Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.1.3 Metal based Leak Sealing Materials

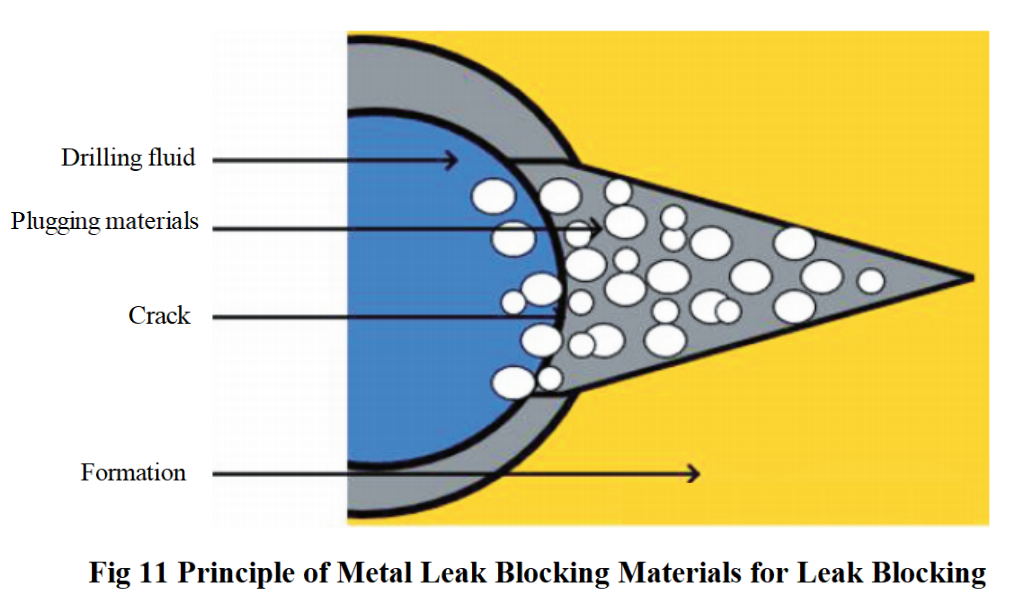

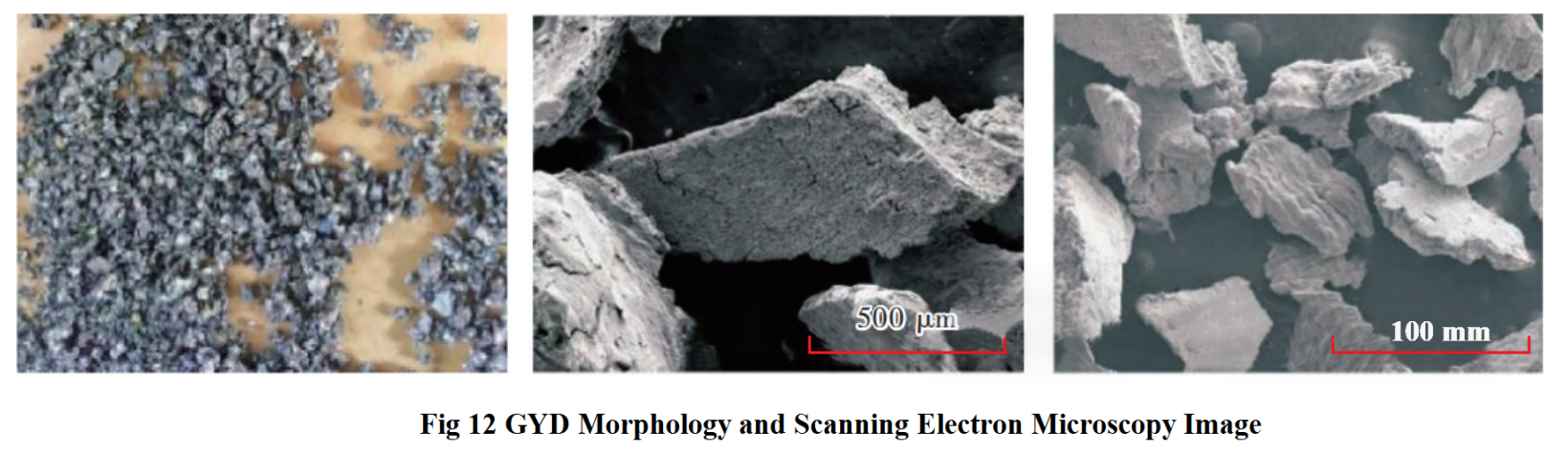

Metal plugging materials are plugging materials composed of high-strength metals, fiber materials, high-temperature binders, etc., including metal particles such as aluminum, iron, zinc, etc. These metal particles react with water or drilling fluid in the wellbore liquid environment, and the gas or solid products produced by the reaction form bubbles or solid plugging layers at the leakage point, physically preventing the penetration of liquid and effectively addressing the problem of wellbore leakage.Aluminum powder reacts with water to produce hydrogen gas, while iron powder reacts with water to produce hydrogen gas and ferrous hydroxide. The principle is shown in Figure 11.For bottom hole leakage in aqueous environments, metal based plugging materials can provide a certain sealing effect and are suitable for leakage situations with large cracks, pores, or other leakage channels.Metal plugging materials are commonly used for lost circulation in high temperature, high pressure and corrosive environments. In order to meet a series of requirements for plugging materials in terms of oil dispersion, high rigidity and high acid solubility, Ai Zhengqing and others introduced GYD plugging materials, which are made of foam aluminum alloy materials, with pressure bearing strength up to 25 MPa, acid solubility up to 65%, good stability, and appearance as shown in Figure 12.

