Deep Learning based Method for Identifying Pipeline Magnetic Leakage Anomaly Data (Part 1)

Abstract

Pipeline magnetic leakage internal detection technology plays an important role in the field of non-destructive testing of long-distance oil and gas pipelines.In actual operation, the data collected by pipeline detectors inevitably contains abnormal data. Identifying abnormal data will be one of the important criteria for accurately evaluating pipeline performance and a key basis for determining whether the detection equipment is working properly.A lightweight pipeline magnetic leakage anomaly data recognition method based on one-dimensional convolutional neural network (1D-CNN) is proposed to address the current situation of large detection data volume, low efficiency of traditional manual interpretation, and difficulty in meeting industrial needs;Divide the collected magnetic flux leakage data into multiple sampling point sequences along the radial, axial, and circumferential directions, and establish a dataset using the abnormal conditions of the magnetic flux leakage data as labels.Directly taking one-dimensional signals as model inputs, using Convolutional Neural Network (CNN) to automatically extract feature information of magnetic leakage anomaly data, introducing Batch Normalization Layer (BatchNorm) and optimized Dropout Regularization Method to iteratively train and evaluate the model, achieving the recognition of anomalies in magnetic leakage detection data.The results show that this method has high recognition accuracy. When the Dropout ratio is 0.3, the recall rate, accuracy, and precision can all reach over 96%. It has the advantage of batch processing data and can be applied to identify abnormal situations in pipeline magnetic leakage data.The deep learning based pipeline magnetic leakage anomaly data recognition method provides an efficient solution for anomaly data recognition, which can fully explore the important features of magnetic leakage data. The experimental results further confirm the accuracy and effectiveness of the model, and it has broad application prospects.

Long distance oil and gas pipelines are laid in complex natural environments and are susceptible to leakage accidents due to external factors such as construction damage, electrochemical corrosion, and geological disasters. In order to reduce pipeline operational risks, regular inspections should be conducted.Magnetic flux leakage internal detection technology is currently the most widely used detection technique.During the process of collecting pipeline magnetic flux leakage data, abnormal data is mixed in the collected magnetic flux leakage data due to factors such as surrounding environment and detection device failures (such as sensor damage, poor line contact, etc.).These abnormal data not only fail to reflect the true situation of the pipeline, but also interfere with the normal data in the pipeline, directly affecting the evaluation of the overall pipeline performance.Therefore, the identification of pipeline magnetic leakage anomaly data is crucial for data analysis and processing.Therefore, the identification of pipeline magnetic leakage anomaly data is crucial for data analysis and processing.Aljameel et al. compared the recognition ability of six models, including random forest, on outliers using machine learning algorithms.Chen et al. proposed the Single Class Support Vector Machine (OCSVM) algorithm, which learns normal samples of oil pipelines to screen for true pipeline leakage anomalies.Cao Hui et al. proposed a wavelet transform based magnetic leakage anomaly edge detection algorithm based on data fusion to address the unclear abnormal edges caused by noise in magnetic leakage internal detection.Dong Ze et al. proposed an outlier detection method that combines signal decomposition methods with density algorithms. The wavelet transform method is used to extract the running trend of time series, and then the local outlier factor method (LOF) is used to obtain outliers.Emerging deep learning algorithms provide new ideas for efficient processing of big data, especially convolutional neural networks (CNN), which have performed well in fields such as image classification and recognition.Research by Tan Zhen and Zhang Ruicheng found that CNN models have excellent classification performance in pipeline detection, overcoming the limitations of traditional backpropagation (BP) neural networks in pre extracting data feature information and significantly improving the reliability of detection.Yuksel and Cui Guoning proposed YOLOV5 and CNN models respectively to identify and quantify pipeline defects.Shen and Malashin introduced Dropout regularization method in the pipeline corrosion classification CNN model to improve the model's corrosion detection capability.Most deep learning models reshape one-dimensional signals into image form as input, and the powerful feature extraction ability of CNN for one-dimensional signals has not been fully utilized, and there is still some human intervention.

