Nano Toughened Cement Slurry Cementing Technology for Shale Gas Slim-Hole Horizontal Wells(Part 1)

Abstract

In order to improve the cementing quality of shale gas small wellbore horizontal wells, ensure the sealing effect of cement ring fracturing and the integrity after fracturing, nano toughened cement slurry and its supporting technology were studied. A nano toughened cement slurry was developed using fiber composite carbon nanotubes, and the resulting cement paste has the characteristics of low modulus and high tensile strength. Compared with conventional cement stone, the elastic modulus of nano toughened cement stone is reduced by 50.9%, the compressive strength is increased by 28.1%, and the maximum tensile strength can reach 5.2 MPa. At the same time, this article studied the matching three-stage mixing process of carbon nanotubes, which solved the problems of easy entanglement and difficult dispersion of high-dose nanomaterials, and achieved the on-site application of carbon nanotube cement slurry for the first time. The cementing test results of nano toughened cement slurry show that the qualified rate of cementing quality in the horizontal section reaches 98%; The micro seismic monitoring technology was used to evaluate the sealing effect of the nano toughened cement ring. During the fracturing process, the micro seismic event in the designed outer area was 0, indicating that the nano toughened cement ring is well sealed. Research has shown that nano toughened cement slurry can provide technical support for efficient and low-cost development of shale gas.

In recent years, China has made significant breakthroughs in shale gas exploration and development, with proven shale gas reserves exceeding 1×1012 m3 and shale gas production exceeding 200×108 m3, showing a rapid growth trend. The terrestrial shale gas resources in the Ordos Basin are abundant. In order to further improve drilling speed and reduce drilling costs, small hole drilling tests with ϕ152.4 mm drill bits and ϕ114.3 mm casing completion were carried out in the target layer. Compared with the commonly used ϕ215.9mm drill bit and ϕ139.7mm casing completion combination for shale gas horizontal wells, the thickness of the cement sheath is reduced by 50%, and the stress state and failure mode of the cement stone may also undergo significant changes. At the same time, with the rapid development of fracturing technology, long horizontal section+fine cutting fracturing+high-strength transformation has become the main technology for shale gas development. The spacing between sections and clusters has been significantly reduced (minimum 4 meters), which puts higher requirements on the anti damage ability of the cement sheath outside the casing and the establishment of effective inter cluster sealing ability. In addition, existing shale gas horizontal well development practices have shown that the production and safety hazards caused by the failure of the cement ring seal outside the casing after fracturing should also be taken seriously. Therefore, targeted design is required for the cement slurry used to seal shale gas small wellbore horizontal wells.

The study by Su Donghua et al. shows that during fracturing, the cement sheath is prone to tensile failure and mechanical integrity failure. The smaller the thickness of the cement sheath, the higher the demand for tensile strength; Wang Tao and others believe that reducing the elastic modulus of cement can avoid plastic deformation, and the smaller the thickness of the cement sheath, the lower the required elastic modulus; Zhang Chengjin et al. found that after adding fibers to cement slurry, crack extension can be prevented through crack bridging, deflection, or fiber pull-out, improving the deformation ability of cement paste, reducing its elastic modulus, and enhancing its toughness. The maximum reduction in its elastic modulus can reach more than 51.3%; Liu Huiting and others studied the effect of carbon nanotubes on the performance of cement slurry and demonstrated the feasibility of using carbon nanotubes in well cementing. This article is based on fiber cement slurry, compounded with smaller carbon nanotubes, and developed a nano toughened cement slurry with low elastic modulus and high tensile strength. Through the bridging and filling of multi-scale (mainly nano and micro scale) pores, the fracturing sealing effect and integrity of the cement sheath are improved. At the same time, in order to solve the problems of poor dispersion and easy aggregation of carbon nanotubes, a three-level mixing technology has been developed, and the on-site application of carbon nanotube cement slurry has been achieved for the first time at home and abroad.

