Intelligent Optimization of Overall Fracturing for Unconventional Reservoirs(Part 1)

Abstract

The overall fracturing technology achieves one-time well layout, one-time fracture layout, and synchronous production through batch drilling and batch pressing, which is one of the key technologies for the efficient development of unconventional oil and gas reservoirs.The optimization of well spacing and fracture spacing matching is of great significance for improving the overall transformation effect of reservoirs.A three-dimensional geological model was established for a typical block of the Mahu conglomerate reservoir using logging data and fracturing construction parameters through the geological engineering integrated Petrel platform; A heterogeneous refined four well platform hydraulic fracturing production capacity prediction model was established based on CMG reservoir numerical simulator and local logarithmic grid refinement method; By combining particle swarm optimization algorithm and differential evolution algorithm, the well spacing and fracture spacing of the four well platform were optimized with the production capacity of the well group as the objective function, achieving seven dimensional parameter synchronous optimization.The optimized well cluster production capacity has increased by 16.3% compared to the actual production data on site; The stable production cycle of a single well on the four well platform is longer, and the rate of production decline is slower; The pore pressure field has a wider range of influence, further promoting the improvement of oil well productivity. The research results have laid the model and method foundation for optimizing the overall fracturing scheme of unconventional oil and gas reservoirs.

The optimization of well spacing and fracture spacing matching in the overall development of unconventional reservoirs is a multidimensional and complex problem, and a reasonable horizontal well deployment plan is crucial for stimulating reservoir production potential and improving development efficiency.Researchers at home and abroad have conducted a series of optimization studies based on numerical simulation methods for overall fracturing.Zhou Dehua et al. proposed a numerical simulation method based on an embedded discrete fracture model, and used the Fuling Jiangdong block as an example to comprehensively analyze the impact of fracturing technology, inter well interference, and other factors on well productivity using orthogonal experimental methods. They evaluated the three-dimensional development effect and proposed corresponding plans for stable and increased production.Mao Yingxiong took the East II well area of Niuquan Lake oil field as an example and established a numerical simulation model for overall hydraulic fracturing of horizontal wells based on the overall PEBI grid method. He studied the matching degree of oil and water well fractures in the horizontal well group and further optimized the fracture half length and diversion capacity of the well group through orthogonal experimental method.Therefore, the optimization approach for overall fracturing is based on actual geological and production data, establishing a numerical model of the reservoir, selecting typical well groups for production capacity prediction, and optimizing the development plan with better estimated production.However, there are many uncertain factors in the geological conditions of the reservoir, and the orthogonal experimental optimization method requires repeated operation of the reservoir simulation software, which is time-consuming and difficult to efficiently and quickly obtain the optimal overall deployment plan.

In recent years, domestic and foreign researchers have used a combination of numerical simulation and optimization algorithms to iteratively obtain the optimal overall fracturing deployment plan.Xu et al. combined the discrete crack model with an automatic search algorithm to optimize variables to obtain the highest net present value, and also compared the performance of different algorithms.Wang et al. combined fracturing simulation, reservoir simulation, geomechanical calculation, and machine learning to construct a new completion plan based on the initial case, forming a complete workflow for generating optimal well spacing.The optimization research of multi well platforms has been preliminarily applied in the field, but well location optimization algorithms are mostly global optimization algorithms, such as differential evolution algorithm (DE), genetic algorithm (GA), particle swarm optimization algorithm (PSO), simulated annealing algorithm (SA), etc.Differential evolution algorithm has the advantages of simple principle and strong robustness, but its convergence speed is slow and errors are prone to occur in high-dimensional problem operations;Genetic algorithm has strong global search ability, strong parallelism, and good interpretability, but it is easy to converge to local optimal solutions and has a long running time, making it unsuitable for high-dimensional problems;Particle swarm optimization algorithm does not require gradient information, has fast convergence speed, and a wide range of applications. However, the performance of this algorithm is affected by parameter selection and adjustment, and requires certain experience and experimental tuning. Moreover, this algorithm has a strong dependence on initial solutions, and poor initial solutions will lead to poor optimization results;The simulated annealing algorithm has strong global search capability and is suitable for high-dimensional parameter optimization problems. However, its performance is greatly affected by parameter selection and adjustment, and the search process takes a long time, especially when dealing with feasibility constraints for complex problems.

The overall fracturing optimization technology for reservoirs has been widely applied in China, but there are significant differences in reservoir conditions, and a systematic overall fracturing scheme optimization method has not yet been formed.The current overall fracturing parameter optimization technology has the following problems: ① It cannot comprehensively consider the design of fractures and well locations, and can only obtain local optimal solutions;② The simulation time for oil reservoirs is too long, especially for larger reservoir models. In order to reduce the simulation time, simple models are used instead, which are not accurate enough;③ There are few variables in the optimization process, and there are many fixed variables, which cannot comprehensively consider the mutual influence between various parameters of the reservoir;④ Lack of methods for platform well development and optimization based on on-site datasets.

