Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

Abstract

In response to the serious blockage caused by the gradual precipitation, aggregation, and sedimentation of asphaltene with decreasing temperature during the wellbore lifting process in Tahe Oilfield, the steel wire mesh dissolution method was used to develop and evaluate asphalt dispersants.By characterizing and analyzing the three components, elemental composition, and scanning electron microscopy (SEM) of wellbore sediments, it was determined that the main component of wellbore sediments in Tahe Oilfield is asphaltene.Based on the principle of similar solubility, a highly efficient dispersant LYH-1 (aromatic solvent LY+1.0% n-pentanol+1.0% nonylphenol+0.2% petroleum sulfonate) for dissolving asphalt has been developed.Soak the asphalt sediment in asphalt dispersant LYH-1 at 50 ℃ in a water bath and let it react for 4 hours. The dissolution rate of 5 g of asphalt dispersant LYH-1 on 1 g of asphalt sediment is as high as 97%, and it does not aggregate after long-term storage. It has good stability and universality.By studying the mechanism of action of the highly efficient asphalt dispersant LYH-1 on asphalt, it was demonstrated that it mainly forms a stable system with asphalt deposits through hydrogen bonding and π - π interactions, reducing the particle size of asphalt aggregates and stabilizing them in solution, hindering further coagulation and deposition of asphalt.The research results indicate that LYH-1 is a novel high-performance asphalt dispersant that can effectively prevent blockages in oil wells and surface pipelines while reducing production costs, achieving the goal of increasing production and improving the development efficiency of heavy oil reservoirs.

Global heavy oil reserves are abundant and have received widespread attention in recent years, but their extraction faces many challenges. Due to the high content of gum and asphaltene in heavy oil, as well as the low amount of light fractions, it has the characteristics of high viscosity and high density. In addition, changes in external factors can cause the asphaltene in heavy oil to become unstable and accumulate, blocking the flow path and hindering the flow of crude oil during oil and gas extraction, thereby reducing the recovery rate of the reservoir.Researchers at home and abroad use air foam flooding, fire flooding, steam flooding, in-situ catalytic upgrading and other technologies to reduce viscosity and improve oil recovery. Tahe Oilfield contains a large amount of heavy oil, with a asphaltene content of over 40%. The related asphaltene deposition problems encountered in heavy oil extraction are even more serious, which have a serious impact on oilfield production and economic benefits.

In order to solve the problem of asphaltene deposition during heavy oil extraction, it is necessary to add dispersants to the crude oil. The dispersants wrap around the asphalt particles to keep the asphalt aggregates stable in the colloidal suspension.However, the dispersants currently available on the market have strong specificity, and their effectiveness may vary depending on the quality of the oil, making them not universally applicable to major oil field operations in China.The relative molecular weight of asphaltene in crude oil is the heaviest and it has extremely strong polarity.According to the principle of similar solubility, polar organic solvents containing polar or aromatic groups can interact with asphaltene molecules, dispersing asphaltene particles by reducing their size and coagulation behavior, ensuring that asphaltene particles remain suspended in crude oil.The higher the content of heteroatoms in asphalt, the stronger its interaction force, and the higher the degree of intermolecular binding. Asphalt is more likely to aggregate and precipitate. In addition, most efficient asphalt dispersants are organic chlorine solvents that are prohibited from use in the petroleum industry and are expensive. It is urgent to develop an efficient asphalt dispersant that does not contain organic chlorine.

This article focuses on the problem of asphalt enrichment blocking oil wells in Tahe Oilfield. Experiments were conducted to screen a single solvent and optimize the solvent formula. A new efficient dispersant LYH-1 was developed, and a new method for accurately measuring the solubility of asphalt dispersants was established.Dispersant LYH-1 can enable asphaltene to exist in a stable dispersed state in crude oil, preventing reservoir pores and pipeline blockages caused by self association, which is of great significance for controlling the stable dispersed state of asphaltene in crude oil extraction and processing.