1. Test Method for Nano Toughened Cement Slurry

1.1 Technical Ideas

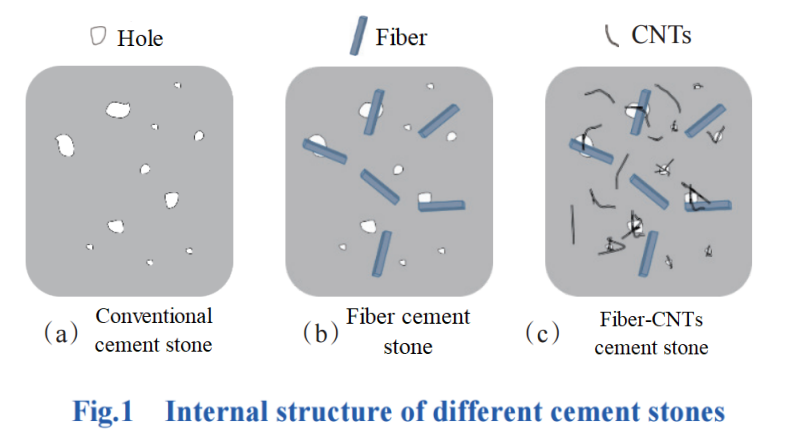

When cement stone is subjected to external loads, its deformation ability is poor and its brittleness is strong. Adding fiber materials such as carbon fiber, brucite fiber, and polypropylene fiber can improve the strain and crack resistance of cement stone. However, the fiber size is large, and its bridging effect on nano and micro sized pores in cement stone is weak. At the same time, when the fiber dosage is high, pumping cement slurry can easily block the pipeline, causing pump blockage. Therefore, it is considered to adopt the method of reducing fiber dosage and compounding nanoscale carbon nanotubes. On the one hand, it enhances the bridging and filling effect of nanoscale and micrometer sized pores, and on the other hand, it strengthens the pores covered by fibers. While reducing the elastic modulus, it improves the macroscopic tensile properties of cement paste. The schematic diagram of the relevant effect is shown in Figure 1 (CNTs are carbon nanotubes in Figure 1).

1.2 Test Materials and Methods

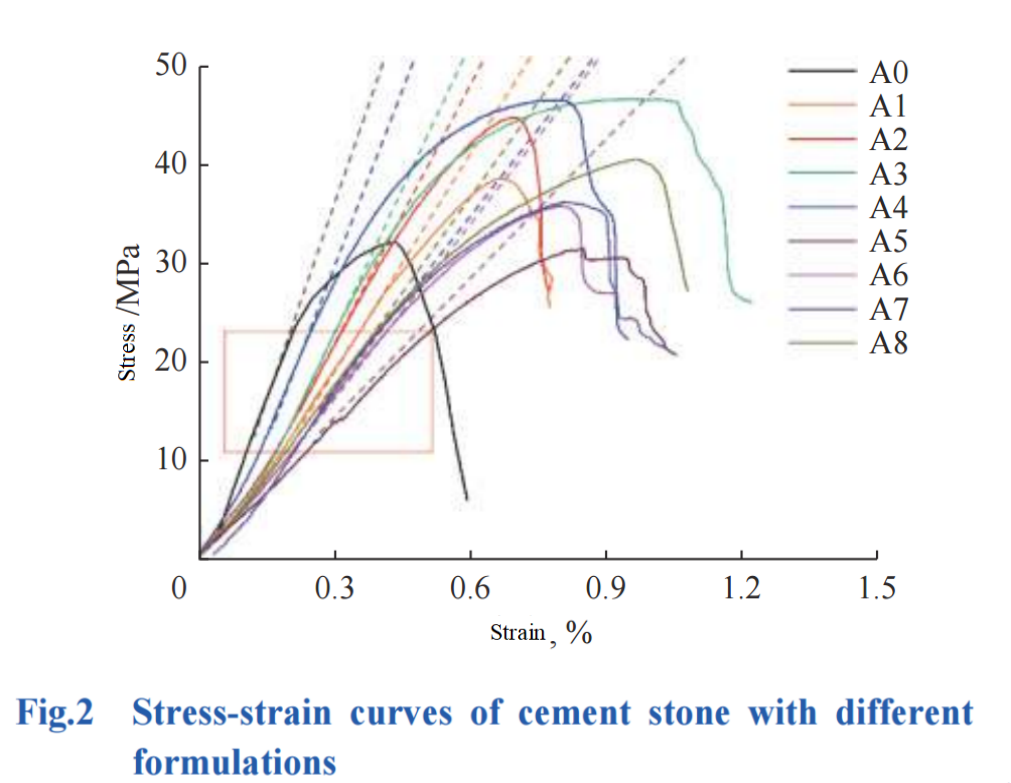

The oil well cement used in the experiment is G-grade cement; Select polypropylene fibers with a length of 5 mm for fiber selection; Carbon nanotubes have a diameter of 40-60 nm and a length of 8-15μm multi-walled carbon nanotubes; Select polymer based fluid loss agents and oil well cement dispersants. Based on the research progress of the above materials, the range of fiber dosage is determined to be 0-1.00%, and the range of carbon nanotube dosage is determined to be 0-0.06%. The dosage of key materials for different formulations of cement slurry is shown in Table 1.