2.2 Conventional Plugging Materials

Conventional leak sealing materials are commonly referred to as LCMs (Lost Circulation Materials), which include synthetic graphite, calcium carbonate, walnut shells, mica sheets, asphalt, and fibers. They mainly solve the problem of leakage through physical methods such as filling and plugging. Conventional plugging materials can be divided into particle plugging materials and fiber plugging materials according to their physical state, usage method, and plugging effect.

2.2.1 Particle LCMs Plugging Material

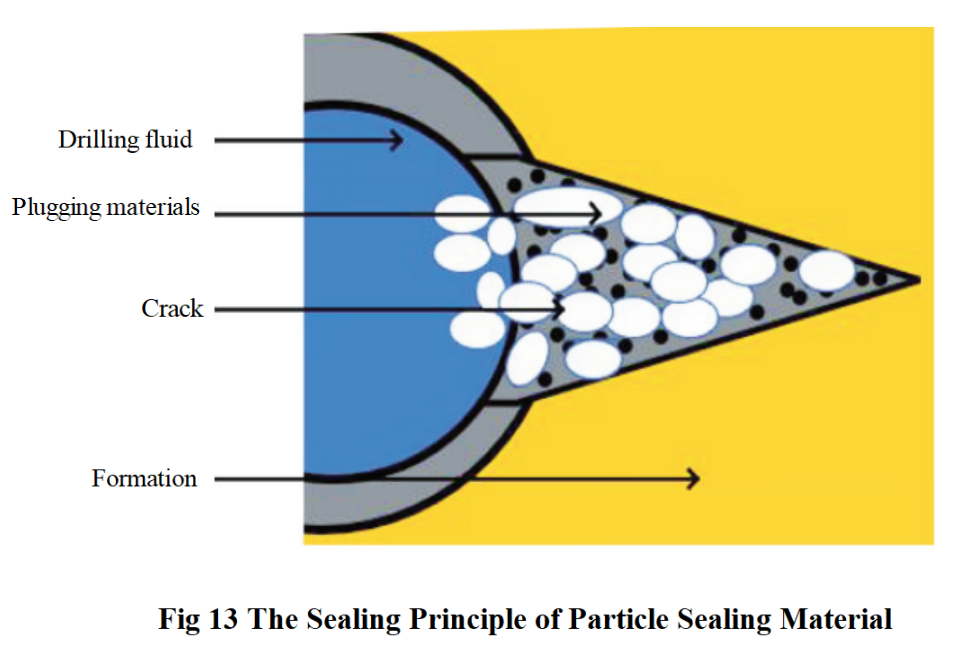

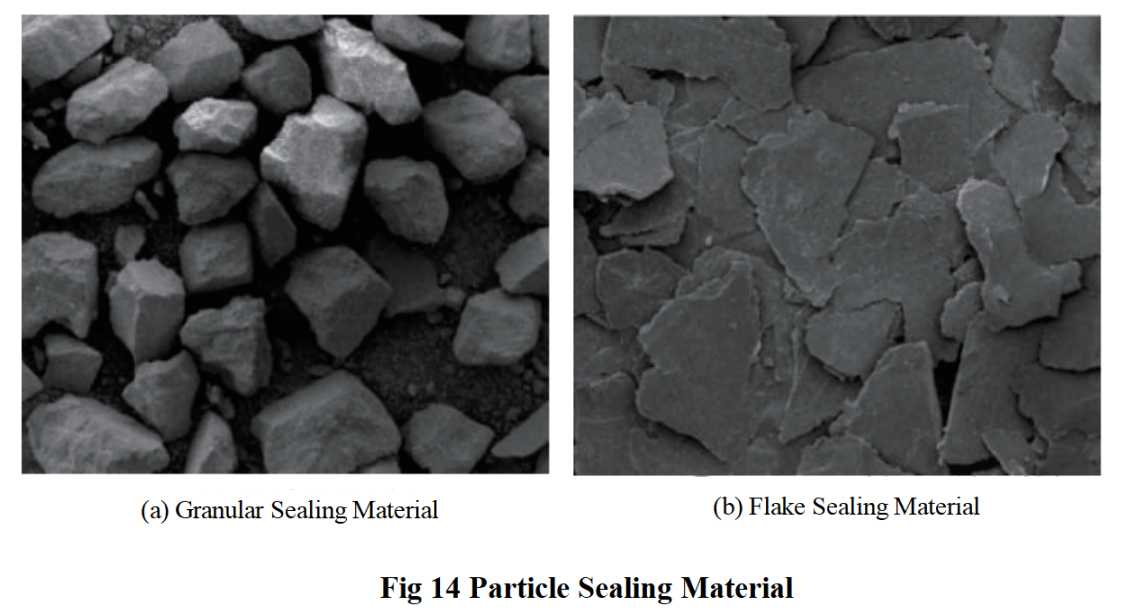

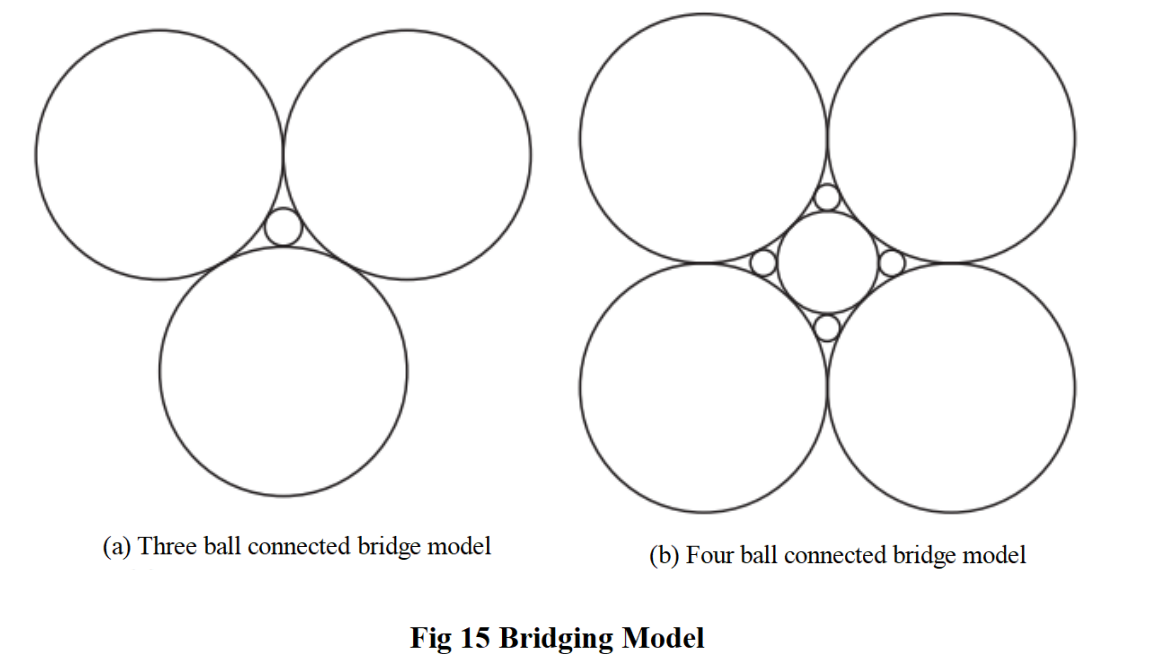

Particle plugging materials are usually mixed at the drilling site and then pumped to the underground leakage layer to seal the plugging channel.If the particle plugging material meets the requirements of forming effective bridging and plugging, once it enters the leakage channel, it can quickly form a plugging zone under filtration, as shown in Figure 13.The combination of particles (including granular and sheet-like, as shown in Figure 14) and fibers for leak sealing is also quite common. Foreign scholars have also proposed the bridging model theory of three particle interface and four particle interface (Figure 15), where the spheres in the model represent particles, and the particle size of the particle plugging material is usually 250-600μm. Some nanoscale particle plugging materials have also been developed, such as common nano silica, nano iron hydroxide, and nano barium sulfate.Based on