1. Experimental section

1.1 Experimental Materials and Instruments

The experimental raw materials include: sediments from Tahe Ha Yi Lian and Ha Liu Lian;Xylene, aromatic solvent LY, fatty acid methyl ester, dibutyl phthalate, ε - caprolactone, butyl acetate, ethylene glycol ethyl ether acetate, propylene glycol butyl ether, triethylene glycol monobutyl ether, calcium alkyl salicylate, N-N-N-di (hydroxyethyl) cocoamide, nonylphenol, 1,6-hexanediol, n-pentanol, n-octanol, and ethylene glycol butyl ether are all analytically pure;Mobil S150 solvent oil (S150), Mobil S180 solvent oil (S180), C9 aromatics, 95% anhydrous ethanol, octanol polyoxyethylene ether (op-4), alkylphenol polyoxyethylene ether (op-10), petroleum sulfonate, sorbitan monostearate (span 60), sorbitan oleate (span 80), and fatty alcohol polyoxyethylene ether (AEO-9) are all industrial products.

1.2 Experimental Instruments and Parameter Settings

① Scanning electron microscopy (SEM) analysis. Acceleration voltage: 15.0 KV; working distance: 8.0~8.9 mm; gold spraying.

② Elemental composition (EA) analysis. CHN mode conditions: 980℃, acquisition time of 300s; S mode conditions: 980℃, acquisition time of 500s; O mode conditions: 1070℃, acquisition time of 500s.

③ AMG EVOSFL inverted fluorescence microscope analysis without eyepiece. Power supply: 220 V (AC); Environmental temperature: 10~35℃; Relative humidity: 20%~85%.

④ BT-9300LD dry wet laser particle size analyzer analysis. The dispersion medium is water, with a light shielding rate of 1.03%, a material refractive index of 1.6300 00+0.1000 00i, and a medium refractive index of 1.333. Collect the data three times and take the average value.