This article proposes a lightweight model based on one-dimensional convolutional neural network for identifying magnetic leakage anomaly data in oil and gas pipelines; Inputting one-dimensional data into the model, introducing batch normalization layers and optimizing Dropout regularization methods to enhance the model's feature extraction capability.In the production of the dataset and optimization of model parameters, the characteristics of magnetic flux leakage data are fully integrated to achieve higher compatibility between the two. Through experimental analysis and evaluation, establish a model for identifying magnetic leakage anomaly data, providing application references for subsequent magnetic leakage data analysis.

1. Pipeline Magnetic Leakage Internal Inspection

1.1 Data Structure of Magnetic Leakage Internal Detection

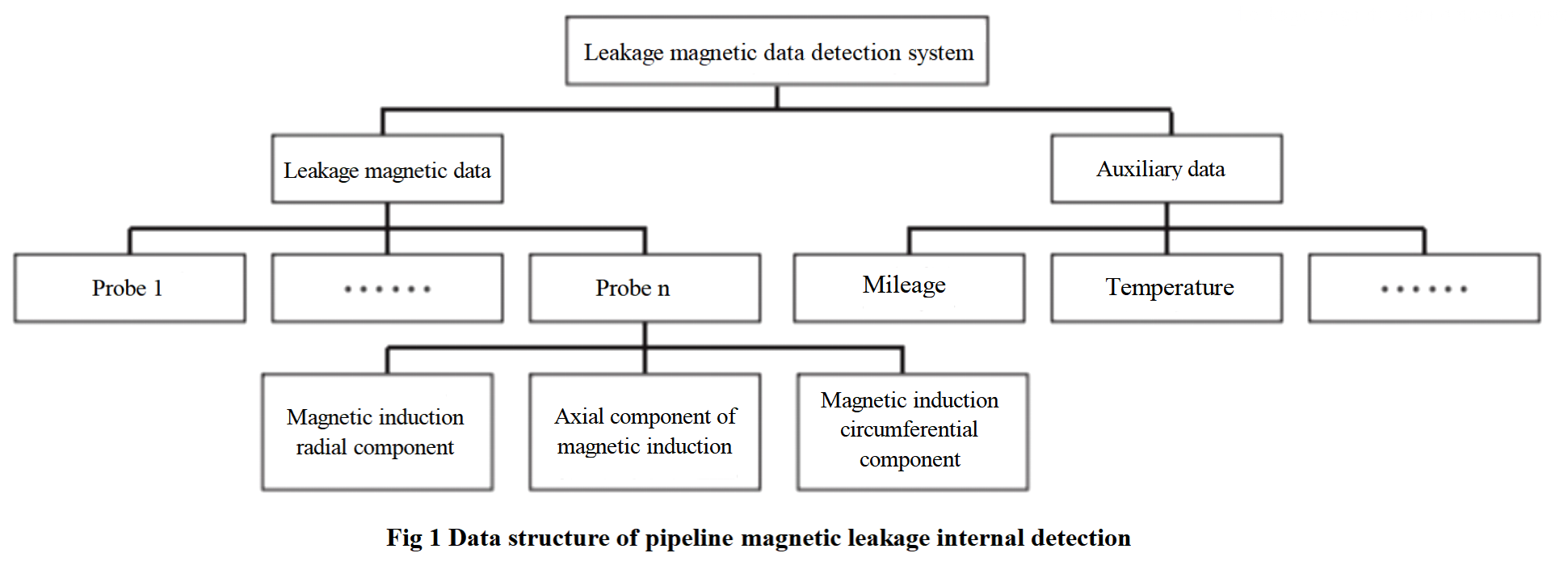

Pipeline magnetic leakage internal detection is to magnetize the pipeline by applying an external magnetic field to the pipeline detector.If there are no defects in the pipe wall, the magnetic field lines will be closed inside the pipe wall; If a defect is encountered on the pipe wall, magnetic field lines will penetrate through the pipe wall and generate a leakage magnetic field.The leakage magnetic field is detected by a probe closely attached to the pipe wall on the detector, processed through filtering and other processes, and then transmitted to the computer for storage (Figure 1).