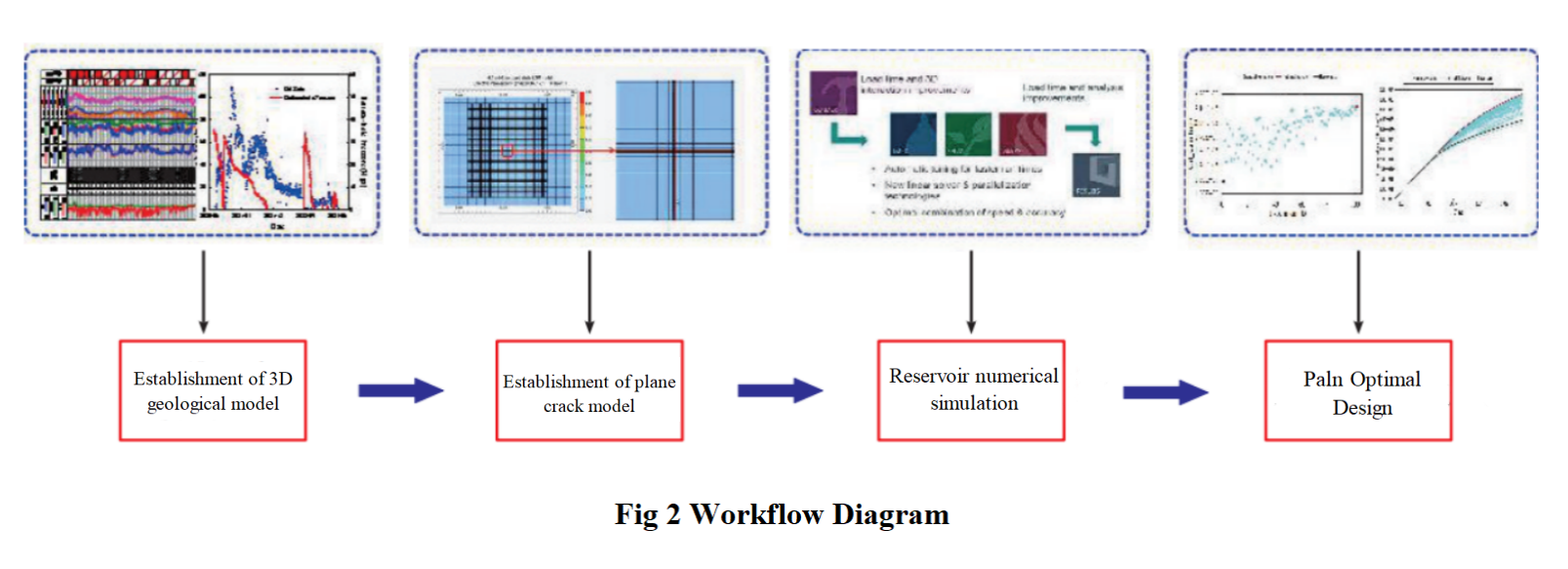

This article establishes a fine geological model based on the integrated Petrel platform of geological engineering, and establishes a four well platform productivity prediction model based on the CMG reservoir numerical simulator and local logarithmic grid refinement method.Using particle swarm optimization algorithm and differential evolution algorithm, the seven dimensional parameters of well spacing (WS, 1, WS, 2, WS, 3) and fracture spacing (fS, 1, fS, 2, fS, 3, fS, 4) of the four well platform were optimized with well group productivity as the objective function. The performance of the two optimization algorithms was further compared, and the optimal well spacing and fracture spacing scheme was selected to improve the overall transformation effect of three-dimensional development.

1. Optimization Method for Three-dimensional Development of Platform Wells

1.1 Advantages of Three-dimensional Development

As an emerging unconventional oil and gas reservoir development technology, platform well three-dimensional development has many advantages compared to traditional single well development.

1) Reduce surface occupation area and environmental impact. The three-dimensional development technology of platform wells utilizes the same platform to simultaneously drill multiple wells, reducing the number and footprint of drilling equipment construction on the surface. Compared to traditional single well development, platform well three-dimensional development can reduce land occupation, water resource consumption, and minimize damage to the original ecological environment.

2) Improve development efficiency and reduce costs. The three-dimensional development technology of platform wells can achieve one-time well layout, one-time seam layout, and synchronous production. Through batch construction and operation, the unit cost of drilling and fracturing operations can be reduced. In addition, drilling and production operations of multiple wells can be carried out simultaneously during the development process to improve development efficiency.