experimental tests and field experiments conducted by foreign scholars, it has been found that particle plugging materials with a wide range of particle sizes have better plugging effects than single specification particle plugging materials. Ghazali et al. studied the influence of particle size and concentration of oil palm empty fruit granules (OPEFB) in water-based mud (WBM) on LCMs plugging materials, once again verifying that particle size has a significant impact on the effectiveness of plugging.

2.2.2 Fiber based Sealing Materials

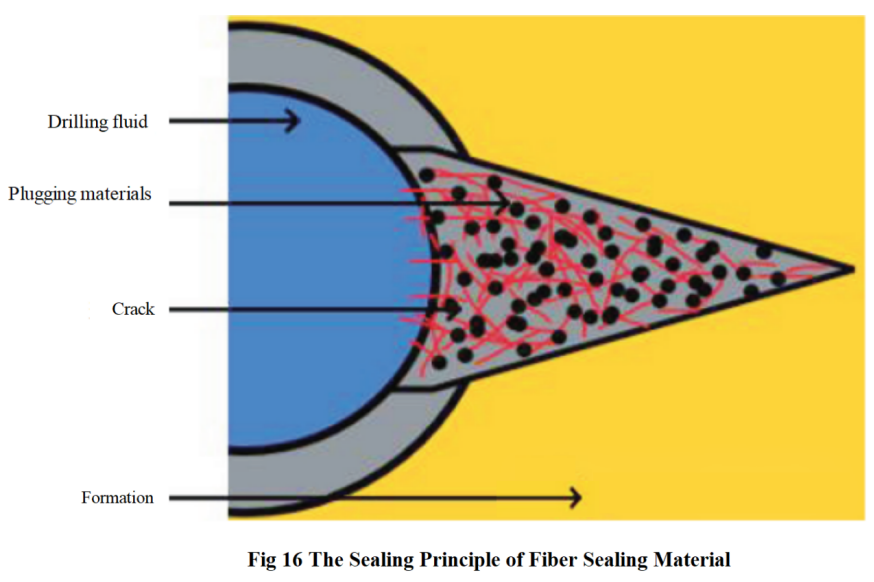

The plugging principle of fiber plugging materials is mainly to use their fibrous structure and chemical properties to fill, bond, and expand, thereby achieving the purpose of plugging. The plugging process of fiber materials is shown in Figure 16.Many materials can be used to prepare fiber materials (including cellulose, nylon, polypropylene, shredded paper, etc.), and acid soluble fibers have been applied in leak sealing. Liu Rui et al. formed mineral fiber materials through electric heating or mass proportioning.The fiber concentration in the drilling fluid is sufficient to form a network structure. If the fiber concentration is too high, it may cause an increase in the viscosity of the drilling fluid, thereby affecting its pumping performance.When fiber sealing material enters a leak or crack in a pipeline or container, it quickly absorbs the surrounding liquid, forming a gel like substance with high viscosity and strong adhesion to block the leak or crack and achieve the purpose of sealing.

