Preparation and Performance Study of Deep Shale Sealing Agent Based on Montmorillonite Modification(Part 1)

Abstract

Deep shale natural fractures are developed, and there are generally micro/nano scale fractures. However, the existing micro/nano particle sealing agents have problems such as easy aggregation and large dosage, leading to wellbore instability, stuck drilling and other complex underground situations. To solve this problem, firstly, layered montmorillonite is used as the raw material to prepare nano montmorillonite. Then, surface modification of nano montmorillonite is carried out through atomic transfer radical polymerization to synthesize a hydrophobic nano sealing agent N-MMT. The sealing characteristics of N-MMT were evaluated using infrared spectroscopy, energy spectrum analysis, particle size analysis, and scanning electron microscopy, as well as core self suction test, microporous filter membrane filtration loss test, and high-temperature aging test. The experimental results show that the nano sealing agent N-MMT has a pre designed functional group with an average particle size of 526nm, which can significantly reduce the self suction ability of the rock core. The self suction capacity of shale rock core is reduced by 66.7%, and it has good compatibility with conventional oil-based drilling fluid treatment agents. The high-temperature and high-pressure filtration loss is reduced by 47%, and the demulsification voltage is increased, resulting in stronger stability. The nano sealing agent N-MMT can adsorb at the micro nano pores and fractures of shale to form a sealing film, preventing drilling filtrate from entering deep shale fractures, protecting wellbore stability, and has good application prospects.

At present, China's unconventional deep oil and gas resources, represented by shale oil and shale gas, have received great attention. Deep/ultra deep geological conditions are complex, with natural fractures developing in deep shale and widespread micro nano scale fractures. With the infiltration of drilling fluid filtrate, the fractures will further expand, leading to collapse, blockage, and even serious problems such as stuck drilling and wellbore scrapping, posing great difficulties for the safe and efficient development of deep oil and gas. Nanomaterials have the characteristics of small size and uniform particle size, which can enter nanoscale cracks and pores to form a sealing layer, prevent further invasion of drilling fluid filtrate, and achieve the goal of stabilizing the wellbore. At present, on-site construction often uses the addition of nano SiO2, nano Fe3O4, ultrafine CaCO3, etc. to drilling fluid for sealing, but the particles are prone to agglomeration and the amount used is large. Montmorillonite is a typical layered clay mineral with abundant reserves and low prices. It has good ion exchange performance and hydration expansion properties. Under mechanical forces, it is easy to peel off into nanosheets and has a huge specific surface area and abundant active sites. It can be used to prepare advanced mineral functional materials such as environmental functional materials, energy storage materials, flame retardant materials, nanofluid channels, and smart materials.

Montmorillonite is often modified and used in drilling fluid. Organic montmorillonite can form gel in drilling fluid, which has good thixotropy, lubricity and stability. Lai Nanjun and others distributed urea formaldehyde resin between the layers of modified montmorillonite, and finally added a composite agent for solidification to obtain a horizontal well plugging agent. Yan Bowen et al. used Momordica grosvenorii polysaccharide and organically modified montmorillonite and iron powder particles to form a plugging agent that has certain compressive strength and high temperature resistance and can effectively seal formation micro fractures. The organic soil formed by the combination of octadecyldimethylbenzylammonium chloride and montmorillonite by Song Haiming and others has a temperature resistance of 210℃, which is suitable for the preparation of high-temperature oil-based drilling fluids. At present, although there have been numerous studies on the modification of montmorillonite, there are few reports on the application of nanoscale montmorillonite in shale oil-based drilling fluids.

Based on the above situation, this article obtains low dimensional nano montmorillonite by peeling off montmorillonite with a layered structure. Organic molecules are grafted onto the surface of the nano montmorillonite using atomic transfer radical polymerization to prepare the nano blocking agent N-MMT. Its structure is characterized through indoor experiments and its high-temperature sealing performance is evaluated.

