Current Status and Prospects of Oil and Gas Pipeline Technology Development

Abstract

On the basis of comparing the current situation of oil and gas pipeline construction at home and abroad, the article summarizes the development status and main achievements of key technologies in China's oil and gas pipelines. Combined with the "carbon peak, carbon neutrality" strategy and energy supply requirements, it looks forward to the future development trend of China's oil and gas pipeline technology, in order to provide reference for the subsequent development of oil and gas pipeline related technologies.

1. Current Situation of Oil and Gas Pipeline Construction at Home and Abroad

1.1 Current Situation of World Oil and Gas Pipeline Construction

As of 2020, the total mileage of in-service oil and gas pipelines worldwide is approximately 2.019 × 106 km, including natural gas pipelines approximately 1.350× 106 km, crude oil pipeline approximately 4.01 × 105 km, finished oil pipelines approximately 2.68 × 105 km. North America, Europe, Russia, Central Asia, and the Asia Pacific region are the main distribution areas of global oil and gas pipelines, with the United States, Russia, and China ranking among the top three in terms of total pipeline mileage.

The North American region has established the world's most integrated oil and gas pipeline network system, with a total length of oil and gas pipelines approximately 8.4×105 km in service; Europe has established a pipeline network system mainly consisting of imported pipelines and regional interconnecting pipelines, with a total mileage of oil and gas pipelines approximately 3.15×105 km in service; The total pipeline mileage in Russia and Central Asia is approximately 2.961×105 km. From the perspective of the development trend of oil and gas pipeline construction, the Asia Pacific region is currently in a stage of rapid economic development, and the construction of oil and gas pipeline infrastructure will accelerate.

1.2 Current Situation of Oil and Gas Pipeline Construction in China

China has become the world's third largest pipeline country, creating and developing an oil and gas pipeline technology system that adapts to China's oil and gas characteristics, safeguarding energy strategic security and national economic development. As of the end of 2021, the total mileage of oil and gas long-distance pipelines built in China has reached 1.48×105 km, with a natural gas pipeline mileage of approximately 8.76×104 km, crude oil pipeline mileage approximately 3.13×104 km, with a product oil pipeline mileage of approximately 2.91×104 km.It is expected that by 2025, the scale of the national oil and gas pipeline network will reach 2.4 × 105 km. In terms of supporting reserve warehouses and large-scale reserve warehouse construction, a total of 9 national oil reserve bases have been built, including Zhoushan, Zhoushan expansion, Zhenhai, Dalian, Huangdao, Dushanzi, Lanzhou, Tianjin, and Huangdao national oil reserve caverns; 22 liquefied natural gas receiving stations have been built, with a total receiving capacity of 1.0225×108 t/a; 30 gas storage facilities with a capacity of 5.4009×1010 m3, with a peak shaving capacity of approximately 1.4969×1010 m3.

2. Current Development Status, Needs and Challenges of Key Technologies for Oil and Gas Pipelines in China

2.1 Breakthrough Progress in Pipeline Construction, Construction, and Equipment Research and Development

(1). Breakthroughs have been made in the localization of large-diameter and high-pressure pipeline manufacturing technology and equipment. The completed China Russia East Line natural gas pipeline is the first internationally adopted pipeline with a large diameter of 1422mm, X80 high steel grade, and 12 MPa high pressure, achieving the localization of a series of equipment.

①.Localization of pipe manufacturing technology.

Domestic X80 steel pipes have been widely used in practical engineering construction, with construction mileage exceeding the total mileage of foreign X80 pipelines.

②.Localization of core equipment.

Key equipment such as compressor units, oil pump units, and large diameter fully welded ball valves have been independently manufactured, and the localization rate of the entire pipeline core equipment has reached 95%.

(2) . The pipeline construction and supporting technology under complex geological conditions are constantly developing and improving.