Before preparing cement slurry, carbon nanotubes were dispersed using an ultrasonic disperser, and the aqueous solution of carbon nanotubes was subjected to 320 W power ultrasonic treatment for 30 minutes. The preparation of cement slurry (stone) and the routine performance testing of cement slurry refer to the "Test Method for Oil Well Cement" (GB/T 19139-2012),the elastic modulus and tensile strength of cement stone are tested using the method described in "Shale Gas: Cementing Engineering: Part 2: Technical Requirements and Evaluation Methods for Water Mud" (NB/T 14004.2-2016),the pore size test of cement stone adopts the mercury intrusion method, and the curing conditions for the tested cement stone are 80℃× 20.7 MPa × 28 days.

2. Performance Optimization of Nano Toughened Cement Slurry

2.1 Elastic Modulus Test

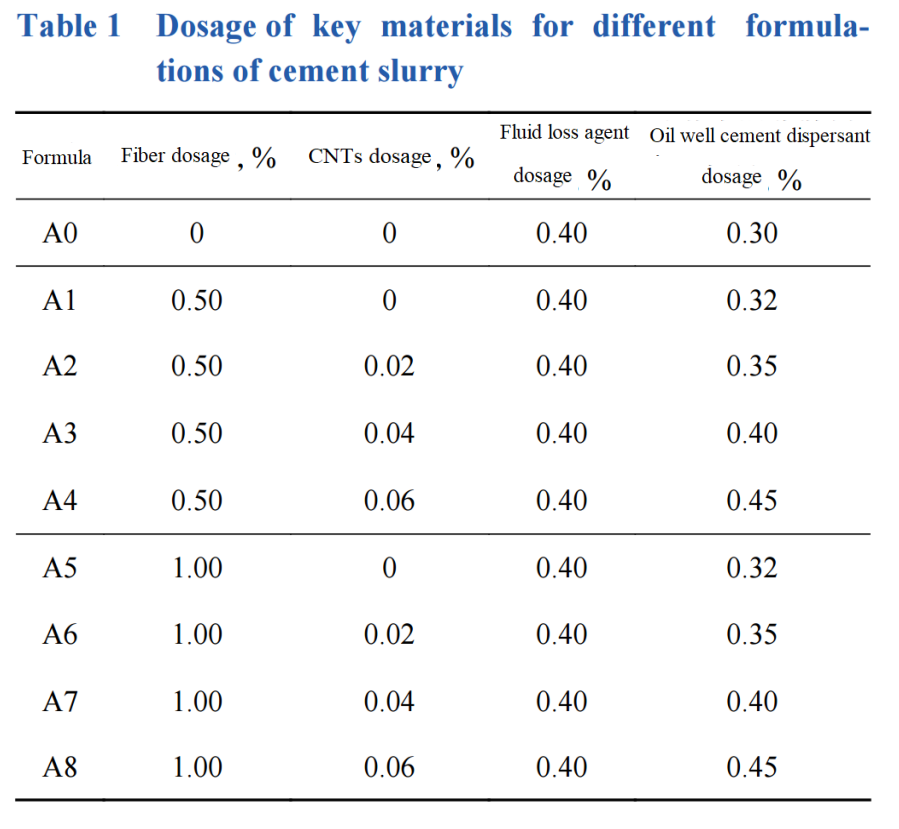

Test the elastic modulus of different cement stone samples, and the stress-strain curve is shown in Figure 2 (in Figure 2, the box represents the value range for elastic modulus calculation, and the dashed line represents the slope of the curve).

From Figure 2, it can be seen that formula A0 cement slurry without fibers and nanotubes has the highest elastic modulus of 12.9 GPa in the formation of cement paste. The time from the elastic stage to the yield stage is the shortest, and the stress decreases rapidly after fracture, showing a characteristic of high brittleness. Formula A5 cement slurry has the highest fiber addition and no carbon nanotubes, resulting in the lowest elastic modulus of cement paste formation. It still has a certain degree of deformation ability after reaching the yield strength. The elastic moduli of cement paste formed by formula A1-A4 are 7.2, 8.8, 9.6, and 11.6 GPa, respectively. This indicates that when the fiber dosage is 0.50%, the elastic modulus of cement paste increases and decreases after mixing with carbon nanotubes, but the ultimate bearing capacity of the matrix also increases and the yield strength increases; The fiber content in formula A5-A8 cement slurry is 1.00%, and the elastic moduli of the formed cement paste are 4.7, 6.1, 6.2, and 6.5 GPa, respectively. Compared with low fiber content cement paste, the elastic modulus is significantly reduced. This is consistent with the research conclusion of Guo Xiaoyang et al., fibers can play a "bridging" role in the matrix, increase strain through "tensioning", and play a role in transmitting and dissipating stress during the stress process, delaying the extension speed of cracks, When subjected to external loads, the stress-strain curve slows down and the elastic modulus decreases. When carbon nanotubes are added to the cement slurry with a high fiber content, the increase in the elastic modulus of the cement paste is relatively small. Its significant advantage is that it significantly increases the differential stress (ultimate bearing capacity when damaged) of the cement paste. The larger the fiber dosage, the better the synergistic effect with carbon nanotubes, and the more significant the effect of improving the differential stress of cement paste. Referring to NB/T 14004.2-2016, the elastic modulus of shale gas fracturing horizontal well cement should be less than 8GPa, and formulas A1, A5, A6, A7, and A8 can meet the requirements.