1. Synthesis of Nano Sealing Agents

1.1 Synthetic Principle

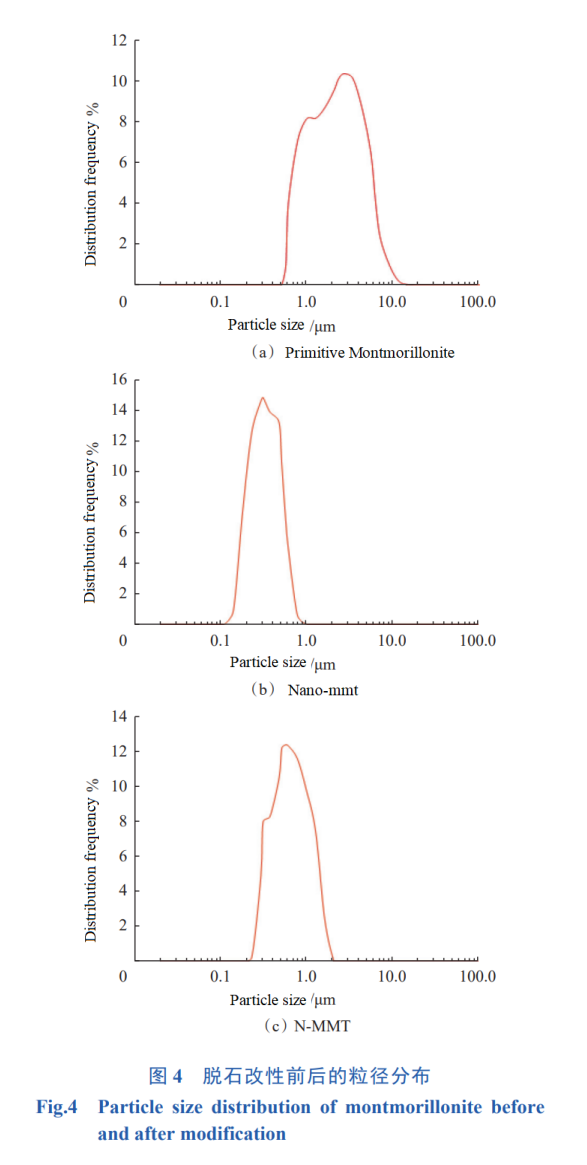

When natural multilayer structured montmorillonite is dispersed in water, it undergoes hydration and expansion. In addition, the hydration of interlayer cations increases the interlayer spacing of montmorillonite, which is further peeled off under ultrasound, becoming a few layers of nano montmorillonite. Subsequently, organic molecular chains were grafted onto the surface of nano montmorillonite using atomic transfer radical polymerization (ATRP), and the -OH groups on the surface of montmorillonite were coupled with 3-aminopropyltriethoxysilane to introduce primary amine groups; Replace the active H atom in the primary amine group with the nucleophilic bromine atom in 2-bromoisobutyryl bromide, and construct a halogenated -C-Br group for subsequent ATRP oxidation-reduction; Perform ATRP polymerization on the R-Br compound obtained from the reaction to obtain a nano sealing agent (N-MMT). The preparation and modification process of montmorillonite nanosheets are shown in Figure 1.

1.2 Preparation Steps

1.2.1 Preparation of Montmorillonite Nanosheets

Add 1.0g of montmorillonite to 100mL of deionized water and stir at a speed of 300r/min for 12 hours at room temperature to prepare a montmorillonite suspension with a mass fraction of 1.0%; Place it in an ultrasonic cell crusher and sonicate for 5 minutes at a power of 450W to obtain a low dimensional montmorillonite suspension. Then 0.1g of octadecyltrimethylammonium bromide was added and stirred at 50℃ for 5 hours to achieve sufficient hydration, dispersion, and stripping, further reducing the structural dimension and obtaining low dimensional nano montmorillonite; Wash the reduced montmorillonite repeatedly with anhydrous ethanol, add 200mL of deionized water and stir to obtain a nano montmorillonite suspension.

1.2.2 Modification of Montmorillonite Nanosheets

Under constant temperature of 50℃, 0.2mL of 3-aminopropyltriethoxysilane aqueous solution was added dropwise to the above montmorillonite suspension, and stirred thoroughly for 24 hours to endow the surface of montmorillonite nanosheets with active primary amine groups. After the reaction is completed, centrifuge at a speed of 5000r/min for 5 minutes, then wash three times with anhydrous ethanol. The precipitate obtained from centrifugation is vacuum dried at a temperature of 85℃ for 12 hours to obtain aminated montmorillonite.

Perform ATRP reaction, place 1.0g of aminated montmorillonite, 20mL of methanol, and 20mL of ultrapure water in a 250mL three necked flask, and add 0.4mL of 2-bromoisobutyryl bromide, 2.0mL of 2,2'- bipyridine complex, 0.02g of cuprous bromide, and 0.1mL of ethyl methacrylate under magnetic stirring at a speed of 300r/min; Then gradually heat up to 90℃, maintain condensation reflux, and react freely at a constant temperature for 6 hours. After the reaction is completed, the reaction solution is centrifuged at a speed of 5000 r/min for 5 minutes, and the precipitate is washed with methanol; Centrifuge, clean, repeat 3 times, and finally dry under vacuum at 105℃ for 12 hours to obtain the sealing agent N-MMT.

