Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

1.4 Induced Crack Type Leakage

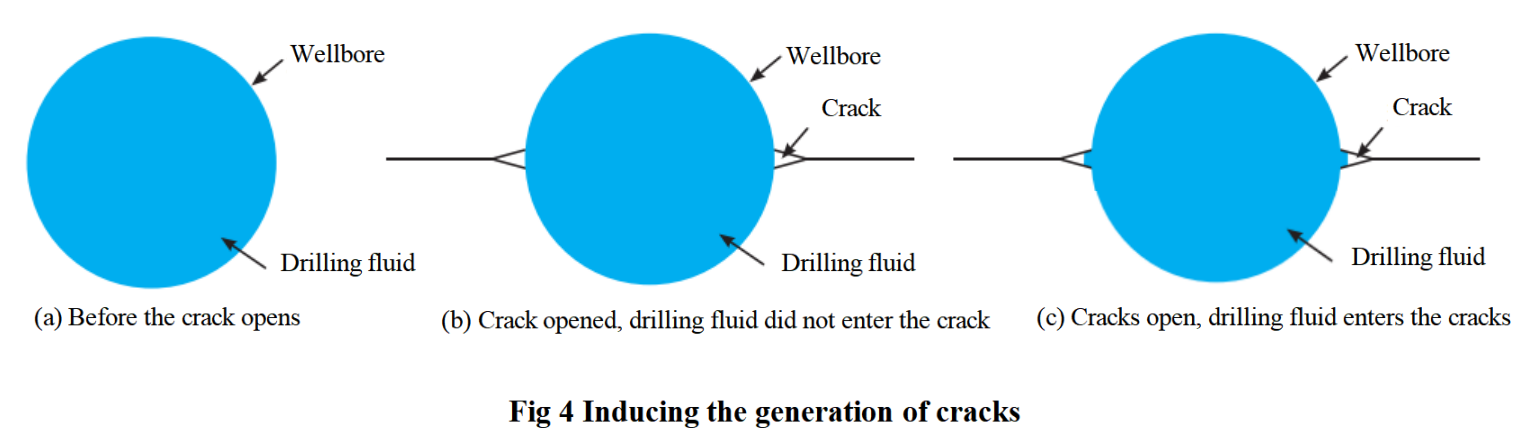

Induced fracture type leakage refers to intentionally causing or promoting the expansion of fractures in the formation by controlling the properties and construction parameters of the drilling fluid during the drilling process, resulting in the leakage of drilling fluid from the wellbore into the formation, leading to induced fracture type leakage.According to the papers published at the SPE/IADC drilling conference of the Institute of Petroleum Engineers, over 90% of the leakage comes from induced fracture type leakage.When the bottomhole pressure (BHP) exceeds the rupture pressure, induced fracture type leakage occurs. The rupture pressure depends on the original geostress and cracks form along the minimum resistance path, that is, the cracks are perpendicular to the minimum original geostress.If the liquid column pressure in a vertical wellbore exceeds the rupture pressure in a formation with σv>σH>σh (where σV is the vertical original stress, σH is the horizontal original stress, and σh is the minimum horizontal original stress), two cracks will form at the wellbore, and the crack surface will be perpendicular to the minimum original stress σh. However, if the original stress is σv<σH=σh, horizontal cracks will form.Whether the drilling fluid can enter the crack at the beginning of the crack depends on the width of the crack, the rheological properties of the drilling fluid, and the solid content. Only when the crack is large enough can the drilling fluid enter the crack, as shown in Figure 4.

