Research Progress of New oil well Cement Dispersants in China

Abstract

Adding admixtures, especially dispersants, to cement paste, mortar and concrete has been recognized as an effective measure to improve the strength of cement products and concrete, change the operational performance of concrete, save cement, steel bars, and reduce energy consumption. With the vigorous development of the petroleum industry, oil well cement dispersants in China have been widely used and developed significantly in recent years. This article mainly introduces the preparation and dispersion performance of several new dispersants in China, and explores the effects of chemical composition and functional group characteristics on the performance of dispersants.

With the development of high-tech completion technology, the requirements for the performance of cementing slurry are also increasing. The use of oil well cement additives is an effective method to improve the performance of cement slurry and improve the quality of cementing. Oil well cement dispersant is a very important type of oil well cement additive, which endows fresh cement slurry with good flowability and high strength after solidification under low water cement ratio. The main oil well cement dispersants that have been successfully applied include β- Naphthalene sulfonic acid formaldehyde condensate, which is synthesized from naphthalene through sulfonation, condensation, neutralization, and other steps, has good dispersion ability. However, the product contains a considerable amount of sodium sulfate generated by neutralizing excessive sulfuric acid, and the presence of sodium sulfate can corrode cement paste; Sulfonated acetone formaldehyde condensate is currently the leading product of oil well cement dispersant in China. It is obtained through acetone sulfonation and formaldehyde condensation, and has good dispersion ability. The use temperature can reach 150℃, making it the best high-temperature oil well cement dispersant in China.

Daqing Oilfield and major domestic oilfields have entered the mid to late stage of development, and the development of deep or ultra deep wells is becoming increasingly important. The depth of a well with a bottom hole temperature of 150 ℃ is about 5000m. If the well depth is above 5000m, all dispersants will not meet the cementing requirements at present. Therefore, it is necessary to develop high-temperature oil well cement dispersants.

There have been reports on the research of oil well cement dispersants in China, such as SSMA copolymer, sulfonated polystyrene SPS, and sulfonated acetone formaldehyde condensate. The first two have not been widely promoted and applied due to their complex preparation processes and high production costs; Sulfonated acetone formaldehyde condensate has been industrialized and successfully applied in cementing, becoming the leading product of oil well dispersants in China. There have been reports on the preparation of high-efficiency water reducing agents for concrete using p-aminobenzenesulfonate as the main raw material through condensation with formaldehyde, but research reports and patents on its use as a dispersant for oil well cement have not been reported yet.

1. The Function and Principle of Dispersants

The main function of dispersants is to reduce the plastic viscosity and yield value of cement slurry: The plastic viscosity is determined by the size, shape, and quantity of solid particles contained in a unit volume of cement slurry; The yield strength is determined by the charge carried by solid phase molecules or particles and the assumed molecular particle structure that aggregates in the cement slurry.

The addition of dispersant can weaken and break up the cluster connection between particles, release free water, change the properties of hydration products, reduce internal friction resistance, destroy gel, and reduce plastic viscosity. The yield value is equivalent to the electrostatic attraction required to neutralize the interaction between cement particles, causing them to begin moving. A negatively charged dispersant neutralizes the attraction between positively charged particles through adsorption on cement particles. On the contrary, hydrated calcium silicate carries a positive charge and repels the charges on the cement particles, causing the cement to separate into single particles. The numerical value of attracting or repelling charges is the yield value, which can change the rheological mode. When all positive adsorption positions are saturated, the optimal concentration of the dispersant is reached, and the consistency of the cement slurry is improved. However, excessive dispersion can also damage the microstructure established by the same electrostatic effect, causing cement particles to settle or free water to increase.

2. The Types of oil well Cement Dispersants

Dispersants mainly achieve the best rheological properties of cement slurry by adjusting the surface charge of cement particles. According to the chemical structure and performance of dispersants, they can be divided into three categories: sulfonates, carboxylates, and cement conditioners.

2.1 Sulfonates

Sulfonates are the most commonly used oil well cement dispersants. In the molecules of such dispersants, there are generally 5-50 sulfonic acid groups, which are connected to the main chains of highly branched macromolecules. Structurally, branched polymers are the most ideal dispersants, as this branched macromolecular structure is crucial for bridging cement particles within the required dispersant concentration range. There are several types of sulfonate dispersants:

(1) . Lignosulfonates, mainly calcium lignosulfonate and iron oxide salts. Calcium lignosulfonate is an anionic surfactant with a basic structural formula of phenylmethylpropane derivative. It ionizes into anionic hydrophilic groups and Ca2+cations in aqueous solution, and has dual effects of retarding and dispersing. It has a wide range of sources and a low price.

