Research and application status of temperature resistance polyacrylamide drag reducers(Part 2)

2.2 Hydrophobic Monomer Copolymerization

AM can be copolymerized with hydrophobic monomers to prepare hydrophobic associated polyacrylamide (HAPAM), which involves grafting a certain proportion of hydrophobic groups onto the main chain of PAM molecules, making them amphiphilic molecules. The hydrophobic groups on the HAPAM molecular chain form intramolecular or intermolecular association structures due to repulsive interactions with water molecules. Hydrophobic association is an endothermic process, and heating is beneficial for intermolecular association. Hydrophobic association enhances the thermal stability of HAPAM molecules. The commonly used PAM hydrophobic modified monomers are AM derivatives, acrylic esters, styrene and its derivatives, and ionic hydrophobic monomers.

2.2.1 AM derivatives

The hydrophobic groups in this type of HAPAM molecular chain are connected to the main chain through amido groups, and hydrogen bonds can be formed between amido groups, amido groups, and water molecules. The copolymer has good water solubility and is easy to form intramolecular associations. The drag reduction effect may decrease due to the curling of the molecular chain. The most commonly used AM derivative hydrophobic monomer is N-alkylacrylamide. McCormick et al. found that the viscosity of N-n-decylacrylamide/AM copolymer solution increases with increasing temperature. But the amide group undergoes hydrolysis around 80 ℃, causing the hydrophobic group to fall off and the hydrophobic association structure to be destroyed.

2.2.2 Acrylates

The hydrophobic groups in this type of HAPAM molecular chain are connected to the main chain through ester groups, and commonly used acrylic ester based hydrophobic monomers are alkyl acrylate, fluorinated acrylate, etc. The hydrolysis temperature of ester groups in alkyl acrylate is lower than that of amide groups; Fluorinated acrylate has good thermal stability, but it can also undergo hydrolysis at high temperatures, causing the detachment of hydrophobic groups, and the cost is high.

2.2.3 Styrene and its derivatives

To solve the problem of high-temperature hydrolysis of AM derivatives and acrylic esters, styrene and its derivatives are selected as hydrophobic monomers to copolymerize with AM. The hydrophobic groups of the copolymer are directly connected to the main chain of HAPAM molecules, which is easy to form intermolecular associations and has good thermal stability.

2.2.4 Ionic hydrophobic monomers

Ionic hydrophobic monomers contain both hydrophobic and ionic groups (anions and cations), which not only enhance the solubility of HAPAM in water, but also inhibit intramolecular association through electrostatic repulsion, leading to molecular chain extension and increasing fluid mechanical volume. The commonly used ionic hydrophobic monomers are long-chain quaternary ammonium salt monomers (such as octadecyldimethylallyl ammonium chloride).

HAPAM generally contains multiple hydrophobic groups, and its association performance improves with the increase of hydrophobic group content and chain length, but its water solubility also decreases. Therefore, the content of hydrophobic groups is usually less than 2% (x), and the carbon number of hydrophobic chains is usually between 6 and 8; Intramolecular association is not conducive to molecular chain extension, resulting in a decrease in drag reduction effect. Hydrophobic monomers that can inhibit intramolecular association are preferred; As the temperature continues to rise, the thermal motion of molecular chains and hydrophobic groups intensifies, and the hydrophobic association weakens. The research results indicate that hydrophobic modification has limited effect on the temperature resistance of PAM drag reducing agents.

Hydrophobic association PAM drag reducing agent can also improve the sand carrying capacity of smooth hydraulic fracturing fluid. The closure stress of deep reservoir strata is high, and higher concentrations of proppant need to be injected to achieve effective support for the fracture network. By adjusting the concentration of drag reducing agent to regulate the viscosity of the fracturing fluid, variable viscosity drag reducing agent technology has gradually formed. This technology not only retains good drag reducing effect, but also solves the problem of poor sand carrying capacity of smooth hydraulic fracturing fluid, meeting the construction requirements of forced sand fracturing and reducing the application cost of fracturing fluid.