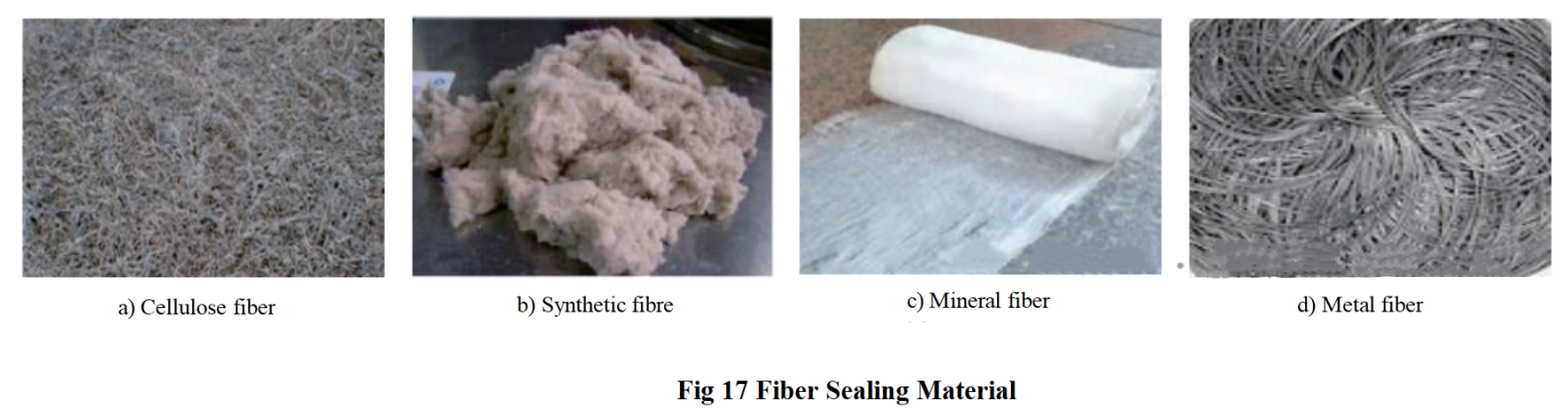

There are currently four most common types of fiber plugging materials in the oil and gas industry.

1) Cellulose fibers. Cellulose fibers are made from wood pulp and are the most commonly used type of fiber based drilling material. They are widely used in leakage control, wellbore reinforcement, and filtration control, as shown in Figure 17 (a).

2) Synthetic fibers. Synthetic fibers are made of materials such as nylon, polyester, or polypropylene. Polypropylene fibers are usually made from polypropylene slices through spinning and stretching processes, and have excellent high-temperature resistance, acid and alkali resistance, and high tensile strength. They are commonly used in leakage situations with high wellbore temperatures. Some scholars add polyester fibers to asphalt concrete to improve its flexibility, high-temperature resistance, and fatigue resistance, and enhance its comprehensive performance. Synthetic fibers are commonly used for leakage control and wellbore reinforcement, as shown in Figure 17 (b).

3) Mineral fibers. Mineral fibers are made of materials such as glass fibers or basalt, characterized by high strength and chemical stability. They are inorganic non-metallic materials with extremely high elastic modulus, tensile strength, and bending strength. However, they have the disadvantages of being brittle and not wear-resistant, as shown in Figure 17 (c).

4) Metal fibers. Metal fibers made of materials such as steel, aluminum, or copper are commonly used to solve leakage problems that traditional leak sealing materials cannot cope with, such as oil phase dispersion, acid solubility, and high pressure, as shown in Figure 17 (d).