The main stored data includes radial, axial, and circumferential leakage magnetic data and auxiliary information, which mainly includes mileage, ambient temperature, and pipeline related configuration file information. The leakage magnetic data is closed in a circular shape in the column direction and extends approximately infinitely in the row direction.

1.2 Abnormal Features

1.2.1 Normal Data

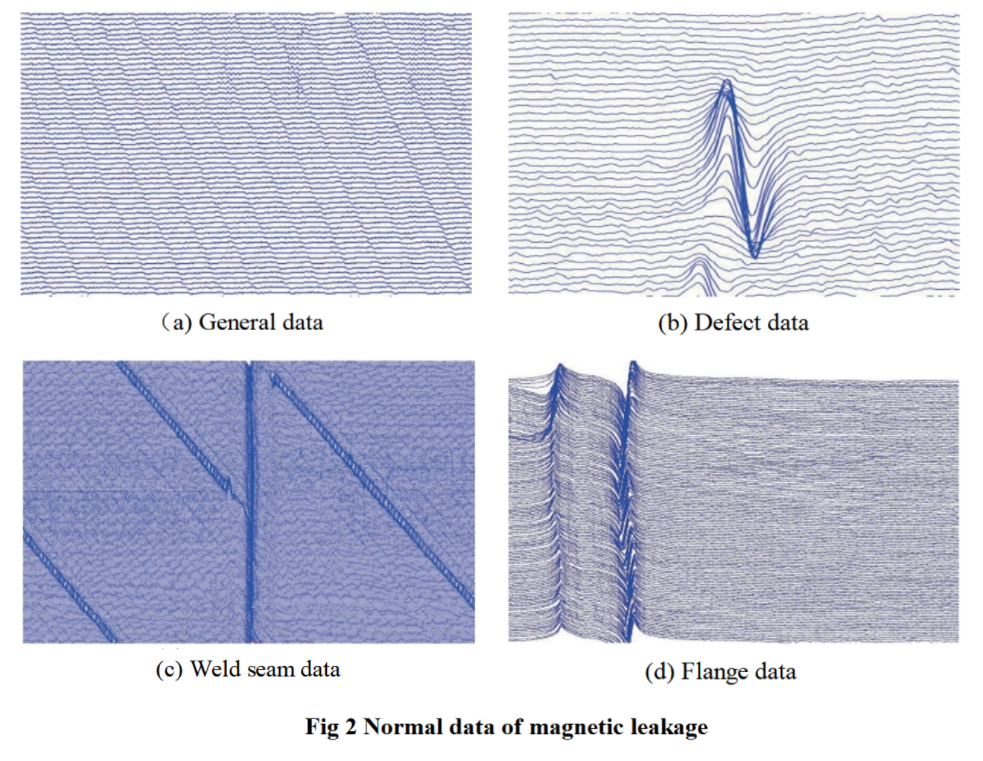

The problem of identifying abnormal data is a binary classification problem, which divides data into normal and abnormal classes.The data that can reflect the true situation of the pipeline is collectively referred to as normal data, such as regular data, defect data, weld data, and flange data, all of which are considered normal data (Figure 2).Defect data can reveal information such as cracks and corrosion in pipelines; Weld seam data and flange data can indicate the component information of the pipeline.