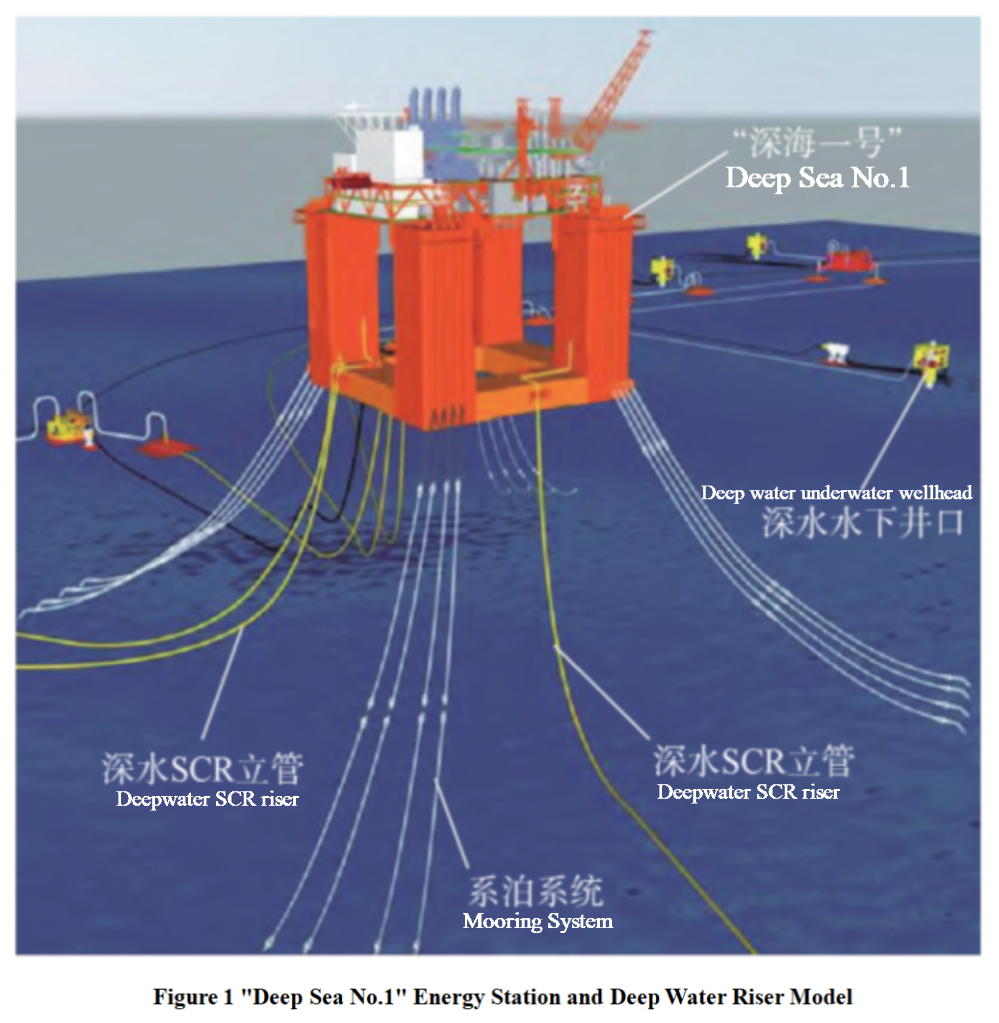

①.Submarine pipelines are laid towards the deep sea.

We have established a deep water submarine pipeline engineering technology and equipment system, possessing the technical ability to independently construct a 1500 meter ultra deep water oil and gas pipeline. We have completed the "Deep Sea No.1" project and successfully put it into operation. As shown in Figure 1; A series of special engineering construction ships and equipment such as "Offshore Oil 201" and "Offshore Oil 286" have been developed to achieve a breakthrough in the depth of submarine pipeline laying from 300 m to 1500 m.

②.Breakthroughs have been made in pipeline laying in permafrost regions.