2. Characterization of Nano Sealing Agent

2.1 Infrared Spectroscopy

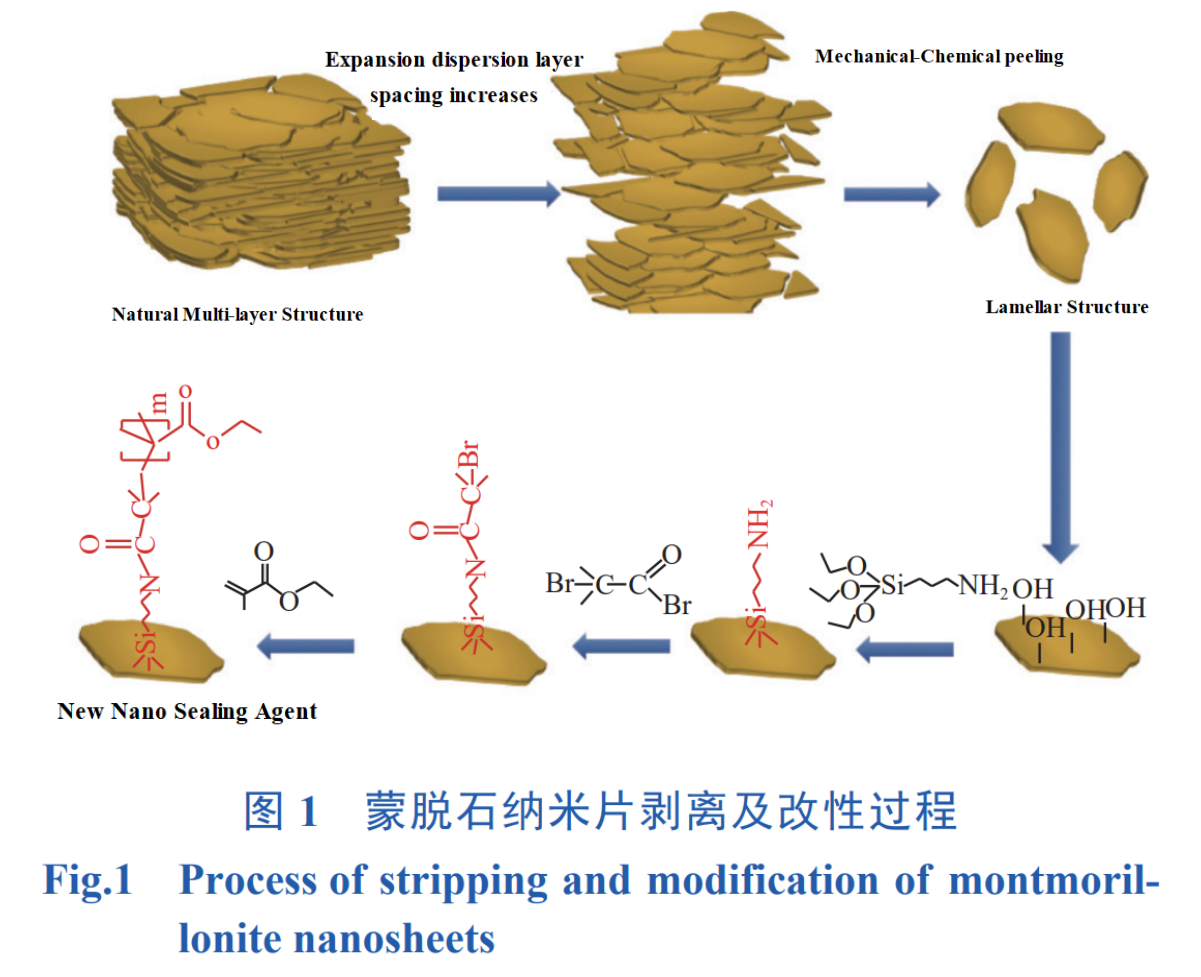

The infrared spectrum of the sample was measured using Nicolet 6700 Fourier transform infrared spectrometer, as shown in Figure 2. The infrared spectrum of the original montmorillonite shows significant absorption peaks at 1030,800 and 625cm-1, representing the Si-O-Si stretching vibration absorption peak and Si-O-Si deformation vibration absorption peak, respectively. The broad absorption peak at 3400cm-1 belongs to the characteristic peak of bound water -OH, while the significant absorption peak at 3630cm-1 represents the characteristic absorption peak of Mg-Al-OH in montmorillonite. After surface modification of nano montmorillonite, several absorption peaks were significantly increased. Among them, the strong absorption peaks at 2920 and 2850 cm-1 are attributed to the stretching vibration of -CH3 and -CH2-, and the absorption peak at 1350 cm-1 is attributed to the stretching vibration of C-N; In addition, the absorption peak at 1730cm-1 is attributed to the stretching vibration of ester carbonyl groups, which is a characteristic peak of ethyl methacrylate. The above characteristic peaks indicate that the modified nano montmorillonite has successfully grafted the pre designed functional groups.

