Current Status and Trends of Deepwater Oil and Gas Drilling Technology and Equipment Development(Part 2)

2.2.2 Current Situation of Deepwater Oil and Gas Drilling Equipment in China

At present, China's deepwater drilling engineering equipment is in the early stage of development.As of 2018, China has built 244 fixed platforms, 13 floating production, storage and transportation devices, and 370 submarine pipelines with a total length of 6725 kilometers in the sea area. It has the ability to drill, develop, construct, and maintain conventional oil and gas fields within a water depth of 300 meters. With the advancement of oil and gas exploration and development towards deep water, the "Offshore Oil 981" semi submersible platform with a depth of 1500 meters has been built, and large deepwater engineering equipment such as the "Blue Whale I" and "Blue Whale II" semi submersible platforms have been built (Figure 4), filling the domestic gap and possessing the "deepwater fleet" for independent development and construction of deepwater oil and gas fields.

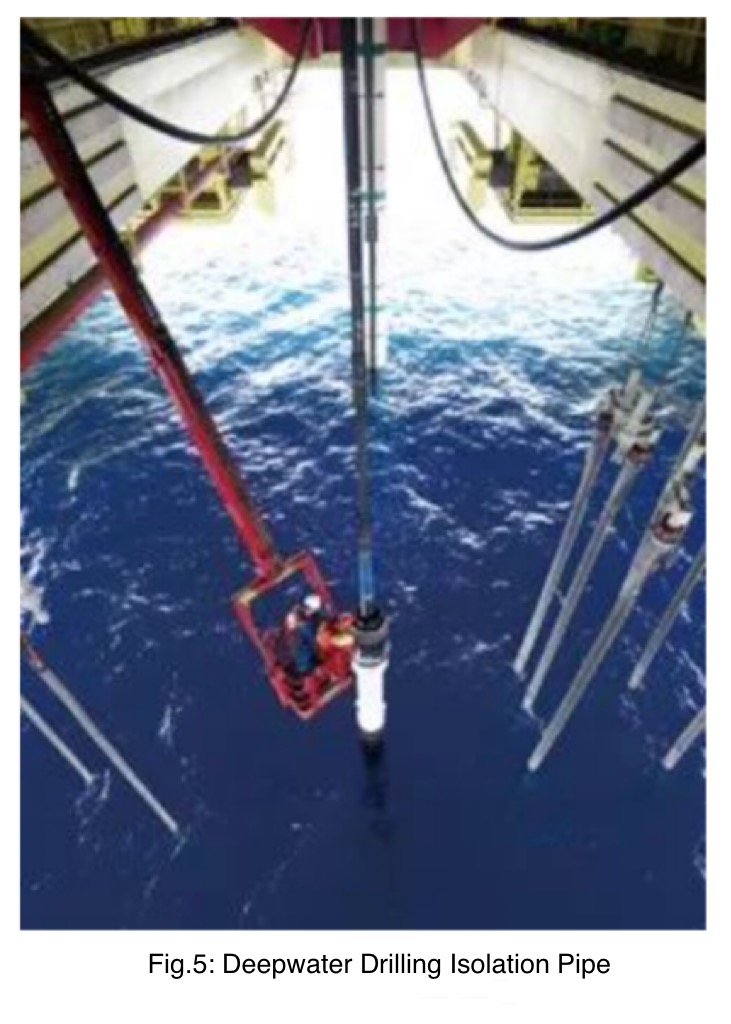

However, China has problems in the field of deepwater oil and gas drilling, such as poor manufacturing quality and reliability of high-end products, lagging research and development of lightweight and high-performance materials, reliance on imports for core equipment and components, and incomplete system of major equipment. In terms of key equipment for deepwater drilling, such as deepwater conduit delivery tools, deepwater drilling risers (Figure 5), and pressure control drilling systems, China still relies on imports and lacks independent intellectual property rights in deepwater drilling software systems, lagging behind international advanced levels. Based on projects such as the "863" Plan, the "973" Plan, the National Science and Technology Major Special Project, and the National Key R&D Plan, four well-known domestic petroleum equipment suppliers, including Baoji Petroleum Machinery Co., Ltd. and Sinopec Jiangzuan Petroleum Machinery Co., Ltd., have produced underwater oil extraction trees; North China Petroleum Rongsheng Machinery Manufacturing Co., Ltd. has developed a deep-water underwater blowout preventer; However, the above-mentioned key equipment lacks a full-scale testing platform and lacks demonstration and application promotion.

3. Key Technologies and Equipment Development Trends and Suggestions for Deepwater Oil and Gas Drilling

The key technologies and equipment for deepwater oil and gas drilling are the core links to ensure the development of deepwater oil and gas drilling.In order to solve the bottleneck problem in China's deepwater oil and gas drilling field and ensure national energy security, CNOOC focuses on technological innovation, continues to adhere to demand orientation, promotes the combination of "industry, academia, research, and application", strengthens scientific research and research in the intersection of digitalization, intelligence, and traditional oil and gas fields, further promotes the replacement and upgrading of technologies such as deepwater intelligent drilling, rotary steering, and intelligent drill strings, as well as intelligent drilling rigs, FPSO platforms The research and application of major high-end equipment such as intelligent platforms provide strong technical and equipment support for the high-quality development of China's deepwater oil and gas drilling industry.