2.3 Solidifiable and LCMs mixed Plugging Materials

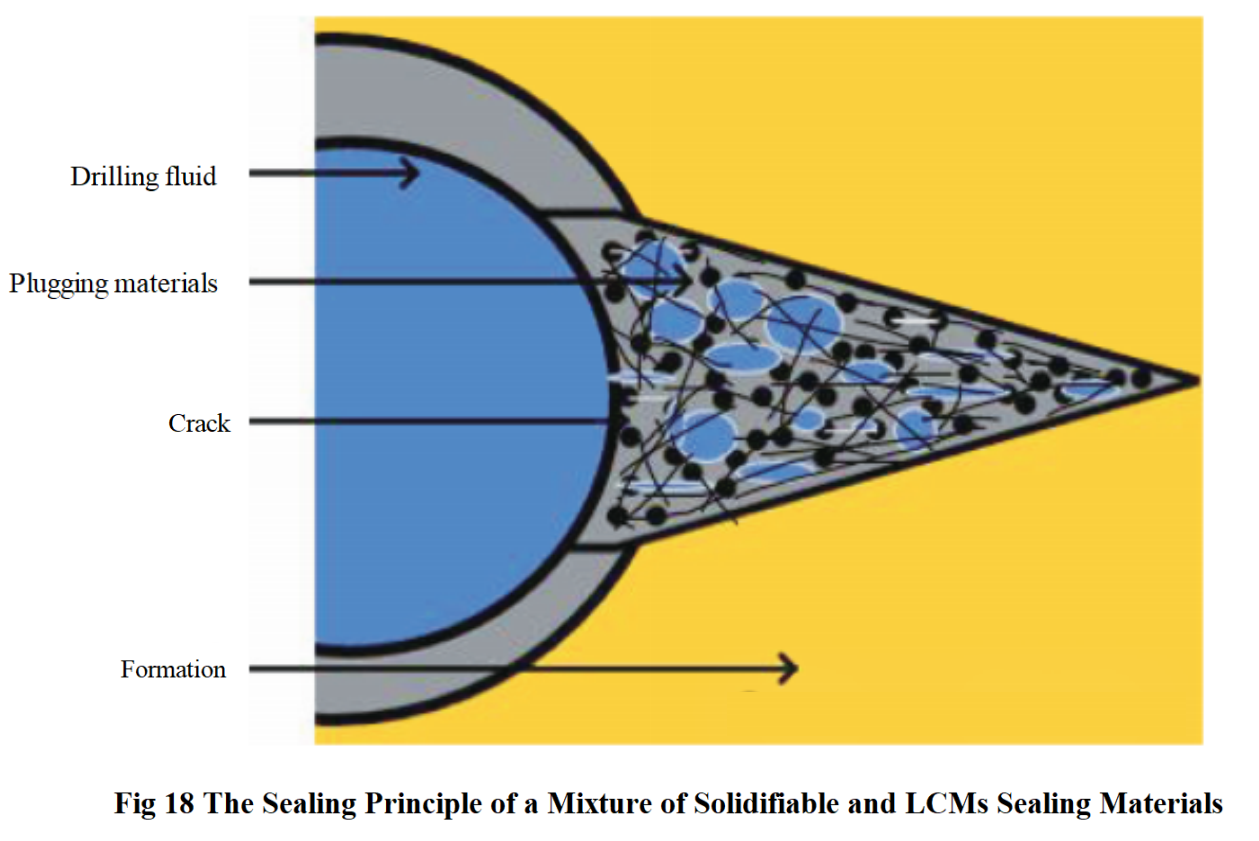

The solidifiable and LCMs mixed plugging material not only has the curing characteristics of solidifiable plugging materials, but also has the characteristics of better filling and plugging of granular plugging materials. This mixed plugging material forms a solid gel through hydration reaction, and at the same time, small granular components fill the leakage channel to achieve dual plugging effect (Figure 18). It is an effective mixed plugging material.

In drilling operation, the common combination of solidified and LCMs mixture plugging materials is gel and LCMs mixture. The gel and LCMs mixed plugging materials generally mix gel and LCMs in a certain proportion to form a gelled mixture in the drilling fluid. This gelled mixture is pumped into the leakage channel during the drilling process to form a blockage by solidification or cementation, so as to control the leakage.In the process of plugging, Caughro et al. emphasized the importance of gradually reducing the pump speed at the end of injection. This type of mixed system has been successfully applied to induce fracture type leakage in deep water wells in the Gulf of Mexico. In addition, this mixed system has become an important system for dealing with shale formation backflow (without drilling fluid returning to the wellhead).This mixed system plugging material can also be mixed with freshwater, saltwater, or seawater, and can also be used together with drilling fluids, oil-based drilling fluids, or synthetic based drilling fluids. It is worth mentioning that Ali et al. achieved successful plugging in multiple severely depleted and loose sandstone reservoirs using a mixture of solidifiable and LCMs plugging materials.

3. Application Effect of Sealing Materials

This article combines relevant literature from domestic and foreign sources over the past decade, and based on the assumption that the wells in the literature do not overlap with each other, explores in detail the plugging effects of solidifiable plugging materials, conventional plugging materials, and solidifiable and LCMs mixed plugging materials on high permeability matrix type, cave type, natural fracture type, and induced fracture type plugging data from over 2000 wells worldwide.

3.1 Application Effect in high Permeability Matrix Leakage

High permeability matrix type leakage generally occurs in loose sandstone or shallow conglomerate. The large pores developed in the rock matrix give these reservoirs a high permeability (10-100D), which can lead to pore type leakage. Pore type leakage may also cause excessive erosion of the formation, leading to wellbore instability and other problems.The severity of pore type leakage can vary between leakage and irreversible leakage depending on the rock permeability and drilling fluid properties. For high permeability matrix leakage, the particle size of the sealing material must ensure that the pore throat can be effectively sealed. 90% of the particle size in the sealing material must be smaller than the mainstream pore throat size in order for the sealing material to effectively seal the sealing layer.