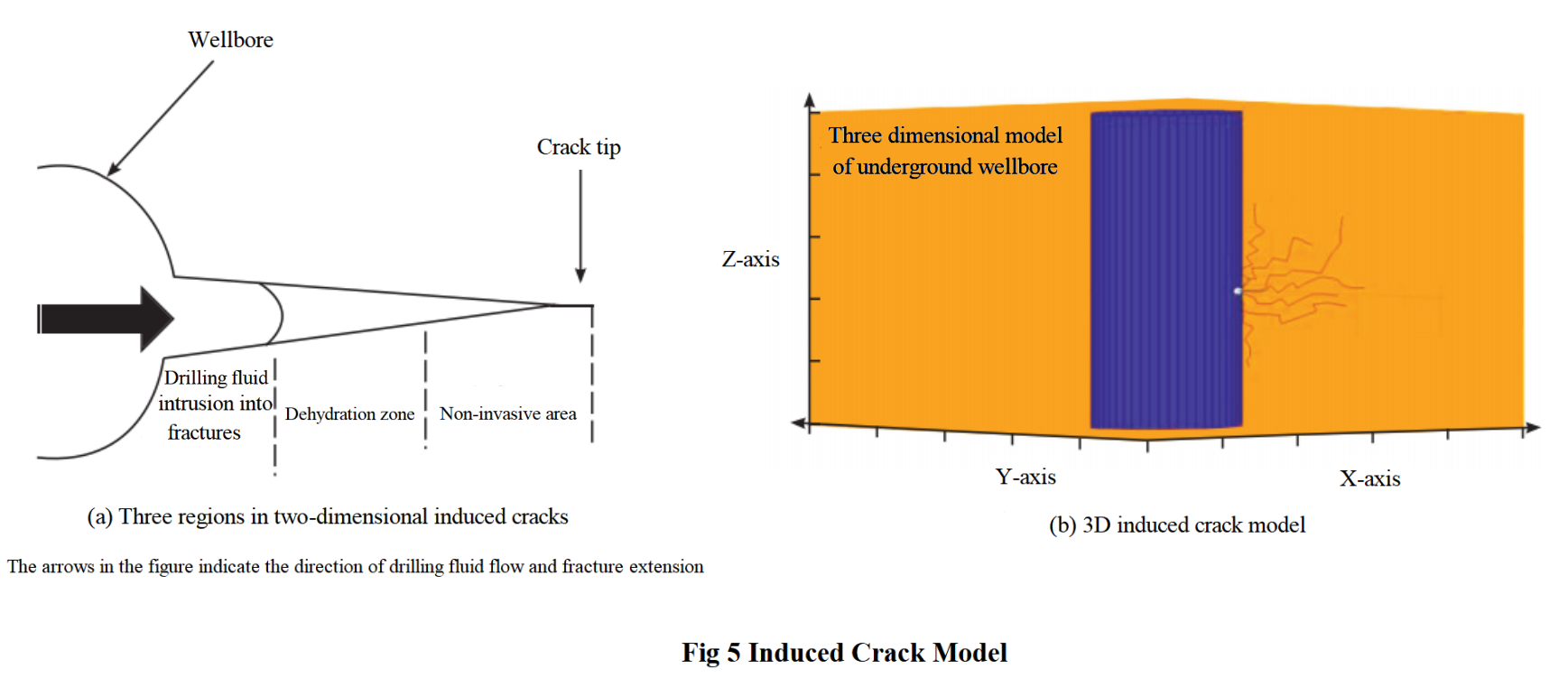

When the drilling fluid invades the fracture and extends, it can be divided into three different areas within the fracture. In the widest part of the fracture, which is closer to the wellbore, the remaining solid phase of the drilling fluid after filtration fills the fracture.The width of cracks that can be blocked depends on the type of drilling fluid. For drilling fluids with good filtration properties, larger crack widths can be blocked. There is an area between the water loss zone and the crack tip where the drilling fluid has not invaded, as shown in Figure 5 (a).

The two-dimensional legend shown in Figure 5 (a) is actually too simple because the crack extends in three-dimensional space, and the three-dimensional model is drawn with the bottom of the well as the coordinate origin. As shown in Figure 5 (b), the crack front edge will extend forward at the weakest point, so the crack front edge may not necessarily remain straight.The real crack surface is rough, and the degree of roughness depends on the type of rock. The presence of these factors will cause cracks to extend at specific locations, rather than simply along the entire front edge of the crack.