3.1 Development Trends of Key Technologies for Deepwater Oil and Gas Drilling

3.1.1 Deepwater Intelligent Drilling Technology

Deep water intelligent drilling technology is a marine oil and gas drilling and development technology based on modern information technology and artificial intelligence algorithms, with the main purpose of improving drilling efficiency and safety, while reducing costs.This technology can optimize the drilling process and reduce operational errors and accidents through real-time monitoring of wellhead and bottom hole parameters, intelligent decision-making and control of the drilling process, as well as data analysis and prediction.

The Hi-Drill and E-Drilling systems developed by Norway's Konsberg Oil and Gas Company are currently leading intelligent deepwater drilling technologies. Among them, Hi-Drill achieved automation of personnel and technical training through the establishment of a simulation training system, which is used to improve the training efficiency and quality of drilling professionals. The E-Drilling system is an innovative real-time dynamic simulation, 3D visualization, and remote drilling monitoring system. This system monitors and optimizes the drilling process through real-time simulation, and directly displays real-time and simulated data through a three-dimensional virtual wellbore. E-Drilling 2D can monitor drilling data in real-time and display both measured and calculated data curves to compare and display whether there are any abnormalities underground.

At present, CNOOC has preliminarily established an E-Drilling system, which can provide safety guarantees for drilling risk monitoring and underground risk identification. As offshore oil and gas drilling moves towards deep water, intelligent deepwater drilling technology will become one of the main development directions for future deepwater oil and gas drilling.

3.1.2 Deepwater Oil and Gas Drilling Big Database Technology

With the continuous expansion of the scope and difficulty of offshore oil and gas drilling, traditional data management methods are no longer able to meet the needs of efficient management and intelligent analysis of a large amount of data in offshore oil and gas drilling development. Therefore, the deep water oil and gas drilling big database technology has emerged and has become one of the essential technical means in modern deep water oil and gas drilling and development.

Deepwater oil and gas drilling big database technology is a technology based on the accumulation of a large amount of data in the field of marine oil and gas, which achieves large-scale, efficient, and comprehensive data management, analysis, and utilization through computer technology. It takes data as its core and provides more comprehensive, in-depth, and accurate data support for deep water oil and gas drilling and development through data collection, storage, management, processing, analysis, and application. As a typical representative of large database technology, the SiteCom® system of Norway's Konsberg Oil and Gas Company covers geological, oil reservoir, drilling, testing, completion, workover, and production operation data, achieving the integration of multi-disciplinary data in offshore oil fields. In the future, with the continuous development of technology, the large database technology for offshore oil and gas drilling and development will play an increasingly important role, becoming an important support for achieving sustainable development of offshore oil and gas resources.

3.1.3 Deepwater Oil and Gas Rotary Steering Drilling and Logging while Drilling Technology

Rotary guided drilling and logging while drilling technology can accurately control the drilling direction of the drill bit in rock formations thousands of meters deep underground, achieving "staring" at oil and gas, "aiming" at boundary drilling, and even stably traversing several kilometers in thin oil layers only 1 meter thick. At the same time, this technology can analyze formation data in real-time, significantly reducing the cost of oil and gas field drilling and development. It is a key core technology for the efficient development of conventional oil and gas, shale gas, coalbed methane, combustible ice and other resources globally, representing the highest level of development in drilling and logging technology in the world today.

As of 2023, the first rotary steering drilling and logging while drilling system (referred to as "Xuanji" system) independently developed by CNOOC has successfully achieved 1000 well operations and a total drilling footage of 1 million meters, with key operational indicators reaching world-class levels, marking a milestone leap in China's high-end oil and gas drilling technology.

3.1.4 Intelligent Drilling String Technology for Deepwater Oil and Gas Drilling

The drill string is an important tool for achieving high-quality and fast drilling, and it is a key hub for connecting with the underground. The intelligent drill string adopts high-precision sensors and modern data acquisition technology, which can detect and correct the inclination and deviation of the drill string in real-time, reduce the probability of downhole accidents, and ensure the safety of drilling operations. In addition, the intelligent drill string can automatically adjust the speed and torque, making the drill bit more adaptable and effective in different formation conditions. Finally, the intelligent drill string can provide high-precision drilling data, including the position of the contact point between the drill bit and the formation, wellbore stability, etc., providing important reference data for subsequent reservoir evaluation and development. This technology effectively improves the safety and efficiency of deepwater drilling, and provides strong support for optimizing drilling processes. In current and future offshore oil and gas drilling projects, intelligent drilling string technology will become the main development trend of deepwater drilling technology.

3.1.5 Suggestions for the Development of Key Technologies in Deepwater Oil and Gas Drilling

Deepwater oil and gas drilling, as one of the hotspots in the current international oil and gas exploration and development field, is one of the important means to achieve national energy security and sustainable economic development. In the face of increasingly tense energy supply and demand relationships and rapid consumption of oil and gas resources, it is urgent to focus on the development of key technologies in the field of deepwater oil and gas drilling from a strategic perspective. Due to the fact that deep-water oil and gas drilling is usually located in deep sea areas with long offshore distances, issues such as safety, drilling efficiency, and drilling costs are more prominent in deep-water oil and gas drilling. In the future, deep water oil and gas drilling technology should have a strategic layout of key core technologies, strengthen the research and development of deep water oil and gas drilling technology, promote the application of digital and intelligent technology, strengthen technological innovation and international cooperation, and pay attention to environmental protection and safety management of deep water oil and gas drilling, achieve orderly development and utilization of deep water oil and gas resources, ensure China's energy security, and create the source of original technology, Subsequently, it will promote the sustainable development of China's deep-sea oil and gas and other marine resources, as well as the advancement of energy technology towards a higher level of self-reliance and self-improvement.