The China Russia crude oil pipeline, the Desert Line, is the first pipeline in China to pass through permafrost regions. Faced with the challenges of permafrost degradation, low temperature, and fragile ecology in pipeline construction, it has innovatively proposed principles and systematic solutions for permafrost regulation.

2.2 Pipeline safety evaluation technology has entered a new stage of development

(1).Pipeline integrity management technology is becoming more perfect.

We have established a risk assessment method suitable for China's national conditions, developed a risk assessment technology for equipment and facility operation and maintenance, and comprehensively improved the management level of equipment operation and maintenance. New achievements have been continuously made in key technologies and industrial applications of integrity management. In 2002, the internal inspection of large diameter natural gas pipelines on the Shaanxi Beijing line was completed for the first time in China. In 2012, we overcame the technology of spiral weld inspection and evaluation.Since 2015, national and industry standards such as the Implementation Guidelines for Pipeline System Integrity Management (SY/T 6975-2014) and the Specification for Integrity Management of Oil and Gas Pipeline Systems (GB 32167-2015) have been successively released. The implementation of integrity management has significantly enhanced China's pipeline safety assurance capabilities.

(2).Pipeline safety evaluation technology has entered a new stage.

The application of high-strength pipeline steel poses new challenges to pipeline safety evaluation. In terms of pipeline crack prevention, the conditions for strain aging of X80 high-strength pipeline steel under service conditions have been clarified. The toughness and crack arrest ability of high-strength pipeline steel (especially in the weld zone) materials will decrease; We studied crack arrest control using crack tip opening angle as a toughness parameter for crack arrest. With the extension of service time of oil and gas pipelines, the problem of corrosion failure faced by pipelines is becoming increasingly severe.

At present, the corrosion mechanism of weak acids has been clarified, and corresponding corrosion prediction models have also become mature. Combining flow models and corrosion mechanisms to establish a corrosion rate prediction method is one of the goals for accurately evaluating oil and gas pipeline corrosion in the future. In order to better prevent and control pipeline explosion accidents, a research on pipeline oil and gas explosion experimental system has been carried out, providing reference for the safety and protection design of oil and gas pipelines.

(3).Phased achievements in reliability research of natural gas pipelines.

As China's natural gas pipeline construction enters a stage of rapid development, reliability based design and evaluation methods are the development direction for the reliable operation of large natural gas pipelines and the guarantee of gas supply. In terms of pipeline design, reliability based design and evaluation methods are used to design for actual failure forms, and a pipeline reliability calculation framework has been established. In terms of ensuring gas supply, a method for calculating the reliability of gas supply in gas transmission networks based on uncertain gas consumption has been developed, taking into account the randomness of user gas consumption, which is more in line with the actual situation.

2.3 Continuous Development of Simulation Technology for Large and Complex Oil and Gas Pipeline Networks

With the accelerated formation of the "National One Network", it is necessary to carry out research on the simulation and operation optimization technology of large-scale complex oil and gas pipeline systems with multiple sources and sinks.