2.2 Elemental Analysis

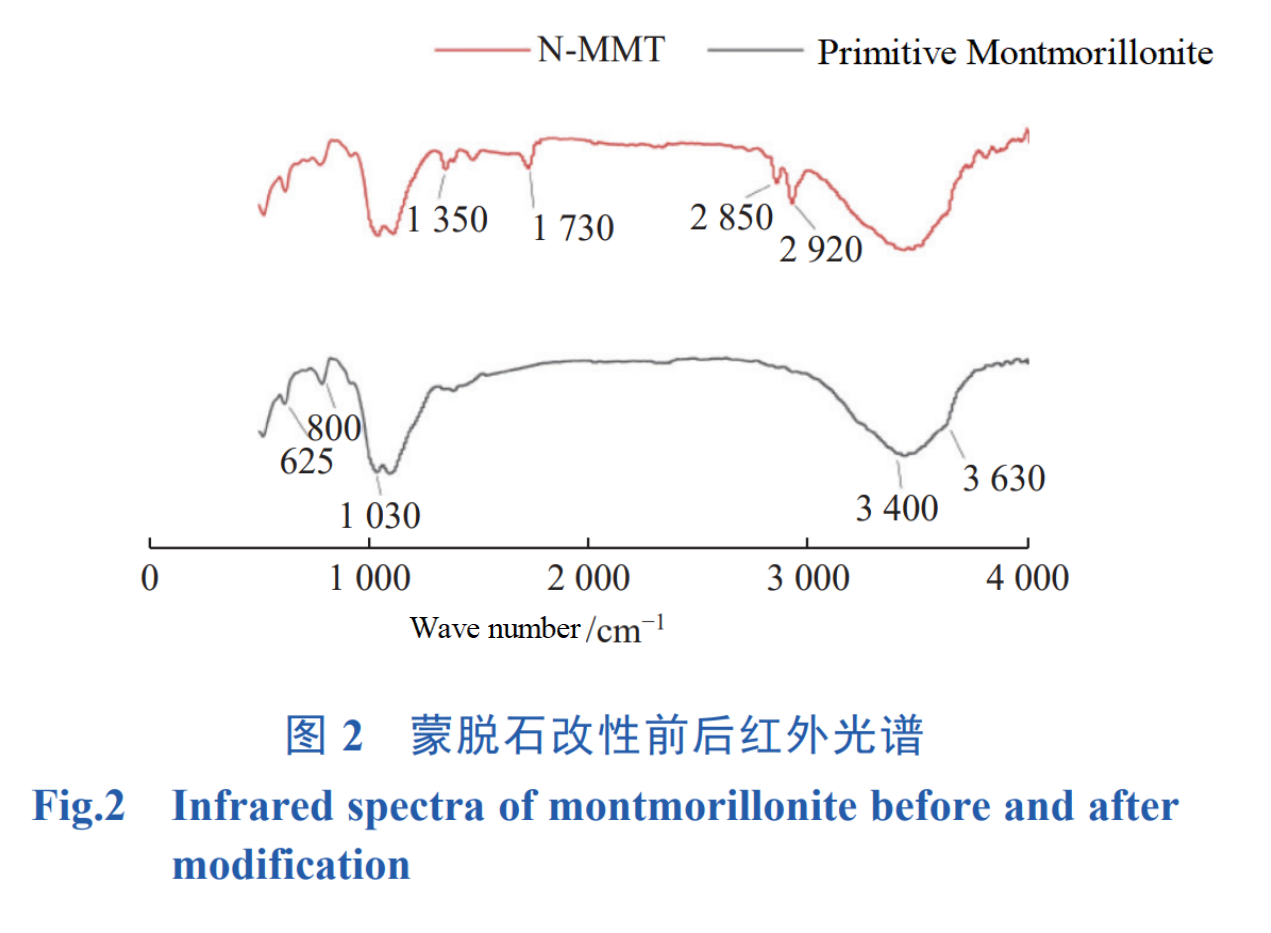

To further verify the composition of the flexible graft structure, elemental analysis was performed on the surface growth structure using an energy dispersive X-ray analyzer (Phenmo pro X), and the results are shown in Figure 3. The relative mass percentages of the main elements O, Si, Al, and Na in the original montmorillonite sample are 47.25%, 32.27%, 6.69%, and 2.40%, while the spectra of modified montmorillonite nanosheets show absorption peaks of C and N. The relative mass percentages of C, O, Si, Al, Na, and N are 29.37%, 32.37%, 22.58%, 2.60%, 4.60%, and 1.50%, indicating the successful grafting of organic molecules on the surface of montmorillonite.

2.3 Particle Size Analysis

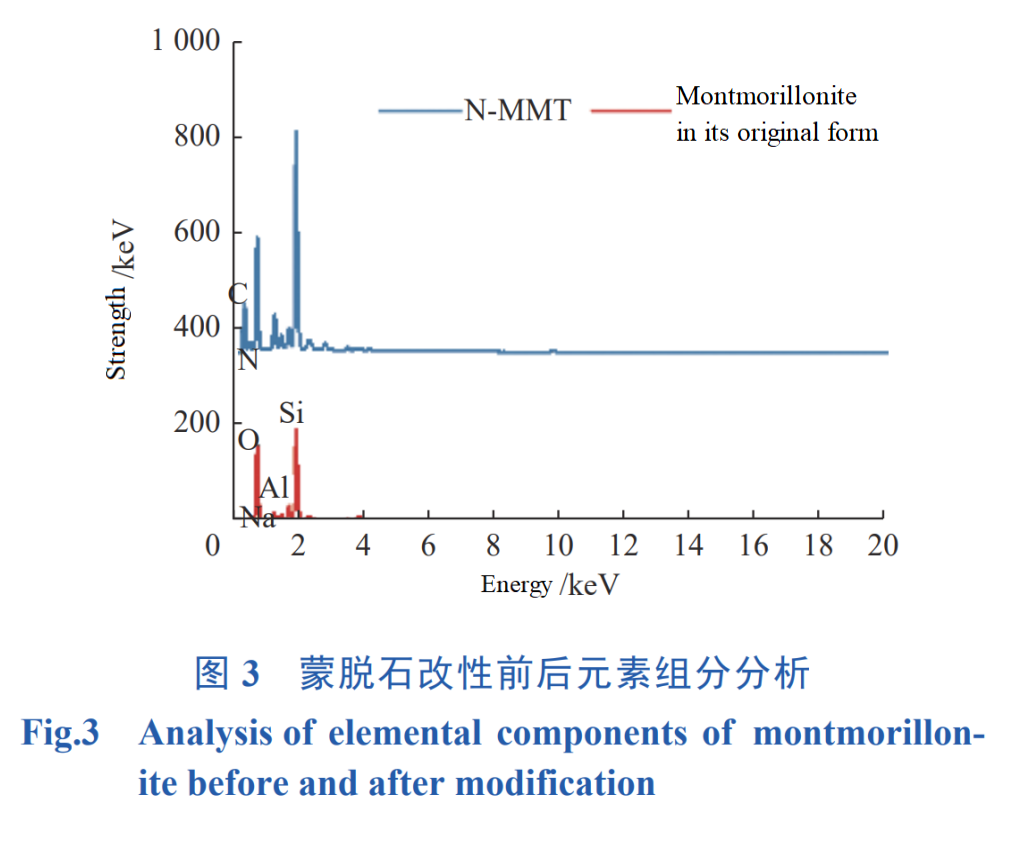

Using anhydrous ethanol as a dispersant, the particle size of montmorillonite samples, low dimensional montmorillonite, and final modified products were analyzed using a Bettersize 2600LD laser particle size analyzer. The results are shown in Figure 4. The average particle size of untreated montmorillonite is 2.65 μm. Compared with the original montmorillonite, the particle size distribution peak of montmorillonite after mechanical chemical exfoliation significantly shifts to the left, with an average particle size of 315nm, indicating that the multi-layer structure has been effectively destroyed and decomposed into low dimensional or even single-layer sheet-like structures, which is conducive to further preparation of nano sealing agents. Compared with the pre modified low dimensional nano montmorillonite particle size distribution, the average particle size increased to 526nm, indicating that the particle size was increased by surface growth of flexible molecular chains.