2. Research Progress on Leak Sealing Materials

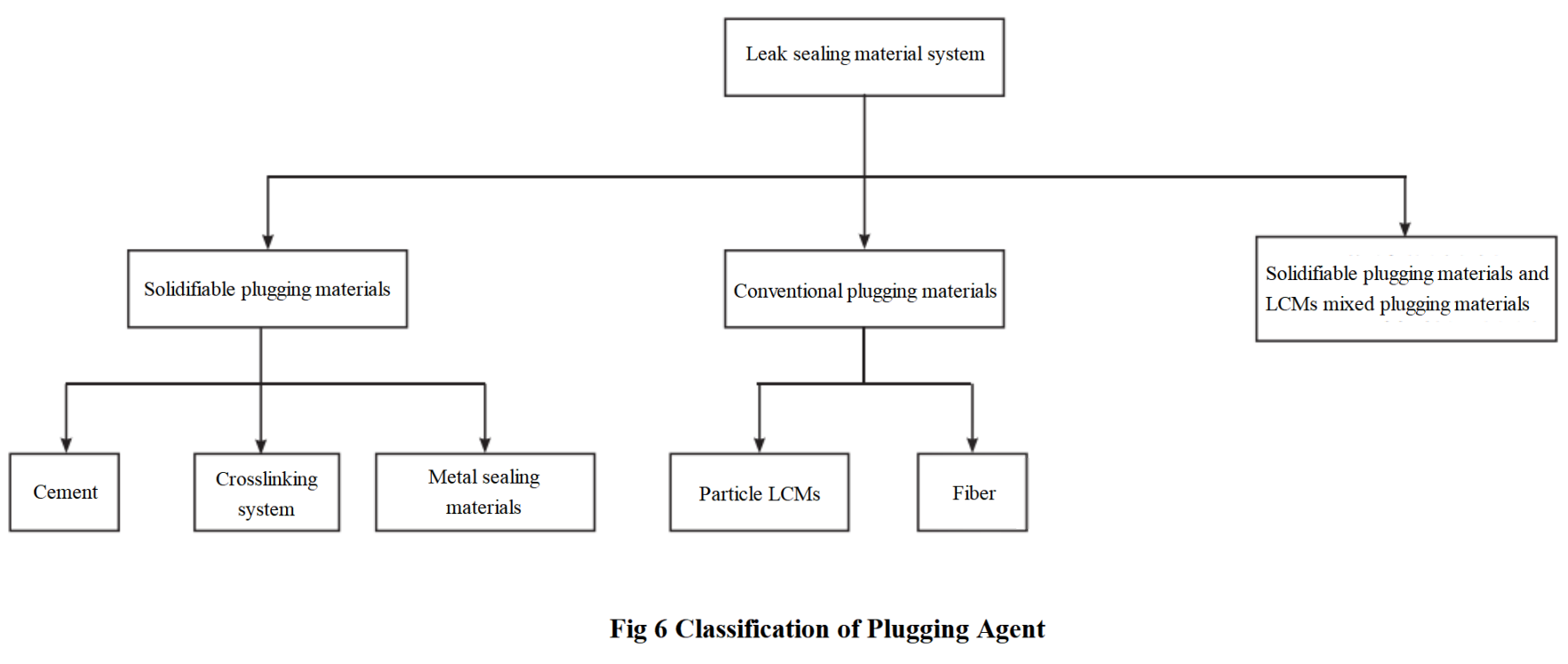

The sealing material is a kind of material that is composed of granular, fibrous or gel composites and can be pumped into the well to achieve the purpose of bridging and plugging fractures.Granular (including granular and flaky) materials, fiber materials and composite gel materials have been widely used in drilling plugging. At the same time, the combination of granular materials and fiber materials is also common in drilling plugging.According to the physical barriers and chemical reaction plugging methods of plugging materials, plugging materials can be divided into three categories: solidifiable plugging materials, conventional plugging materials, and solidifiable and LCMs mixed plugging materials.Physical barrier plugging refers to the formation of physical barriers by filling loopholes or cracks. When plugging materials enter the loopholes or cracks, they occupy space and fill it, thereby reducing or completely blocking the passage of fluids to achieve the purpose of plugging;Chemical reaction plugging refers to the solidification of plugging materials through chemical reactions, producing hard solidified products and forming a dense and strong plugging body. The current sealing materials can be subdivided into the following categories, as shown in Figure 6.