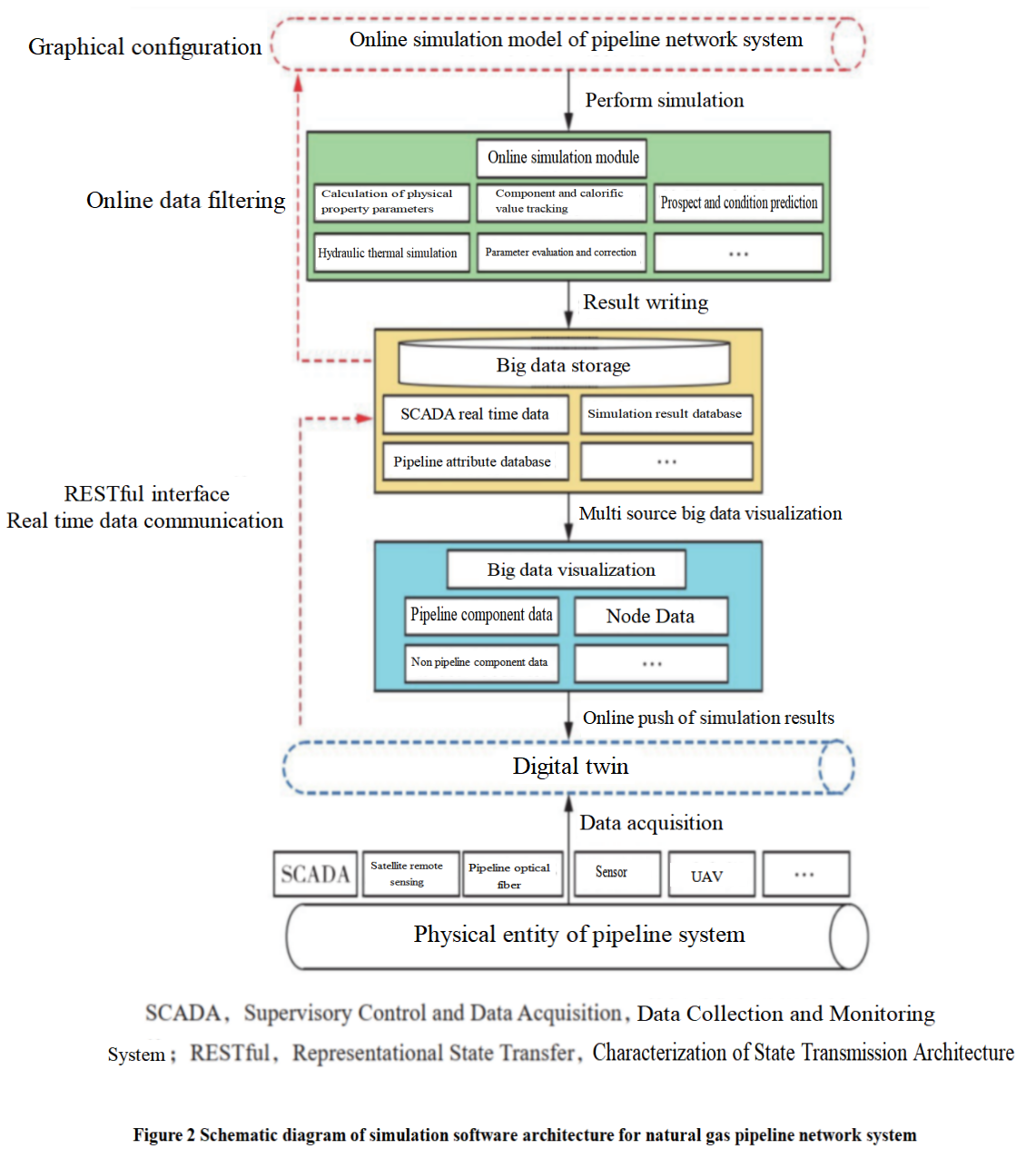

After decades of development, the simulation technology of oil and gas pipelines has made breakthroughs, and its adaptability to the scale of pipeline networks is comparable to that of foreign commercial software; Domestic natural gas pipeline network simulation software has been successfully applied in natural gas pipelines such as the Sichuan East Gas Pipeline and the Western South China Sea subsea natural gas pipeline. China's oil and gas gathering and transportation pipeline network simulation software has achieved localization. The planning, operation, and scheduling technologies of the finished oil pipeline network are becoming increasingly mature, and a universal simulation software for scheduling the finished oil pipeline has been developed. The pipeline simulation mode has been developed from offline simulation to online simulation, and the applicable scale has shifted from small pipeline networks to large complex pipeline networks (see Figure 2).

2.4 Continuous deepening of flow guarantee technology for oil and gas pipelines

Based on the characteristics of high wax content and high pour point in Chinese crude oil, and through independent innovation, the rheological research and modified transportation technology of easy to pour and high viscosity crude oil have taken an international leading position, establishing a safe and economic transportation theory and method for easy to pour and high viscosity crude oil.