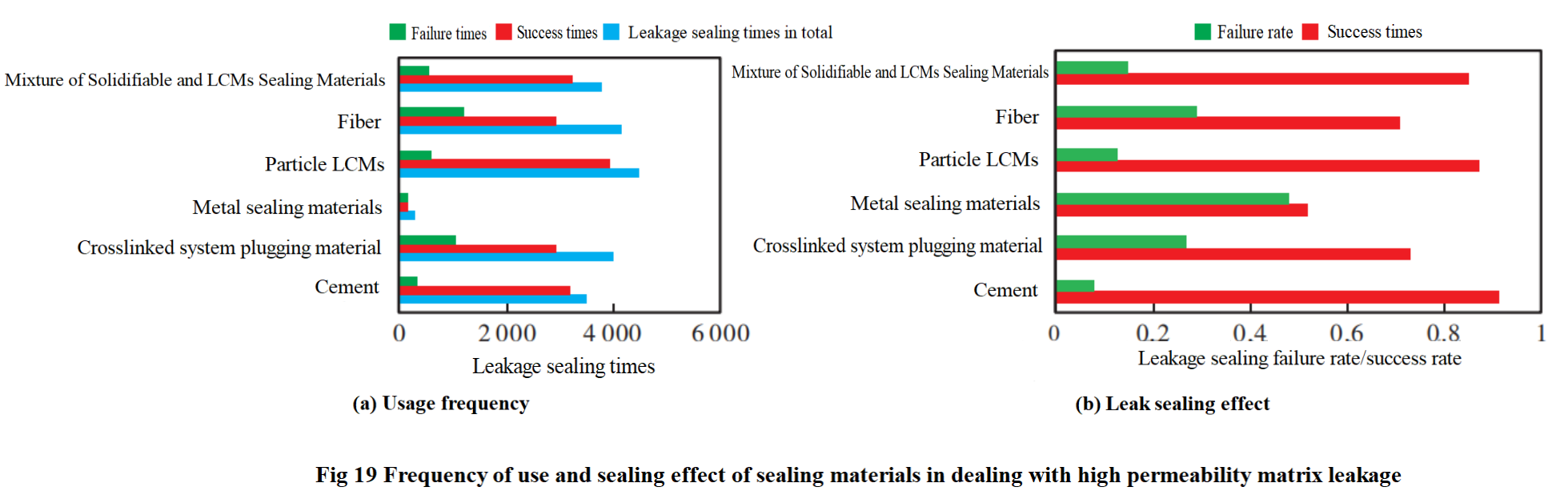

Through research on relevant literature at home and abroad in the past decade, it was found that the frequency of using plugging materials to control and eliminate high permeability matrix type leaks in drilling sites, from highest to lowest, is as follows: cement plugging materials, solidified and LCMs mixed plugging materials, granular LCMs plugging materials, cross-linked system plugging materials, fiber plugging materials, and metal plugging materials. Their success rates are 91%, 85%, 87%, 73%, 71%, and 52%, respectively. The specific statistical data is shown in Figure 19.Considering the success rate and cost of leak sealing, granular LCMs, solidifiable and LCMs mixed leak sealing materials are currently the most effective leak sealing materials for treating high permeability matrix type leaks.

