in pipeline failure.Therefore, in recent years, with the prominent aging problem of pipelines, China's oil and gas pipelines have gradually entered a high-risk period of accidents. These accidents not only cause economic losses, but also pose a threat to the environment and personnel.Taking the oil pipeline explosion accident that occurred in Qingdao in 2013 as an example, the pipeline involved in the accident was built and put into use in July 1986, and has been in operation for 27 years.Due to the long service life of the pipeline, corrosion and perforation occurred, resulting in crude oil leakage and explosion, causing a major safety production accident with 62 deaths and 136 injuries.The safety issues of oil and gas pipelines have received unprecedented attention, and correspondingly, higher requirements have been put forward for the safe operation of in-service pipelines.The emergency maintenance and repair technology and equipment for pipelines, as an important part of ensuring the safety of pipeline operation, have received increasing attention and research. Through timely and efficient emergency response, the risk and impact of pipeline accidents can be effectively reduced, and the stability and safety of oil and gas transportation systems can be improved.

1. Research Progress on Emergency Maintenance and Repair Technology and Equipment Outside the Jurisdiction

1.1 Remote Excavation Technology and Equipment for Emergency Maintenance and Repair of Oil and Gas Pipelines

The leakage area of oil and gas pipelines usually forms a highly flammable and explosive high-risk environment, and the potential risks of traditional manual excavation methods are significant. Developing remote controlled excavation devices has become an important direction to improve the safety and efficiency of emergency rescue.From the current research status abroad, relevant technologies have gradually matured.The research focuses mainly on the intelligence and precision of remote control equipment, including the automation operation of hydraulic excavation devices, the application of force feedback technology, and the construction of innovative control frameworks.These research results have shown significant value in improving operational safety, response efficiency, and equipment stability.Research in this field started relatively late in China, but has developed rapidly in recent years. The research work mainly focuses on the technical research and development of oil and gas pipeline emergency needs, covering multiple aspects such as explosion-proof design, noise control, remote monitoring and control, forming a relatively systematic application technology system.Significant progress has been made in environmental adaptability and control accuracy through the exploration of intelligent perception technology and algorithm optimization.

Supported by the National Key R&D Program, China University of Petroleum (Beijing), in collaboration with Shanhe Intelligent Special Equipment Co., Ltd. and other enterprises, is conducting research on remote control explosion-proof excavation technology and equipment.By combining advanced positioning systems and precise robotic arm control technology, automated and precise excavation can be achieved through remote control.Specifically, the operational positioning accuracy of the device is better than 50mm, ensuring that the robotic arm can accurately locate excavation work around the leakage point in complex terrain and efficiently carry out excavation operations. In addition, the excavation efficiency of this equipment can reach over 20m3/h, significantly improving the efficiency of emergency repairs.

1.2 Rapid Cold Stripping Technology and Equipment for Anti corrosion Coating of Oil and Gas Pipelines

At present, the peeling of pipeline anti-corrosion coatings in the domestic and foreign industrial sectors is usually combined with heating peeling, but it has obvious limitations. Not only is the peeling speed slow, which affects the efficiency of emergency repairs, but the high-temperature heating process also causes thermal damage to the surrounding intact anti-corrosion coatings, weakening their anti-corrosion performance (Figure 1, 2).In complex and high standard pipeline emergency maintenance scenarios, these issues further increase the difficulty of pipeline repair work.

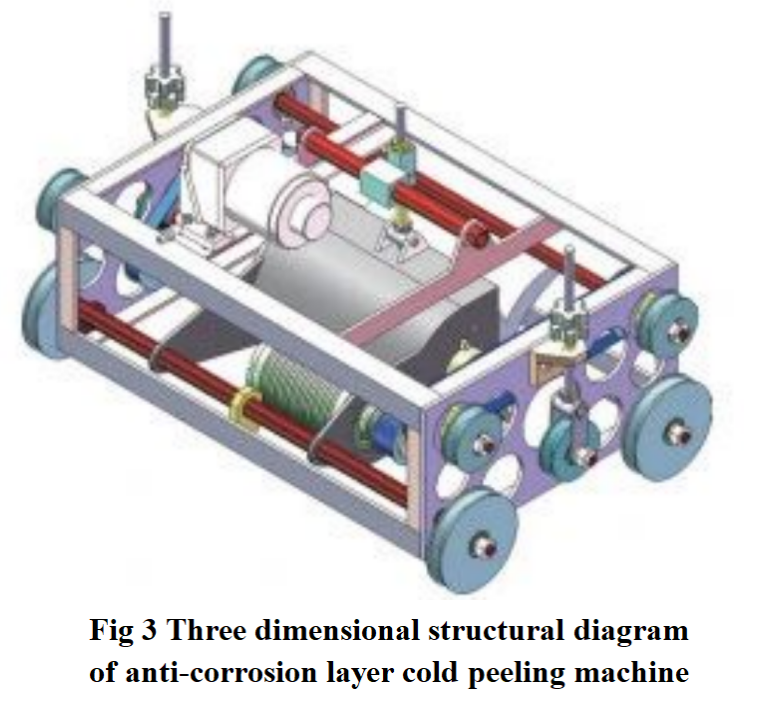

To solve the above problems, China University of Petroleum (Beijing) has developed a rapid cold stripping technology for pipeline external anti-corrosion coating.This technology does not rely on heating methods, but achieves efficient peeling of the anti-corrosion layer through cold peeling, ensuring operational safety and ease of operation.The cold peeling machine adopts the principle of flexible cutting tools, which will not cause any damage to the wall of the pipeline itself during the peeling process, effectively protecting the structural integrity of the pipeline wall.This non heating peeling technology ensures rapid peeling of the anti-corrosion layer without affecting the protective performance of the surrounding anti-corrosion layer (Figure 3).At the same time, the cold peeling machine has strong peeling ability, with a peeling power of 2kW, a peeling speed of up to 200mm/min, and a cutting width of over 150mm.Taking a pipeline with a diameter of 1016mm as an example, the cold peeling machine only takes 15 minutes to complete one week of cutting, greatly improving the efficiency of pipeline anti-corrosion layer peeling (Figure 4).In addition, the device is designed to be flexible and can be quickly installed and disassembled. The entire operation process only requires 2 operators, further simplifying the on-site operation process.