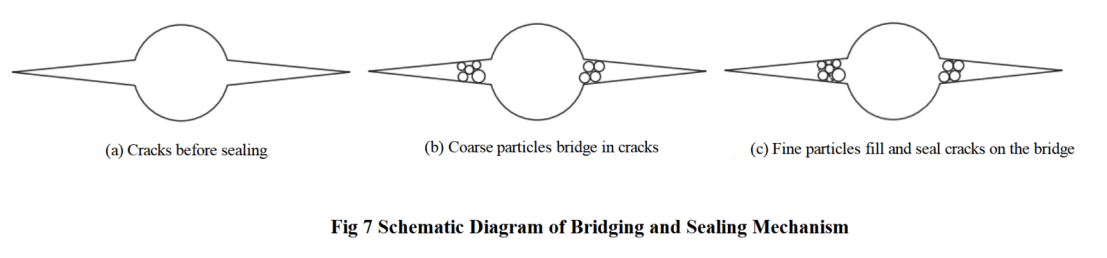

The process of sealing cracks with sealing materials can be roughly divided into the following four stages: dispersion, bridging, sealing, and support.The difference between bridging and plugging is that bridging can provide mechanical strength, but bridging is formed by relatively rough particles with large gaps, resulting in high permeability and inability to form an effective plugging zone.Therefore, in order to completely control leakage, the gaps between bridging particles must be filled with smaller particles to achieve the goal of completely sealing and plugging lost channels. The bridging and plugging mechanisms are shown in Figure 7.

2.1 Solidifiable Sealing Materials

Solidifiable plugging material is a material that is pumped into the wellbore in liquid form and solidifies the plugging layer underground. Curing sealing materials can include cement, viscous substances, bentonite, oil-based drilling fluid systems, cross-linking systems, and other materials. Before curing, in order to facilitate pumping, the curable sealing material should have a sufficiently low apparent viscosity.During the solidification process, the selected material should have sufficient strength to withstand pressure fluctuations in the wellbore. If the selected curable plugging material can also generate some expansion, it can enhance its plugging ability and improve the strength of the plugging zone.One important characteristic of curable sealing materials is yield stress, which determines the stability of the sealing zone under wellbore pressure difference. The mathematical expression of yield stress is shown in formula (2).

.png)

Where

∇P - yield stress, Pa/m;

wh - hydraulic width of cracks, m;

τY - yield stress of the sealing material, Pa.

According to formula (2), the ability of a curable sealing material to withstand pressure fluctuations is determined by its yield stress after solidification.