2.2 Formula Optimization

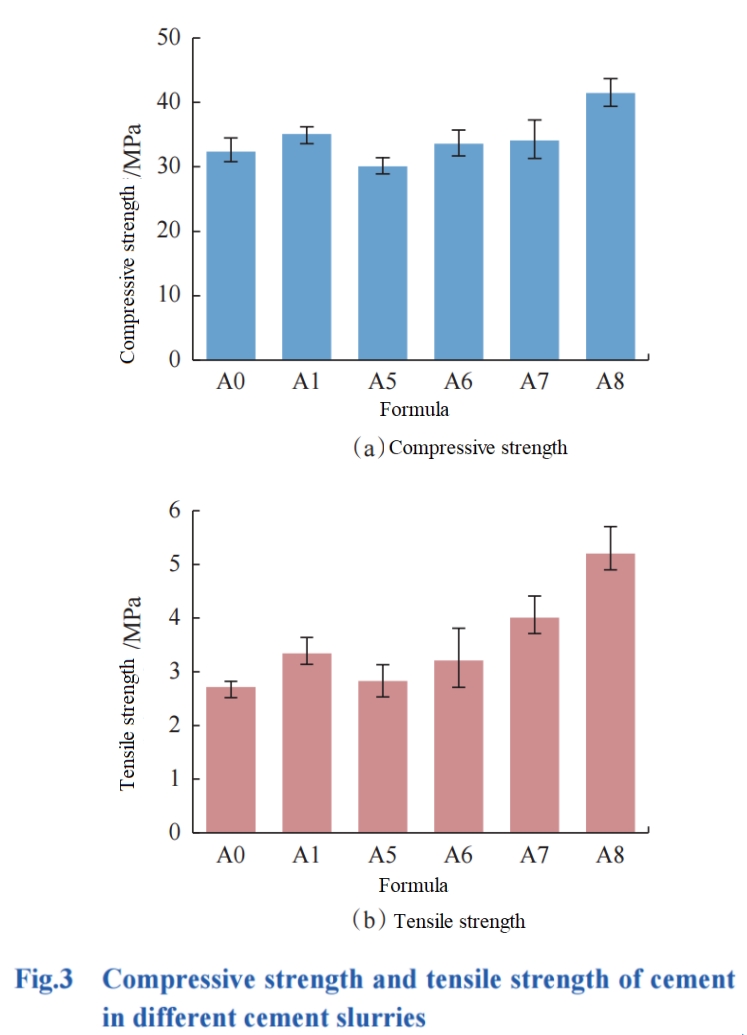

Test the compressive and tensile strength of cement paste formed by formula A1, A5, A6, A7, and A8 cement slurries, and compare them with conventional cement paste (formula A0). The results are shown in Figure 3.

From Figure 3, it can be seen that when the fiber dosage is 0.50% and there are no carbon nanotubes (Formula A1), the compressive strength of cement paste is higher, but its tensile strength is lower, which is not conducive to toughening and crack prevention; When the fiber dosage is increased to 1.00%, without carbon nanotubes (formula A5) and with low dosage of carbon nanotubes (formulas A6 and A7), the tensile strength of cement paste is lower, and there is a certain risk of tensile failure; After compounding 0.06% carbon nanotubes with 1.00% fiber (formula A8), its tensile strength is higher. Analysis suggests that this is mainly due to the combined effect of fibers and carbon nanotubes at a finer scale. The scale of crack bridging has been refined from the micrometer level to the nanometer level, achieving complementary advantages between the two materials and improving the toughness of cement paste. This is a huge advantage of carbon nanotube fiber composite. Therefore, the cement slurry with formula A8 was selected as the cementing cement slurry for the small wellbore horizontal well in this area. Compared with conventional cement stone, the compressive strength of this cement slurry cement stone increased by 28.1%, and the tensile strength reached 5.2 MPa.