3.2 Application Effect in Karst Cave Leakage

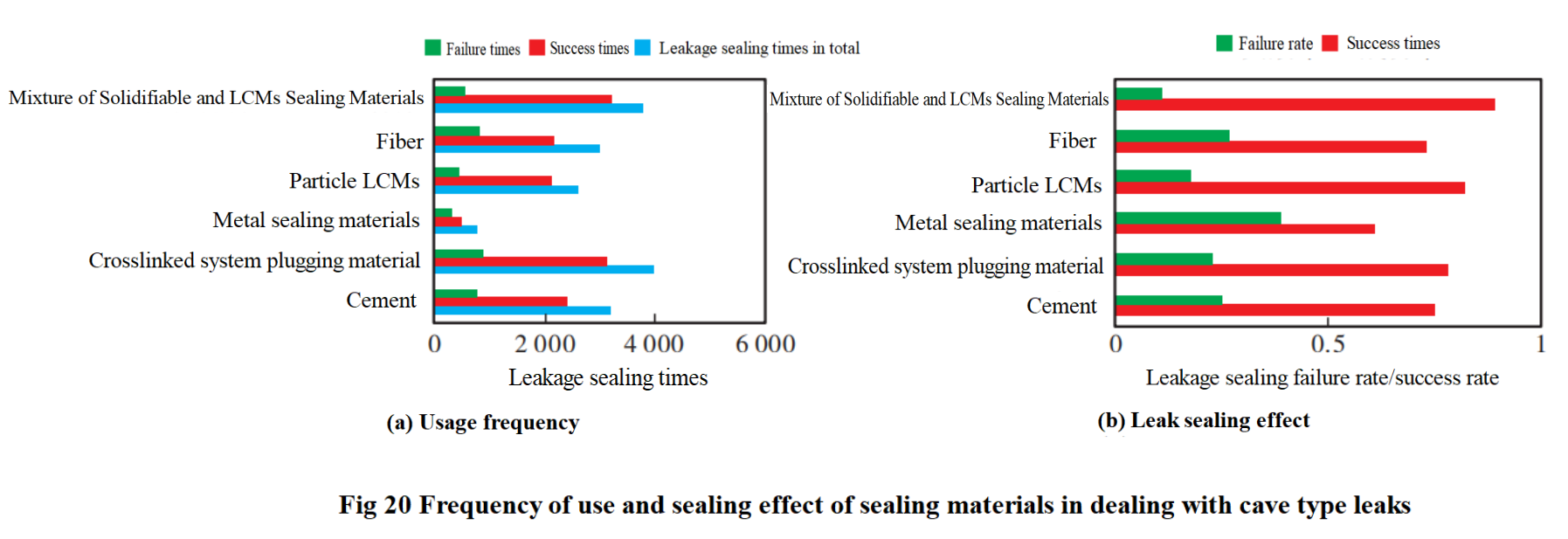

Cave type leakage is a relatively difficult problem to solve, and forced drilling may be one of the effective methods to solve it. However, a large amount of drilling fluid needs to be stored on the ground, and some special drilling methods can also be used, such as unbalanced drilling, casing drilling, and pressure mud cap drilling.Kumar et al. believe that adding fibers to plugging materials can help control the leakage of such formations; Secondly, the structural gel formed by cross-linked system plugging materials is used to plug the cavern type leakage, but this kind of material does not have acid solubility, and plugging with this kind of plugging material may lead to the production layer being unable to put into production.Through the investigation and statistics of relevant literature at home and abroad in the past decade, it was found that the frequency of using sealing materials to control and eliminate cave type leakage in drilling sites, from highest to lowest, is a mixture of solidifiable and LCMs, granular LCMs, cross-linked systems, cement, fiber, and metal sealing materials. Their sealing success rates are 89%, 82%, 78%, 75%, 73%, and 61%, respectively. The specific statistical data is shown in Figure 20.Considering the success rate and cost of leak sealing, granular LCMs and cement leak sealing materials are currently the most economical and practical leak sealing materials for treating cave type leaks.

3.3 Application Effect in Natural Crack type Leakage

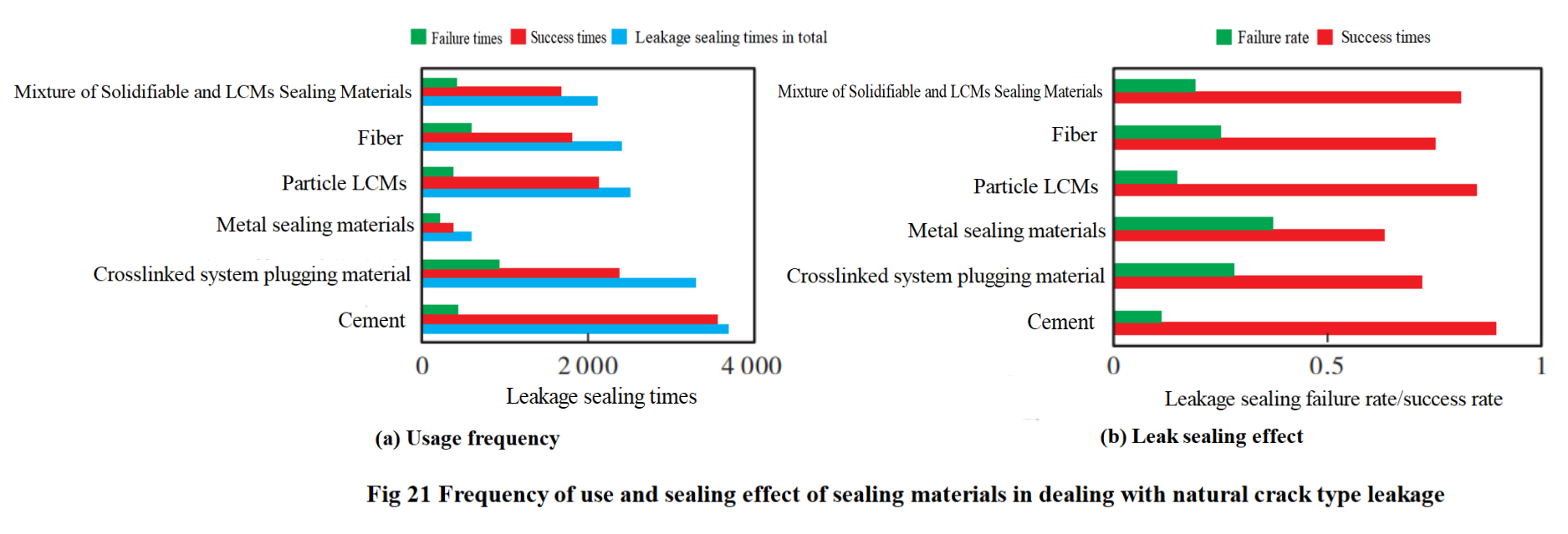

Natural fracture type leakage is more common in carbonate rocks, gas bearing shales, and geothermal wells. Wide natural fracture type leakage is often difficult to solve. The fracture grid developed in sedimentary rocks provides a high permeability leakage channel for drilling fluids. The biggest challenge is the inability to accurately determine the width of natural fractures. Unlike induced fracture type leakage, induced fractures can roughly estimate the width of fractures based on hydraulic fracturing research in the past decade. The hydraulic width of natural fractures depends on the orientation of fractures, the magnitude and direction of original geostress, and the mineralization characteristics in fractures.Lietard et al. suggest that in such formations, the use of plugging materials should be avoided, and more emphasis should be placed on controlling reservoir leakage through appropriate control of drilling fluid rheology, which is more conducive to reservoir protection than using plugging materials for plugging.Through research on relevant literature at home and abroad in the past decade, it was found that the frequency of using plugging materials to control and eliminate natural fracture type leakage in drilling sites was ranked from high to low as cement, granular LCMs, solidifiable and LCMs mixtures, fibers, cross-linked systems, and metal plugging materials. The success rates of plugging were 89%, 85%, 81%, 75%, 72%, and 63%, respectively. The specific statistical data are shown in Figure 21.Considering the success rate and cost of plugging, cement and fiber plugging materials are currently the most economical, practical, and effective plugging materials for natural crack type leaks.