2.3 Inorganic Nano/PAM Composite Drag Reducing Agent

Inorganic nanomaterials and PAM can form high-performance inorganic nano/PAM composites through physical adsorption, hydrogen bonding, and covalent bonding, which have improved temperature resistance, shear resistance, salt resistance, and other properties. They have been widely used in drilling, fracturing, and enhanced oil recovery.

The synthesis methods of inorganic nano/PAM composite drag reducing agents mainly include:

1) . Blending method. Inorganic nanoparticles are uniformly dispersed in PAM through mechanical stirring and other methods. The inorganic nanoparticles are combined with PAM molecular chains through physical adsorption, hydrogen bonding, etc. The operation is simple, but the nanoparticles are prone to aggregation;

2) . Copolymerization method. By surface modification of inorganic nanoparticles and grafting copolymerization with monomers such as AM, covalent and ionic bonds can be formed between inorganic nanoparticles and PAM molecular chains, further enhancing the thermal stability of PAM compared to the blending method.

The most studied inorganic nanomaterial is nano SiO2. Cao et al. conducted a comparative study on the thermal stability of AM/AMPS copolymer, AM/AMPS/nano SiO2 copolymer, and AM/AMPS/aminated nano SiO2 copolymer. They found that the hydrolysis degrees of the three copolymers were about 50%, 40%, and 25% after aging in an aqueous solution at 140℃ for 12 hours, and the hydrodynamic radius decreased by about 50%, 25%, and 5%, respectively. The experimental results indicate that the thermal stability of the AM/AMPS/aminated nano SiO2 copolymer molecular chain is the best; The aminated nano SiO2 and PAM molecular chains in AM/AMPS/aminated nano SiO2 copolymers are simultaneously connected in three forms: hydrogen bond, ion bond, and covalent bond, which is more stable than the structure of AM/AMPS/nano SiO2 copolymers. However, many studies on inorganic nano/PAM composites have shown that the specific surface area and strength effects of inorganic nanoparticles can easily lead to particle aggregation. This problem needs to be addressed during the preparation process in order to obtain stable and dispersed composite materials for industrial applications.

3. Application Status of 3 Temperature Resistant PAM Drag Reducing Agents

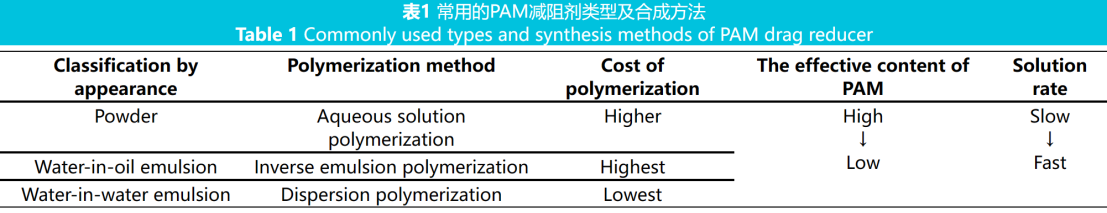

PAM drag reducer can be divided into powder type, water in oil lotion type and water in water lotion type according to its appearance. See Table 1 for main characteristics.

The powder drag reducer has the advantages of convenient long-distance transportation and long-term storage, and is more stable than lotion drag reducer; Lotion friction reducer has faster dissolution than powder friction reducer, which is more suitable for continuous mixed fracturing operations, and even can realize direct mixing without configuration, simplifying the fracturing pumping process and reducing the construction cost.

The AM/SSS copolymer drag reducing agent synthesized by Wang Wenzhe et al. achieved a viscosity of 2.48 MPa · s after shearing at a shear rate of 170 s-1 for 1 hour in high salinity water at 140 ℃. The AM/SSS drag reducing rate of 0.1% (w) can reach 67.2%. Yao Yiming et al. prepared a high-temperature resistant drag reducing agent using AM, acrylic acid (AA), cationic monomers, and P-type rigid group unsaturated monomers, and applied it in key lateral drilling horizontal wells of Dingshan Structure B. The vertical depth of the formation was 4095.46 meters, the horizontal section length was 1234.00 meters, the formation temperature was 143℃, and the on-site drag reducing rate reached 78.0%. Gao Qingchun et al. synthesized AM/NVP/ACMO/AMPS copolymer drag reducing agent, with a drag reduction rate of 71.9% at 140℃ using 0.1% (w) AM/NVP/ACMO/AMPS. The agent was applied on-site in the THXX well of the Yingshan Formation, with a depth of 6156.05-6249.00 m and a formation temperature of 140℃. The on-site implementation effect was good.