(2) . Polynaphthalene sulfonate, abbreviated as FDN. Its chemical structure contains aromatic conjugated rings, which can firmly adsorb on the surface of cement particles and have good dispersion effect. It has the advantages of obvious water reducing effect, small air entrainment, and rapid early strength development.

(3) . Melamine sulfonate, also known as melamine resin or melamine resin, which has a stable six membered conjugated ring and is a non entrained high-efficiency dispersant. Its hydrophilic group is sulfomethyl, which has a stronger hydration effect than sulfomethyl in general dispersants, resulting in a more significant dispersion effect.

(4) . Aldehyde ketone addition polymer, made from acetone, formaldehyde and sodium bisulfite. It has advantages of low cost, obvious effect, and high temperature resistance.

(5) . Sulfite modified phenolic resin is a dispersant prepared from a mixture of bisulfite and phenol formaldehyde, which has the characteristics of low cost, high temperature resistance, and good dispersion effect.

(6) . Other sulfonated polymers, such as sulfonated tannins, sulfonated tannins, etc.

2.2 Carboxylates

Carboxylate dispersants include acrylamide/acrylic acid copolymers or methacrylamide/methacrylic acid copolymers, styrene, maleic anhydride copolymers, as well as some low molecular weight sugars and carboxylic acids or their salts.

(1) . Acrylamide/acrylic acid copolymer or methacrylamide/methacrylic acid copolymer, both of which have excellent water loss and drag reduction effects, and can withstand high temperatures of over 150℃.

(2) . Polymaleic anhydride mainly includes substances such as maleic anhydride.

(3) . The styrene maleic anhydride sulfonated copolymer has a low dosage and only requires 0.01%~2.0%.

2.3 Cement Conditioners

Cement conditioners can damage the bonding strength or static shear force, reduce the yield value or dynamic shear force, and are the nemesis of thixotropic cement. This dispersant improves the flow performance by changing the flow pattern of cement slurry, thereby reducing the steady flow pump speed.

3. New Type of oil well Cement Dispersants

3.1 Modified Lignosulfonate

Lignosulfonate dispersants have been studied and produced in the United States since the 1930s, with a long history. It has played an important role in the construction of highways, hydraulic dams, bridges, and various buildings.

Sun Zhenping et al. from Tongji University added appropriate polymer solution, peroxide initiator, and catalyst dropwise to the lignin sulfonate dispersant (LS) solution, and synthesized it through free radical reaction. After dripping, the modified lignosulfonate dispersant (MLS) is obtained by holding it at a certain temperature for several hours. Dry LS and MLS samples separately, and crush 0.5-1.0mg solid samples with 150mg KBr. Press them into thin sheets using a tablet press for infrared spectroscopy testing. Comparing the infrared spectra before and after LS modification, it can be seen that there is a certain difference between the two. Significant carboxyl characteristic peaks appeared in MLS; The absorption wave number at 1728.27cm-1 represents the stretching vibration of C=O in the carboxyl group; The stretching vibration of O-H in the carboxyl group is around the absorption wave number of 3000cm-1; The absorption wave number at 1456.82cm-1 is the stretching vibration of C-O in the carboxyl group; The strong absorption band with absorption wave numbers of 1320-1210cm-1 is the in-plane deformation of O-H in the carboxyl group.

3.2 High Performance Acrylate-ACM- Acrylamide Ternary Copolymer

Polycarboxylic acid dispersants have the advantages of low dosage, high water reduction rate and significant strength growth. Its water reduction rate is generally above 18%, mainly used for the preparation of high-strength and high fluidity concrete and the water reduction of ordinary concrete.

Liu Derong from Sichuan University of Technology added acrylic acid, dodecyl acrylate, and acrylamide in a 1:1:1 molar ratio to a three necked flask, and added 95% ethanol with a monomer mass of 1.5 times as the solvent, then add 5% of the monomer mass of benzoyl peroxide as the initiator. Heat to 73℃, react for 3 hours, evaporate ethanol, add deionized water, and neutralize acrylic acid with NaOH to convert it into sodium salt, then prepare to the required concentration. Using the same method, change the molar ratio of acrylic acid, acrylate, and acrylamide to synthesize ternary copolymer dispersants with different proportions. Copolymerization of butyl acrylate, hexadecyl acrylate, and octadecyl acrylate with acrylic acid and acrylamide.