In the field of crude oil modification technology and its engineering applications, pour point depressant modification and electromagnetic modification have become the new generation of crude oil modification technologies, and the study of crude oil flow guarantee system has been continuously promoted. We have successively developed crude oil pipeline modification transportation technology, drag reduction and increase transportation technology, etc. At the same time, significant progress has been made in the thermal impact between alternating cold and hot oil transportation, intermittent transportation, and pipeline laying in the same trench, reflecting the high-quality development of China's crude oil pipeline flow guarantee technology.

Continuous progress has been made in the flow guarantee technology of offshore oil and gas pipelines. Due to the complex media and harsh underwater environment transported by submarine pipelines, offshore oil and gas pipelines face severe flow safety challenges. We have conducted in-depth research and application around flow safety design technology, flow safety monitoring, and flow management technology. For flow safety monitoring, a submarine pipeline leakage detection system has been formed that integrates distributed optical fiber, sequential probability, and infrasound wave leakage. Based on the pressure pulse wave detection method, hydrate blockage monitoring technology has been developed.

In response to the multiphase mixed transportation of high viscosity crude oil in subsea pipelines, theories and technologies for predicting and preventing solid phase deposition in subsea pipelines have been developed, gradually forming a wax and hydrate solid phase prevention and control technology system. The process design method for mixed transportation pipelines with the addition of viscosity reducing and drag reducing agents has been applied.

2.5 Continuously making new progress in oil and gas gathering and processing technology

The research on oil and gas gathering and processing technology has made continuous progress. In terms of oilfield gathering and transportation, it includes non heating oil gathering technology, formation heat energy utilization technology, and software oil measurement technology. In terms of gas field gathering and transportation, it includes downhole throttling technology, simplified metering technology, efficient gathering and transportation technology for high sour gas fields, and purification technology for high sulfur and high carbon natural gas. High strength and high sulfur wet gas gathering and transportation pipes and anti-corrosion processes have been developed.

A technology system of gravity sedimentation, cyclone separation, and electric field demulsification based pre separation of produced liquid has been developed for the development period of high water bearing oil fields. It has formed technological advantages in compact gas-liquid separation, enhanced oil-water separation, and efficient sewage treatment technologies. In the field of natural gas separation, supersonic cyclone separation technology has been developed. Under the trend of green and low-carbon development in oil and gas field surface engineering, a technology system for reducing volatile organic compounds in oil and gas storage tanks has been formed. From the overall evaluation level, an energy efficiency index system for oil and gas field gathering and transportation systems has been established to help improve the energy efficiency level of the gathering and transportation systems.