1.3 Construction of Evaluation Method for Asphalt Dispersants

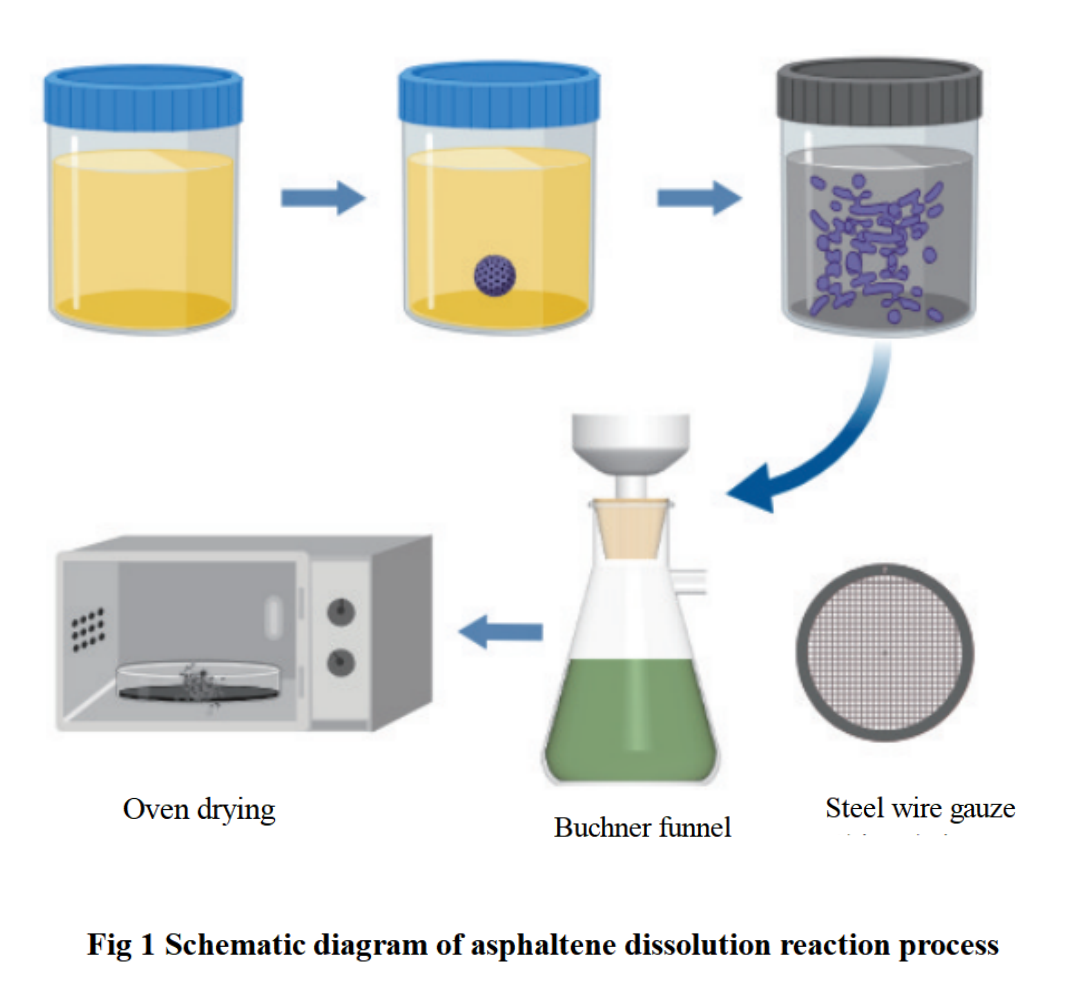

At present, there is no established evaluation standard for asphalt dispersants in China. In order to meet the requirements of rapid evaluation of the performance of asphalt dispersants on oilfield sites, this article constructs a new method for efficiently and accurately determining the solubility rate of asphalt dispersants.The specific operation is as follows: Make 1 g small balls of Ha Yi Lian asphalt sediment, add 5 g of dispersant, and dissolve them in a 30℃ constant temperature test chamber for 120 minutes; Filter the 120 mesh steel wire mesh, clean the remaining sediment at the bottom of the bottle with anhydrous ethanol, and dry it in a 50℃ oven for 6 hours. Weigh and record the remaining insoluble matter mass. The ratio of the dissolved sediment mass to the initial sediment mass is the dissolution rate of the sediment.The dissolution reaction process is shown in Figure 1. Using the difference method to compare the states of various dispersants before and after treatment of asphalt deposits, and selecting the dispersant with good dissolution effect.