3.4 Application Effect in Inducing Crack type Leakage

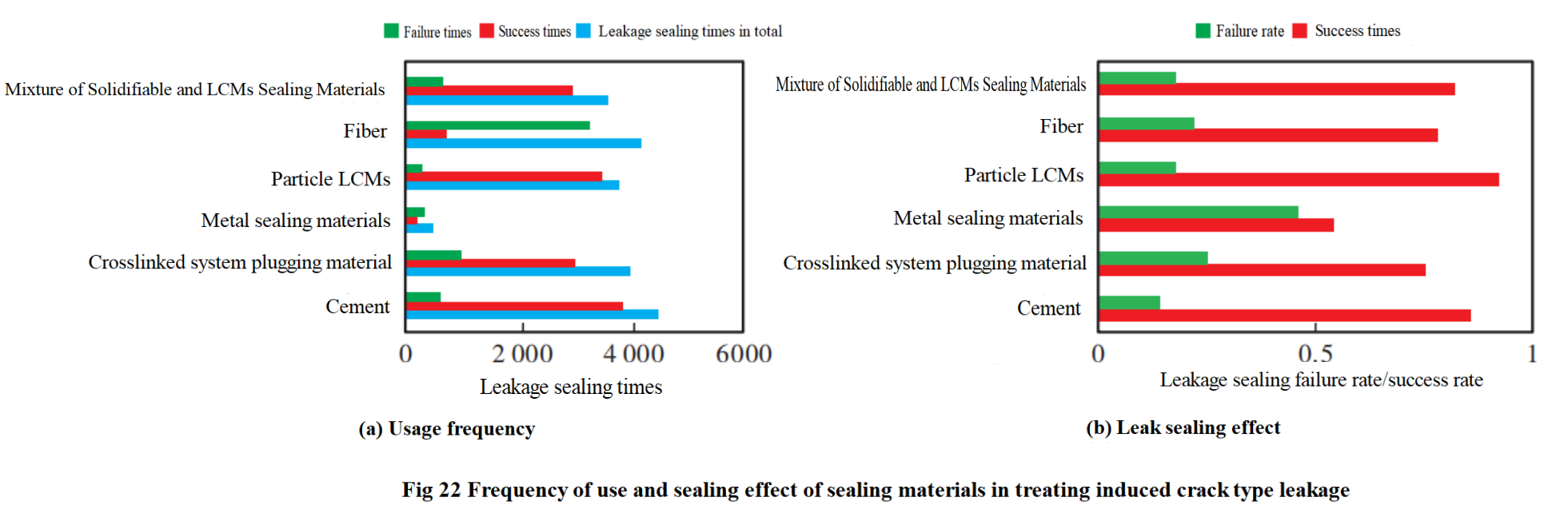

Induced fractures are different from natural fractures, which can occur at any time in geological history. Their properties depend on the geological environment at that time and are unstable.Induced fractures are generated during the drilling process with minimal changes in their properties, as most of the parameters that affect the length and width of fractures, such as bottomhole pressure, are known. Typically, two classic induced fracture models, PKN and KGD, are used to estimate the parameters of drilling induced fractures.Through the investigation of relevant literature at home and abroad in the past decade, it was found that the frequency of using plugging materials to control and eliminate induced fracture type leakage in drilling sites was in the order of particle LCMs, cement, solidifiable and LCMs mixture, fiber, cross-linked system and metal plugging materials, with plugging success rates of 92%, 86%, 82%, 78%, 75% and 54%, respectively. The specific statistical data is shown in Figure 22.Considering the success rate and cost of plugging, granular LCMs and cement plugging materials are currently the best plugging materials for treating induced crack type leaks.

4. Conclusions

1). According to the type of leakage channel, leakage is usually attributed to the following four leakage mechanisms: high permeability matrix leakage, karst cave leakage, natural crack leakage, and induced crack leakage.The existing drilling plugging materials can be roughly divided into three categories based on their physical plugging and chemical solidification plugging methods: solidifiable plugging materials, conventional plugging materials, and solidifiable and LCMs mixed plugging materials.

2). Solidifiable plugging materials were first applied in drilling plugging, with excellent plugging effect and stability. They are mostly used in high permeability matrix type leaks, with a plugging success rate of 91%. However, their disadvantages are also very obvious.The construction is complex and usually requires underground injection and chemical reaction before solidification; The time cost is high, and the curing process requires a certain amount of time; Poor reversibility, once cured, it is usually difficult to reverse and remove.

3). To solve the problems of complex construction, high time cost, and poor reversibility of solidifiable sealing materials, conventional sealing materials have been applied as another type of sealing material. They have the characteristics of easy use, low cost, fast sealing, high chemical stability, and wide applicability. They are mostly used for natural crack type leakage and induced crack type leakage, with sealing success rates of 75% and 92%, respectively. However, the disadvantages of conventional leak sealing materials are also very obvious, such as limited filling range, uneven filling, irreversibility, temperature and chemical limitations.

4). In order to solve the problem of plugging in extreme environments or special situations that cannot be addressed by solidifiable plugging materials and conventional plugging materials, a mixed plugging material of solidifiable and LCMs has been developed. This new type of mixed plugging material combines the solidification characteristics of solidifiable plugging materials with the fluidity of LCMs, and has a wider adaptability and better plugging effect. It is generally used in cave type leaks, with a plugging success rate of up to 89%.