2.1.1 Cement Sealing Material

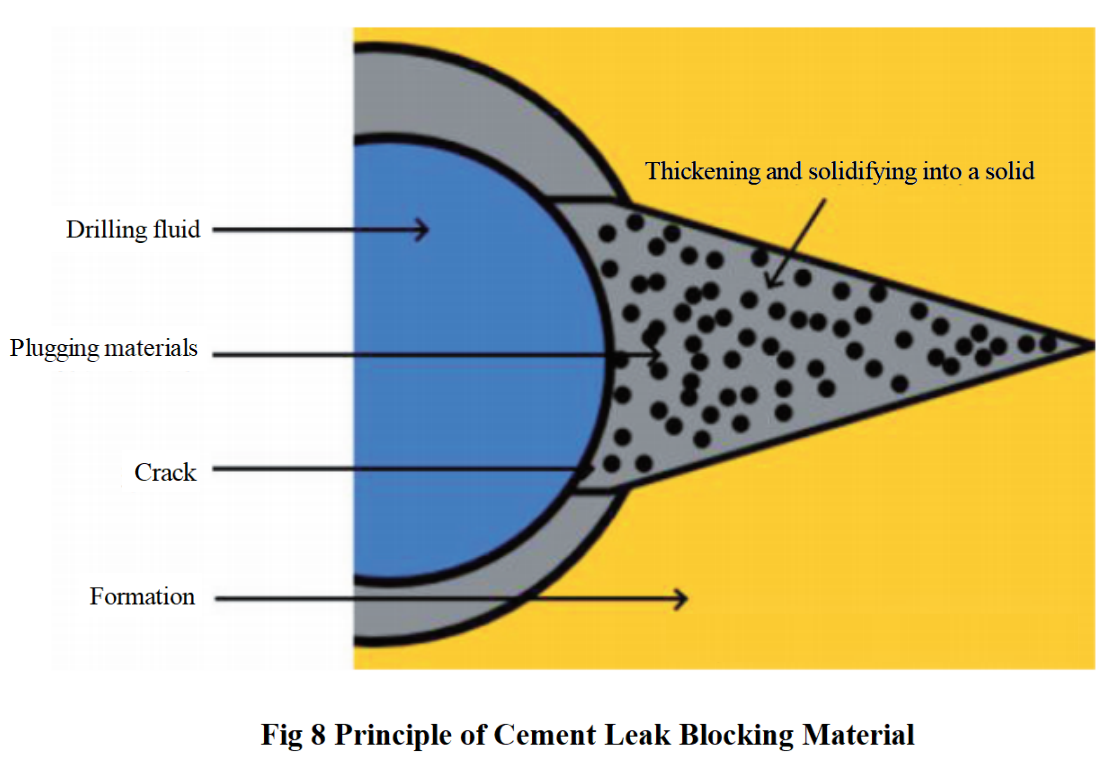

The principle of cement plugging is to form a sturdy sealing body through the diffusion, filling, and solidification of cement slurry, as shown in Figure 8.In situations where other materials cannot play a role in sealing, cement may be an effective sealing material with stronger compressive strength compared to other materials, which can improve the sealing effect. Therefore, cement is often used to deal with severe leakage problems in highly permeable sandstone formations.Cement is considered one of the few effective treatment agents for dealing with leakage in karst reservoirs.Bentonite, particle plugging materials (calcium carbonate), and fiber based plugging materials can all be used as additives in cement systems. Han et al. proposed a new composite material that blends water-based epoxy resin with ultrafine ordinary Portland cement sulfoaluminate cement, which can quickly fill the wellbore leakage area and is commonly used in low-permeability wellbore leaks, such as solid leakage and mud layer crack leakage.Wang Sheng and others have developed a new material for deep hole nanocomposite cement-based wall protection and leakage prevention. At a temperature of 100℃, the initial flowability of the material can reach 28cm, and the initial stage of decline is relatively gentle, showing good stability.In order to solve the problem of leakage in complex formations such as low pressure formations and fault fractures in the southern margin of the Junggar Basin, Xinjiang Oilfield, Liu Zheng and others independently developed the oil-based expansive plugging agent DHF series, which has excellent compressive strength and rebound performance. The compressive capacity can reach 30 MPa, and the rebound rate is 12.2% -15.5%. This series of plugging agent also shows good high-temperature resistance, and can withstand the high temperature environment of 160℃.To solve the leakage problems of sandstone infiltration and interface bonding in the Toptai area, Xianming et al. used a mixture of fibers and cement for plugging and achieved good plugging results.To solve the serious leakage problem, Mata et al. used magnesium oxide cross-linked cement to seal the fractured zone, which can achieve no leakage during cementing operations. The injection amount of magnesium oxide cross-linked cement is 0.5-1.0 L/m, but the flow ability of cement in the leakage channel may also become an unfavorable factor restricting the sealing effect before it is completely solidified.