2.6 Accelerated development of oil and gas storage and liquefied natural gas technology

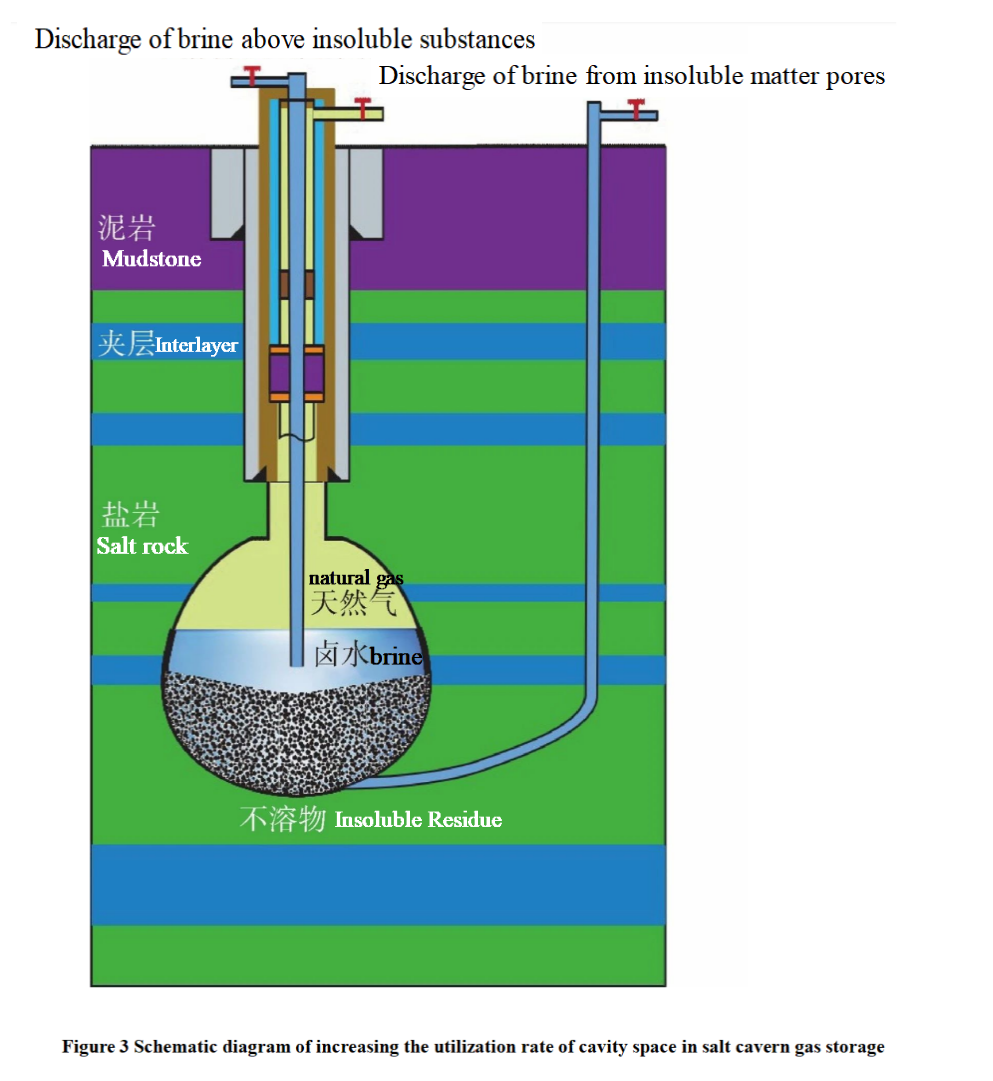

Underground water sealed storage is one of the important ways to store energy such as oil. A dynamic optimization method for water curtain water level based on monitoring data has been established, and a method for evaluating the water sealing risk of cave expansion and seawater intrusion has been proposed. Stability monitoring technology for underground cave storage has been developed. Underground gas storage is the main method for peak shaving and strategic storage of natural gas.

After more than 20 years of construction practice, we have overcome external difficulties such as poor geological conditions and slow digestion of brine during the construction of the reservoir. China has developed a series of new technologies and equipment with independent intellectual property rights. We have developed a simulation technology for complex salt layer water solution cavities, developed repair methods for irregular cavities in layered salt rocks, and established a series of key theories and new technologies for constructing underground reserves in complex salt rock formations, as shown in Figure 3.

Liquefied natural gas storage is an important infrastructure for imported liquefied natural gas to be integrated into the natural gas pipeline network. The localization of liquefied natural gas equipment is being systematically promoted, and the application of low-temperature 9% Ni steel has been successfully achieved; In terms of liquefaction process, technologies such as single cycle mixed refrigerant natural gas liquefaction, double cycle mixed refrigerant natural gas liquefaction, and propane pre cooled mixed refrigerant cycle natural gas liquefaction have been formed, and key processes and equipment for floating natural gas liquefaction devices suitable for marine and marginal gas fields have been overcome.

In order to meet the requirements of energy conservation, consumption reduction, and green environmental protection, new cold energy utilization processes have been developed, such as the low-temperature evaporative gas recondensation process based on pressure swing adsorption nitrogen production systems.