1.3 Rapid Leak Sealing Technology and Equipment for Oil and Gas Pipelines without Peeling off the Anti-corrosion Layer

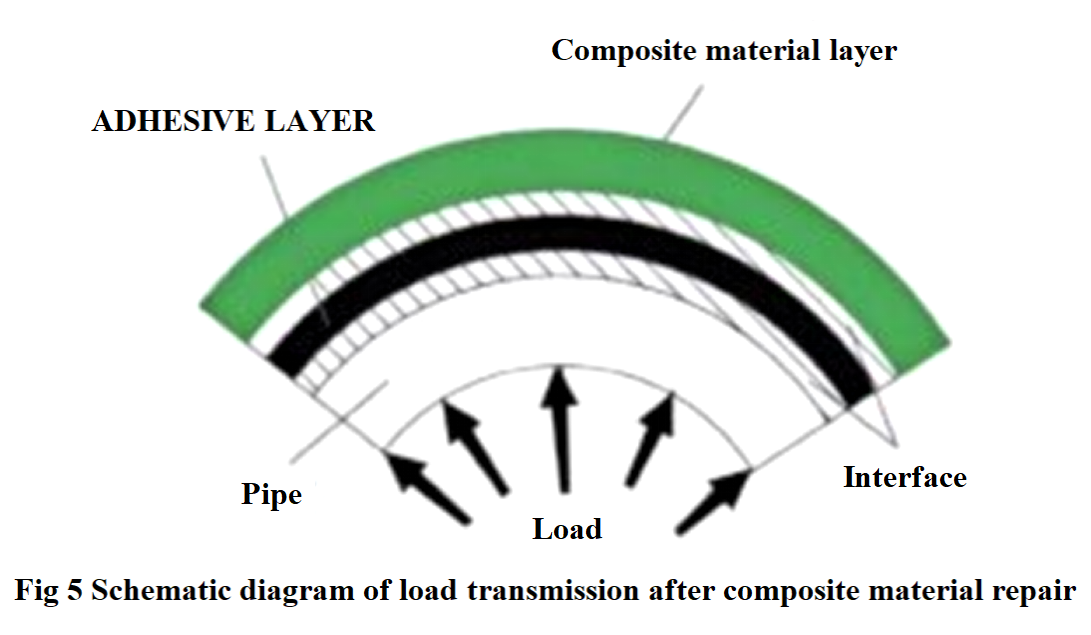

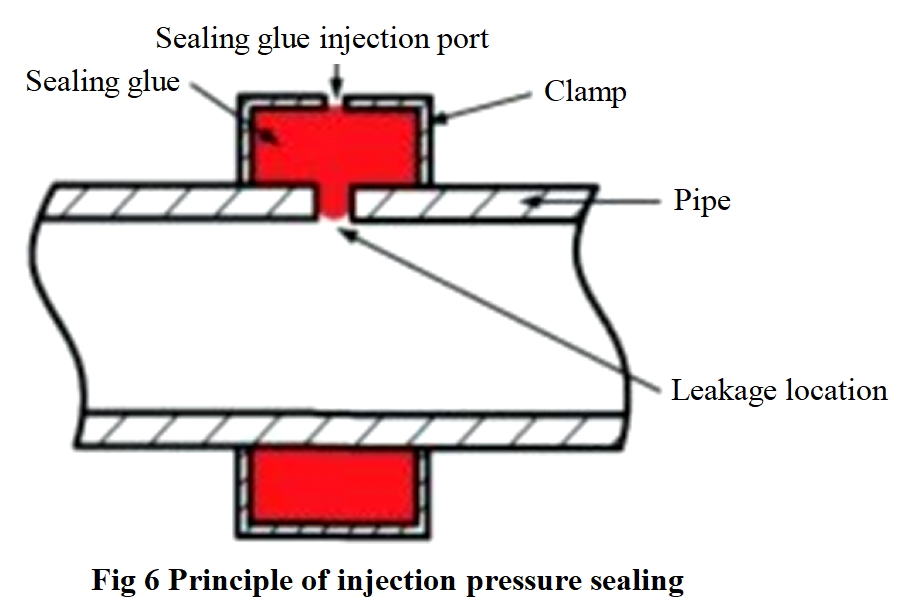

During the operation of oil and gas pipelines, radial deformation and damage often occur due to external forces and geological activities, leading to leakage problems.To solve this problem, commonly used leak sealing techniques include composite material repair, injection pressure sealing, and mechanical clamp sealing (Figure 5-8).

Research abroad mainly focuses on comparing the performance of different plugging technologies and developing efficient plugging devices suitable for various environments and occasions. However, domestic research focuses more on analyzing the limitations of existing plugging technologies, optimizing design for problems, and striving to develop plugging instruments with simpler structures, more convenient operations, and higher efficiency. This research direction has effectively promoted the application and development of leak sealing technology in complex working conditions.