2.1.2 Cross Linked System Type Sealing Materials

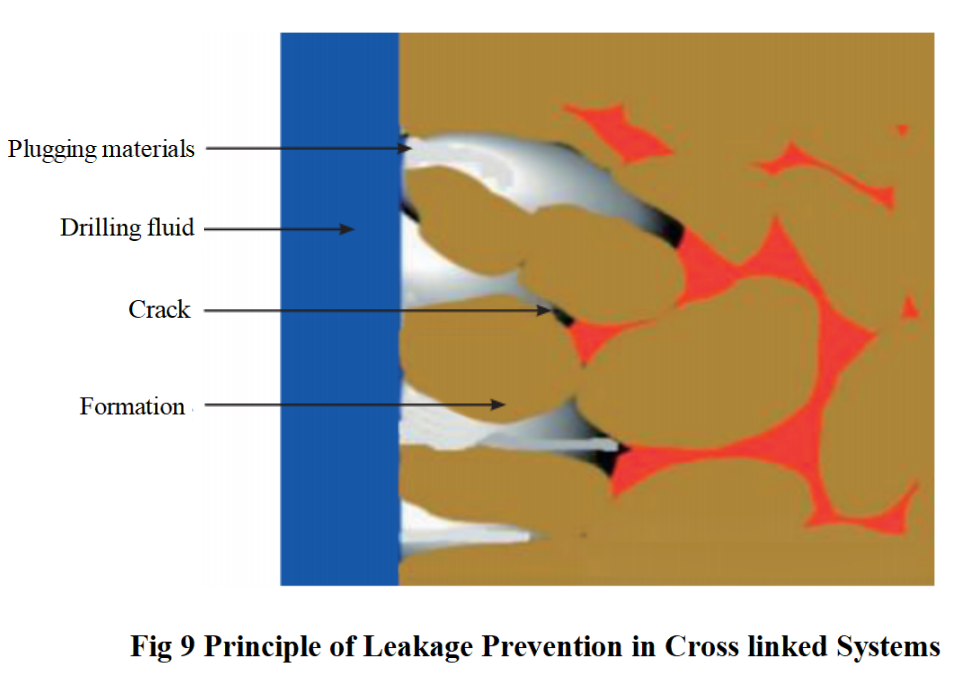

Crosslinked system plugging materials are triggered by time and temperature or by shearing at the bit to achieve gel reaction of liquid, thus forming a stable and impermeable plugging body. They are characterized by rapid curing, high temperature resistance, acid and alkali resistance, and high compressive strength. The plugging principle is shown in Figure 9.

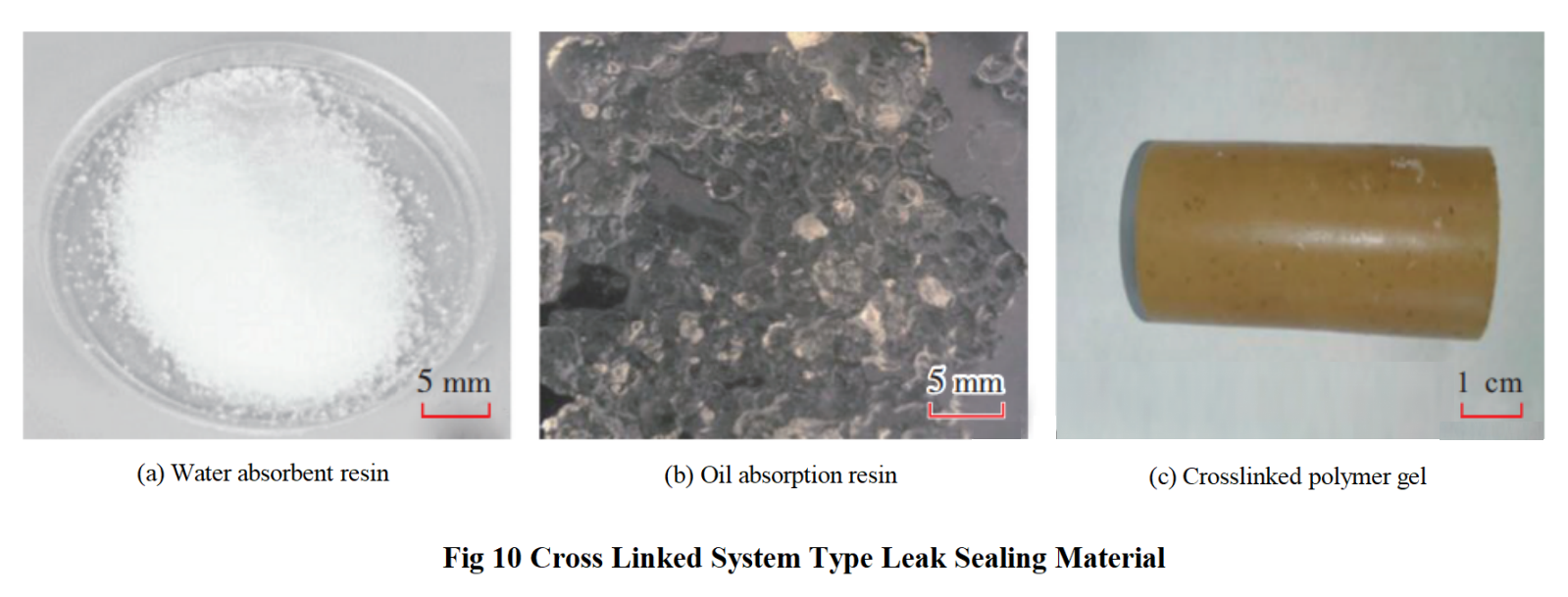

Usually, cross-linked system plugging materials react with water to form solidified products. Ali et al. developed a composite plugging material called BLCM, which is mainly composed of special fiber particles, plant fibers, and polymers. When BLCM plugging material is pumped into the leakage area, it expands after absorbing water, forming a network structure with certain strength and viscoelasticity. It then enters pores and cracks of different sizes and shapes through deformation ability, playing a plugging effect, as shown in Figure 10 (a).Oil absorbing resin plugging material is a porous material with high oil absorption capacity and large surface area, which can quickly absorb oil stains and fix them on the surface of the material. Its characteristics include efficient removal of oil stains, reusability, environmental friendliness, and suitability for various types and scenarios of oil stains, as shown in Figure 10 (b).Wang Zhonghua used polymer gel plugging agent in combination with other materials to solve the malignant leakage in the drilling process, which is particularly effective for carbonate rock, fracture developed formation and hole leakage. The cross-linked polymer pattern is shown in Figure 10 (c).