3. Development Trends of Oil and Gas Pipeline Technology in China

The "Medium and Long Term Oil and Gas Pipeline Network Plan" clearly states that China is promoting a revolution in energy production and consumption, and the position of oil and gas in energy is gradually improving. In the next 10-15 years, it will still be the peak period of oil and gas pipeline construction. It is expected that by 2030, the total mileage of China's oil and gas pipelines will reach 2.5×105~3×105 km, with a modern oil and gas pipeline network system basically established.

3.1 Oil and gas pipelines targeting the goal of "carbon peaking and carbon neutrality"

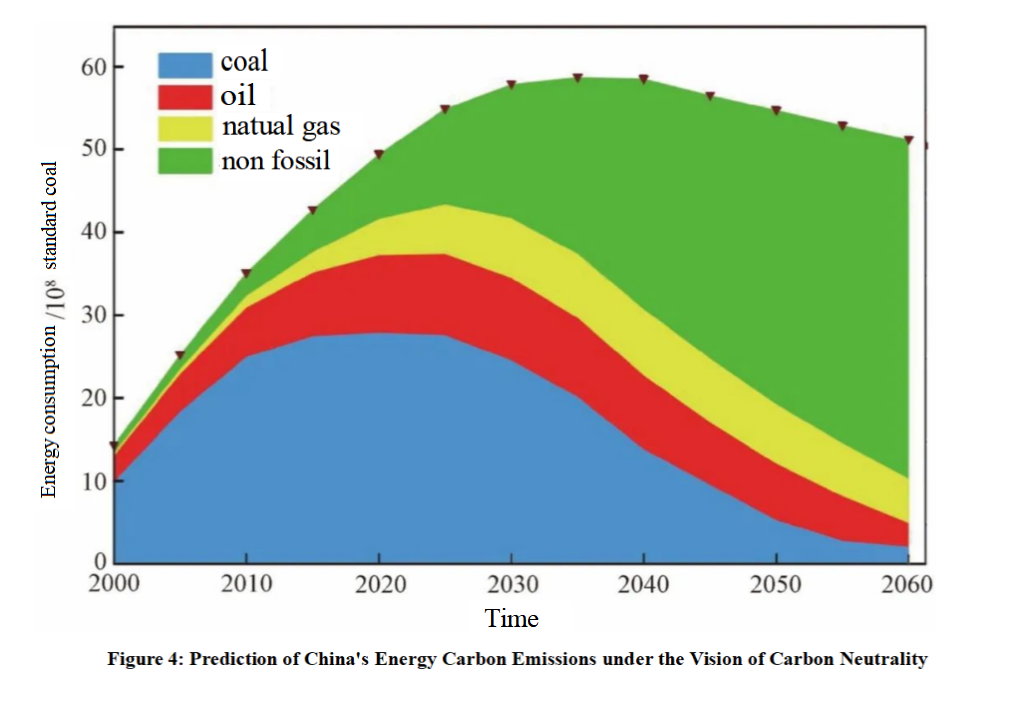

Under the transformation of energy structure, oil and gas storage and transportation undertake new tasks. Under the goal of achieving carbon peak and carbon neutrality, the energy consumption structure will accelerate the transformation from traditional fossil fuels to clean and low-carbon new energy. As shown in Figure 4, oil and gas pipelines will face new challenges and tasks.

On the one hand, we will further promote the simulation and optimization of large-scale natural gas pipeline networks, the transportation of easily condensable and viscous crude oil pipelines, the energy efficiency and net zero emissions of oil and gas pipelines, and the construction of smart energy systems.

On the other hand, we will coordinate and promote the research and development, demonstration, and industrial application of large-scale carbon capture, utilization, and storage (CCUS) technology, as well as the full chain development of hydrogen energy "production-storage-transmission-use".

For the new tasks of CCUS and hydrogen energy storage and pipeline transportation, it is necessary to focus on the research and development of new theories and technologies such as CO2 pipeline transportation and storage, natural gas pipeline hydrogen blending and pure hydrogen transportation.