1.4 Separation of Asphalt Sediments in Tahe

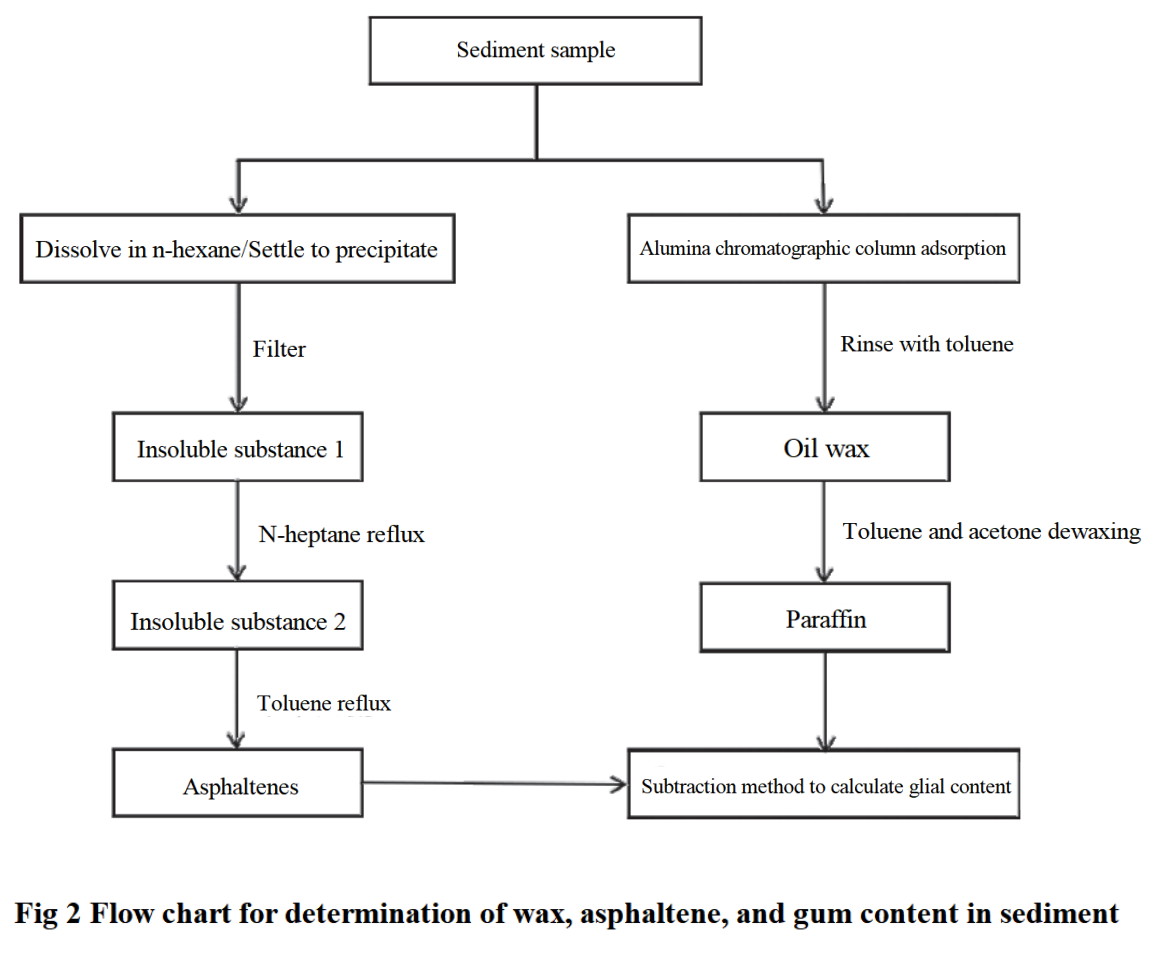

The separation of asphaltene sediment refers to SY/T 7550-2004 "Determination of wax, gum, and asphaltene content in crude oil".Dissolve a sediment sample in n-heptane, filter out the insoluble material, reflux with n-heptane to remove paraffin and gum from the insoluble material, then extract the asphaltene with toluene and dissolve it again to calculate the asphaltene content.In addition, one sample was subjected to alumina column chromatography to remove resin, and then mixed with toluene acetone (1:1) for dewaxing treatment. The wax component in the sample was determined by freezing crystallization method. Use the difference method to analyze the sample and determine the gum content in the sample. The measurement process is shown in Figure 2.

2. Results and Discussion

2.1 Characterization Analysis

2.1.1 Analysis of Chemical Components in Sediments

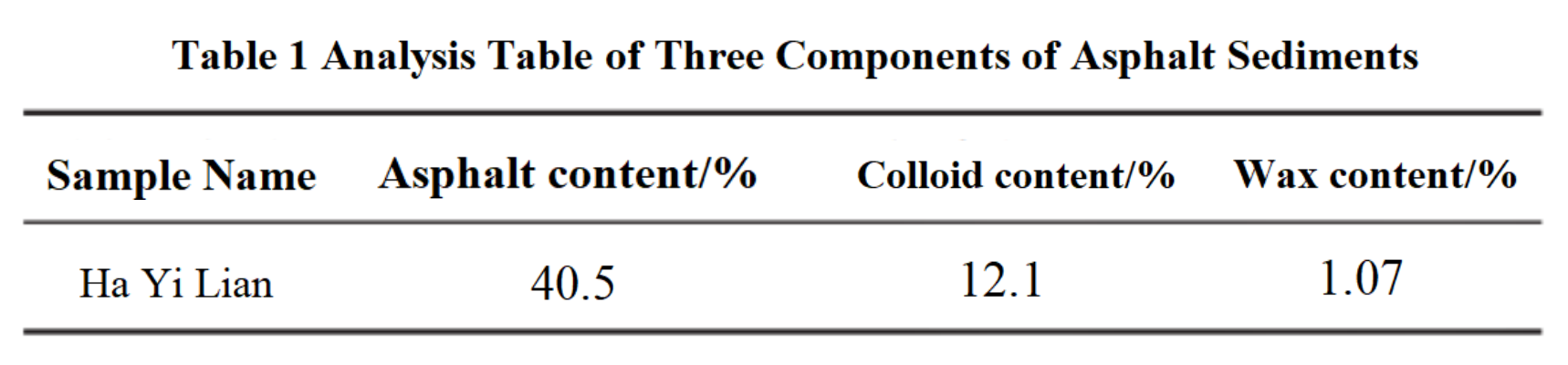

Table 1 shows the results of the determination of three components in the sediment of Ha Yi Lian.