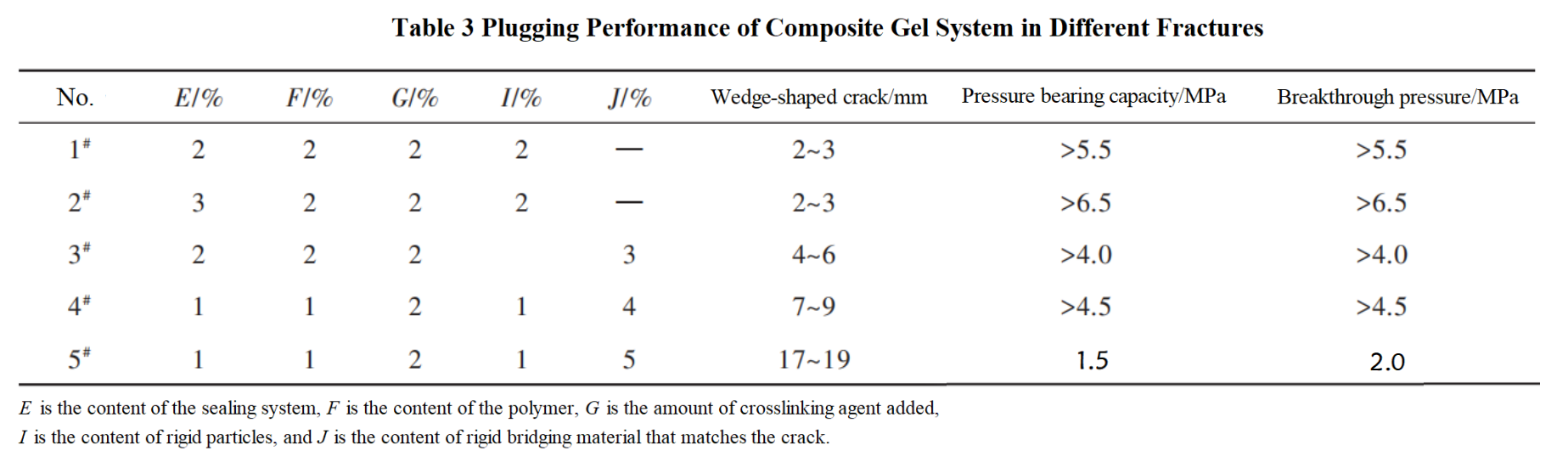

Scholars have also developed cross-linked polymers with unique drainage capabilities. Luo Xingshu and others chose to use polyacrylamide as the gelling agent and trivalent chromium and phenolic aldehyde as the cross-linking agent to form a polymer gel, which has unique drainage and plugging ability during the drilling of oil and gas wells.Zhou et al. developed a polymer gel. The gel was prepared by chemical crosslinking of triethanolamine, titanium diisopropyl alcohol (TE) and polyvinyl alcohol (PVA) solution. The - OH on the PVA molecular chain was chemically crosslinked with Ti4+ions in TE crosslinker through complexation reaction. The crosslinked chain segment can inhibit the chain movement to form a stable "crab like structure" gel.Considering the gel strength and gel time, when the concentration of TE crosslinker is 2.2%, the gel performance is the best. Wang Jianjun and others developed an organic/inorganic composite gel plugging material, which is mainly composed of functional polymer, cross-linking agent and rigid inorganic material. See Table 3 for the plugging performance of this composite gel in different fractures.

Common cross-linking system plugging materials include FORM-A-PLUG, FORM-A-SET, FORM-A-SETAKX and other gel plugging materials series launched by M-I Company, ZNT special gel developed by Academician Luo Pingya's team, and high-temperature gel plugging agent and shear response gel plugging agent developed by Academician Sun Jinsheng's team.