Variable viscosity drag reducing agents have been widely used in the fracturing of tight shale oil and gas reservoirs. Ibrahim et al. synthesized a variable viscosity drag reducing agent FR1 using AM, AA, and hydrophobic monomer Z as monomers. The drag reducing rate was higher than 70% in both clean water and saline water, and the viscosity of FR1 at 0.3%(φ) could reach 15 MPa·s. Jia Jinya et al. prepared a hydrophobically associating viscosity reducing agent AM/DMC/MEDDDAB using AM, methacryloyloxyethyltrimethylammonium chloride (DMC), and methacryloyloxyethyldodecyldimethylammonium bromide (MEDDAB) as monomers. The viscosity of 0.1% (w)AM/DMC/MEDDDAB reached 10 MPa·s and the drag reduction rate was 65.74%. Zhao et al. proposed a high viscosity polymer drag reducing agent HVFR, which has been applied on-site in Montney, Canada. Compared with conventional slippery water, viscous slippery water not only has good drag reduction effect, but also has good sand carrying capacity.

The research and application of inorganic nano/PAM composite drag reducing agents are less than those of AM temperature resistant copolymerization drag reducing agents. Yu Weichu et al. developed JHFR-2 type green and clean nanocomposite high-efficiency liquid drag reducer, with a drag reduction rate of 70.2% after aging at 130℃ for 8 hours.

There are many synthesis and applications of temperature resistant PAM drag reducing agents, mainly by introducing large side groups, rigid side groups, hydrophobic groups, and combining them with nanocomposites. By fully utilizing the advantages of each method, the contradiction between temperature resistance and drag reducing effect can be solved, which can meet the construction needs of deep shale gas sliding water fracturing.

4. Conclusion

PAM drag reducing agent is the core additive of smooth hydraulic fracturing fluid. PAM molecular chains are prone to thermal oxidative degradation and fracture under high temperature conditions, resulting in a significant decrease in drag reducing effect. The temperature resistance of PAM drag reducing agents can be improved through three methods: copolymerization with temperature resistant monomers, copolymerization with hydrophobic monomers, and synthesis of inorganic nano/PAM composite drag reducing agents. However, the temperature resistance during on-site application is only one of the important properties of drag reducing agents, especially in the development of deep shale gas and other reservoirs, the following research needs to be carried out.

During the smooth water fracturing process, a large amount of fracturing fluid is injected into the formation. PAM drag reducing agent is a high molecular weight polymer that can easily adsorb on the rock surface and block microcracks and pore throats, leading to a decrease in single well productivity. A biodegradable drag reducing agent should be developed, which is synthesized by copolymerizing AM with degradable monomers under certain conditions (time, temperature, etc.) to obtain a molecular chain composed of degradable and non degradable parts, achieving self degradation of the drag reducing agent in the formation and reducing the degree of damage caused by the drag reducing agent to the formation.

As the temperature resistance of PAM type drag reducing agents increases, the flexibility of the drag reducing agent molecules also decreases, resulting in a decrease in drag reducing effect. As the reservoir temperature increases, this contradiction becomes more prominent. How to solve the contradiction between temperature resistance and drag reduction performance will be one of the important directions in the research of PAM drag reducing agents.

In the process of oil and gas exploration and development, scientific and effective environmental protection measures must be taken. During the research and development of drag reducing agents, non-toxic and environmentally friendly synthetic materials must be selected, and green and economical synthesis routes and processes must be optimized to minimize the adverse effects of drag reducing agents on the environment.