3.2 Intelligent and multi energy complementary oil and gas pipeline network

Under the transformation of energy structure, the energy internet is gradually forming, and renewable energy will gradually become the main energy source.

The future task is to continuously promote the development of smart oil and gas pipeline network technology, form a sensing system for comprehensive perception data analysis of pipeline networks, promote the digitization of all elements, full state visualization, and intelligence of oil and gas pipeline networks, and break through key technologies such as comprehensive perception, data mining and utilization, and intelligent comprehensive decision-making of pipeline networks.

Taking the oil and gas pipeline network system as the starting point, combined with internet technology, we continuously explore the advantages of natural gas pipeline networks in peak shaving and energy storage in the energy internet, actively explore the participation mode and development direction of oil and gas pipeline networks in the energy internet, in order to achieve complementarity between multiple energy sources.

3.3 New medium storage and transportation and unconventional pipeline technology

Based on the characteristics of oil and gas pipelines, in the transformation of energy consumption structure, new medium storage and transportation and unconventional pipeline technology will be one of the key technologies for future oil and gas pipelines.

CO2 pipeline transportation technology assists the comprehensive promotion of CCUS, based on energy structure adjustment and energy utilization efficiency improvement. It is expected that China's CO2 emissions will peak before 2030, and the CO2 emissions by 2060 will be about 1.5 × 109 tons, estimated to require CCUS utilization scale of approximately 1.0 × 109 tons, pipeline transportation will become the key to CCUS technology, and we should focus on tackling CO2 pipeline transportation technology and safety critical technologies.

Actively carry out research on the safety technology of pure hydrogen and hydrogen doped natural gas pipelines, utilize existing natural gas pipelines to transport hydrogen in the form of hydrogen doped natural gas, accelerate the development of hydrogen energy pipelines, and focus on promoting the research and development of composite hydrogen storage technology. Exploring the use of high-pressure natural gas pipelines to transport new energy through capsule transportation technology, loading new energy media into the capsule and utilizing the driving force of the fluid in the pipeline to achieve the transportation of the capsule.

3.4 Development Suggestions

Actively promote the construction of natural gas pipelines and leverage the key role of natural gas in the transformation of energy consumption structure.

Develop simulation and control technologies for large-scale oil and gas pipelines with multiple sources and sinks, accelerate the integration of storage and oil and gas pipelines, and accelerate the process of intelligent oil and gas pipelines.

Promote safety evaluation technology for high-strength pipeline steel, and improve relevant standards and regulations for integrity management of high-grade steel pipelines.

Promote the research and development of flow characterization and modification technologies for the mixed transportation of easily condensable and high viscous crude oil for deepwater oil and gas transportation, develop a solid phase prevention and control technology system for wax and hydrate in submarine pipelines, and improve the flow guarantee technology for submarine pipelines.

Implement independent research and development of key equipment and processes for submarine pipelines and underwater production facilities.

Optimize the process of surface gathering and transportation system, carry out the transformation of old oil and gas fields, and construct a new energy comprehensive development system for new oil and gas fields from the perspective of comprehensive energy efficiency, to achieve green and low-carbon development.

For the transportation of new media, we will tackle pipeline processes such as CO2 and H2, as well as safety protection technologies, and accelerate the establishment and improvement of technical standards, policies, and regulations.

4. Conclusion

After nearly 70 years of development, China's oil and gas pipeline industry has gradually formed a complete technical system that adapts to China's national conditions, supporting the high-quality development of China's oil and gas industry and achieving brilliant achievements. Some fields of technology have reached international leading levels, but there are still gaps compared to foreign countries in some aspects. Under the goal of achieving carbon peak and carbon neutrality, combined with intelligent technology, new medium pipelines, and unconventional pipeline technologies, oil and gas pipeline technology will inevitably usher in new reforms and innovations.