1.2.2 Abnormal Data

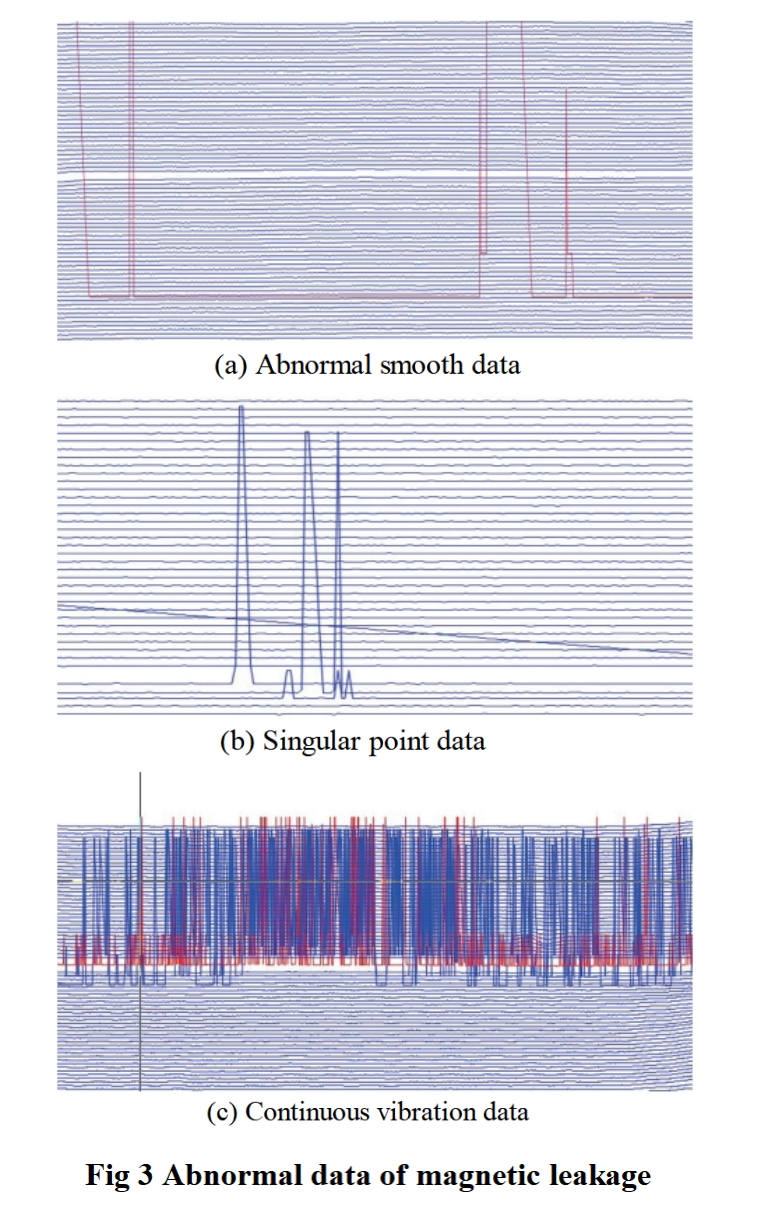

During the process of pipeline magnetic leakage internal inspection, the collected magnetic leakage data often contains abnormal data that cannot effectively characterize the actual state of the pipeline. The common types include three (Figure 3).

Abnormal smooth data (Figure 3a) may be caused by changes in the ambient temperature around the pipeline and changes in the flow velocity of substances inside the pipeline, characterized by the amplitude of continuous sampling point data remaining unchanged and significantly deviating from the baseline value;The singular point data (Figure 3b) is characterized by significant maximum or minimum values appearing locally in individual sampling point data;Continuous vibration data (Figure 3c) may be caused by poor internal contact of the sensor, manifested as a sudden and significant increase or decrease in the amplitude of the continuous sequence sampling point data on a certain channel, forming a pulse like vibration signal with intense intensity.

Compared to normal data that is smooth and regular, abnormal data often comes with randomness and irregularity.Defect data with strong randomness is also very different from abnormal data. Defect data often has the same trend of change in adjacent multiple channels, with obvious peaks and valleys, and smoother signals; Abnormal data often occurs in a single channel, and the signal is more abrupt and sharp, with a longer range of occurrence.Due to the high degree of irregularity in abnormal data, it has a wide variety of types. Therefore, this study adopts a holistic recognition method to detect abnormal data.

2. Establishment of One-dimensional Convolutional Neural Network Model

2.1 Convolutional Neural Networks

Convolutional neural networks have evolved from multi-layer perceptrons (MLPs) and are a variant of neural networks.Unlike traditional artificial neural networks (ANN), it is able to integrate feature extraction and classification tasks into one entity, which is a key advantage in significantly improving classification performance. Convolutional layers automatically obtain input data features and gradually achieve data feature learning through layer by layer stacking. They have strong parallel processing and fault tolerance capabilities, and can fully realize the learning of leakage magnetic data features.