4. Summarize

By adding a dispersant, one of the three major additives for oil well cement, the plastic viscosity and yield value of the cement slurry can be reduced, and turbulent flow can be achieved at lower pump pressure and return velocity, thereby improving the displacement efficiency of the cement slurry. Due to the reduction of pump pressure, it reduces well leakage and early dehydration of cement slurry.

Adding dispersants can also ensure that under the same fluidity, the water-cement ratio is reduced, and the density and strength of cement slurry are improved. Meantime it can also change the microstructure of cement stone, making the structure of cement stone more dense, improving the durability, corrosion resistance, and impermeability of cement, thereby greatly improving the quality of cementing.

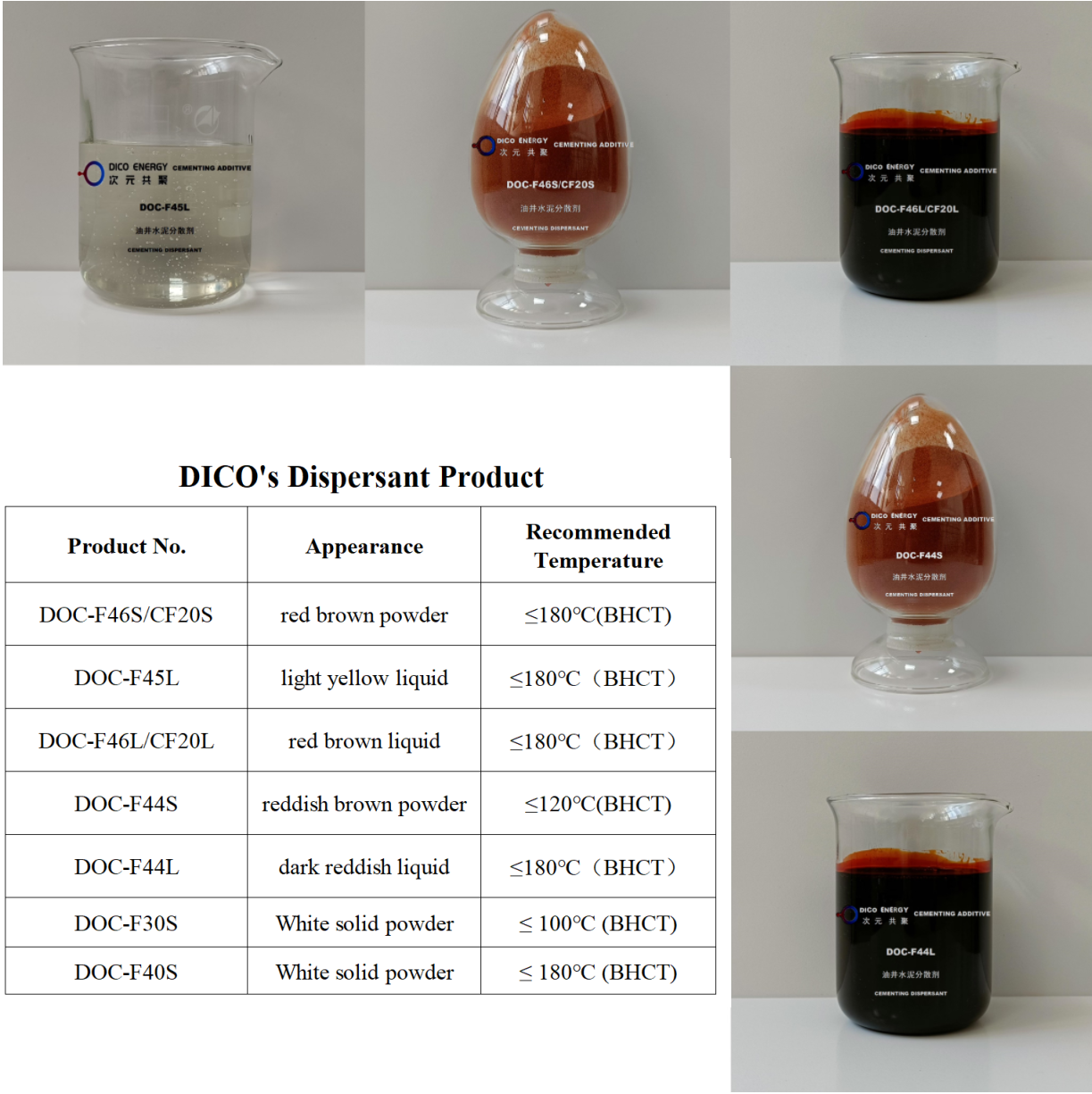

Below list and pic are the cementing dispersant products we developed and produced. For the specific information of each product, you can search it on our official website www.dicoenergy.com. Welcome inquiry and purchase.