3) Increase reservoir utilization and improve recovery efficiency. The three-dimensional development technology of platform wells can fully utilize reservoir space, increase reservoir mobilization, and improve recovery efficiency through staggered fracturing and multi-layer three-dimensional zipper fracturing. Compared with traditional single well development, platform well three-dimensional development can more accurately control fracturing and injection production operations, thereby maximizing reservoir potential.

4) Improve the level of oil and gas exploration and development. The three-dimensional development technology of platform wells can better understand the characteristics and properties of reservoirs, optimize fracturing schemes, and improve the level of oil and gas exploration and development through the study of the spatiotemporal evolution of three-dimensional stress fields.Figure 1 is a schematic diagram of the three-dimensional development of a platform well. By designing the spacing between fractures fS, 1 and well spacing WS, 1 reasonably, the affected area of the pore pressure field is increased, thereby increasing the formation pressure difference and making it easier for oil and gas to flow and be collected, resulting in a solution that can maximize the potential of the reservoir.

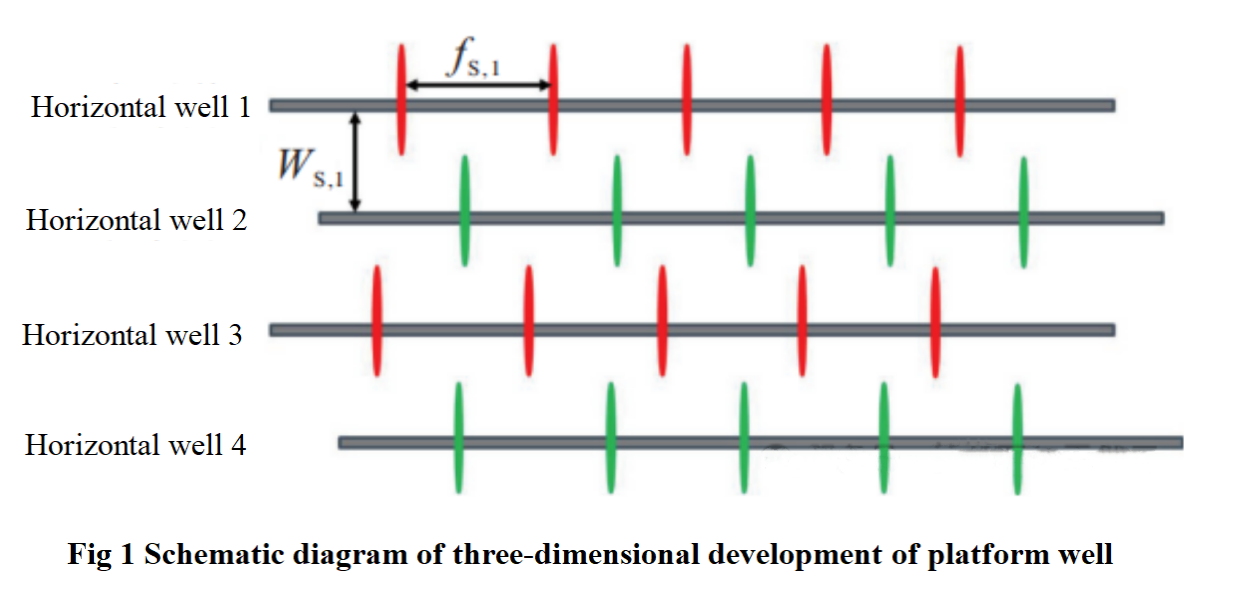

1.2 Workflow of Stereoscopic Development

This article adopts the multi platform fusion method (Petrel+CMG) for the first time, combined with intelligent optimization algorithms, to achieve overall optimization of fracture parameters in heterogeneous models of flat wells.Using Petrel modeling to characterize heterogeneous attributes of the model; Using CMG-GEM component simulation to simulate multi fracture seepage in platform wells; Utilizing automatic search algorithms to achieve synchronous optimization of high-dimensional parameters of platform wells, in order to obtain the best matching overall design parameters.As shown in Figure 2, firstly, based on the integrated geological engineering software Petrel, a three-dimensional fine geological model is established by combining logging data and fracturing construction parameters; Secondly, the 3D geological fracture model is imported into CMG and subjected to mesh refinement processing. A planar fracture model with local mesh refinement is used to simulate fluid flow inside and around the fracture; Again, reservoir simulation is conducted in the GEM module of CMG as the initial optimization plan; Finally, combining optimization algorithms, the CEM reservoir numerical simulator in CMG is called to find the optimal solution.