The sediment in the Ha Yi Lian Formation contains 40.5% asphaltene, 12.1% resin, and 1.07% paraffin, with asphaltene being the main component.

2.1.2 Analysis of Asphalt Element Composition

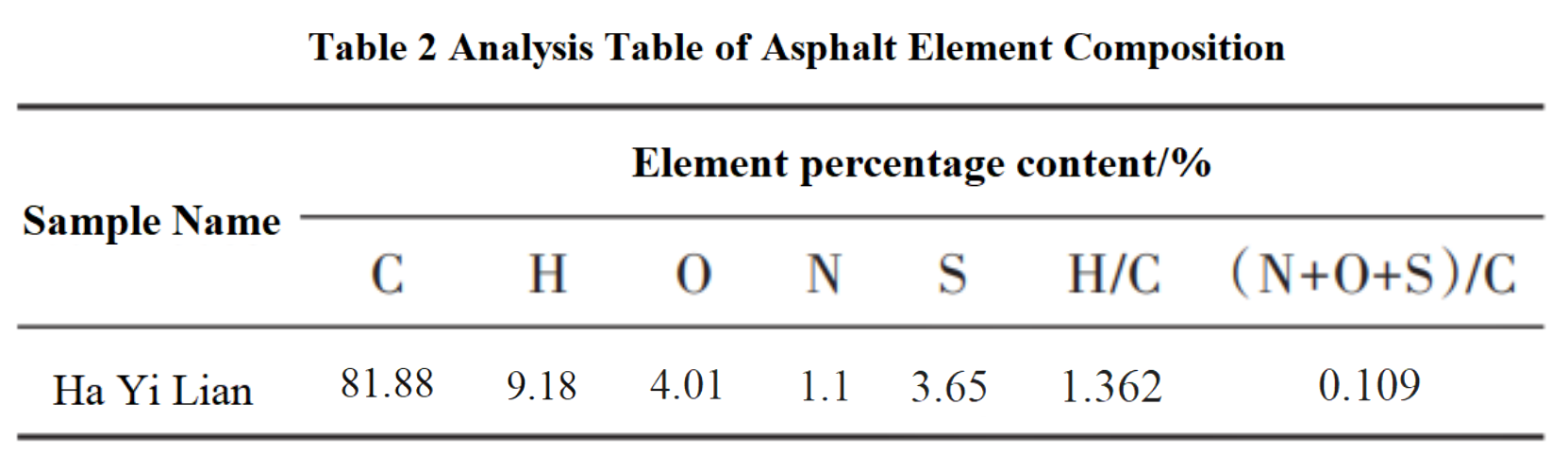

The elemental composition of asphaltene extracted from the sediment of Ha Yi Lian was tested to determine the elemental content in asphaltene. The results are shown in Table 2.

This asphalt contains a significant amount of heteroatoms (O, S, N), with a heteroatom content of O>S>N. The heteroatoms in asphalt can generate strong cohesive forces through charge transfer, hydrogen bonding, dipole forces, and other interactions, which easily lead to molecular aggregation and aggregation, resulting in layered stacking and the deposition of asphalt.The hydrogen to carbon ratio (H/C) of asphaltene plays an inevitable role in its aggregation behavior, and a lower H/C ratio enhances the tendency of asphaltene aggregation. The higher the content of heteroatoms and sulfur in asphalt, the more polar groups there are in asphalt, that is, the higher the ratio of heteroatoms to carbon atoms [(N+O+S)/C], and the easier it is to adsorb at the interface.The H/C ratio in Ha Yi Lian asphalt is very low and the sulfur content is high, indicating that the asphalt has a high degree of condensation and has a high degree of unsaturation such as cyclic and aromatic structures, making it easier for asphalt to aggregate on the wellbore.