Current Status and Development Suggestions of China Petroleum Continental Shale Oil Drilling Technology(Part 4)

2.2.4 Drilling fluid and cementing matching technology

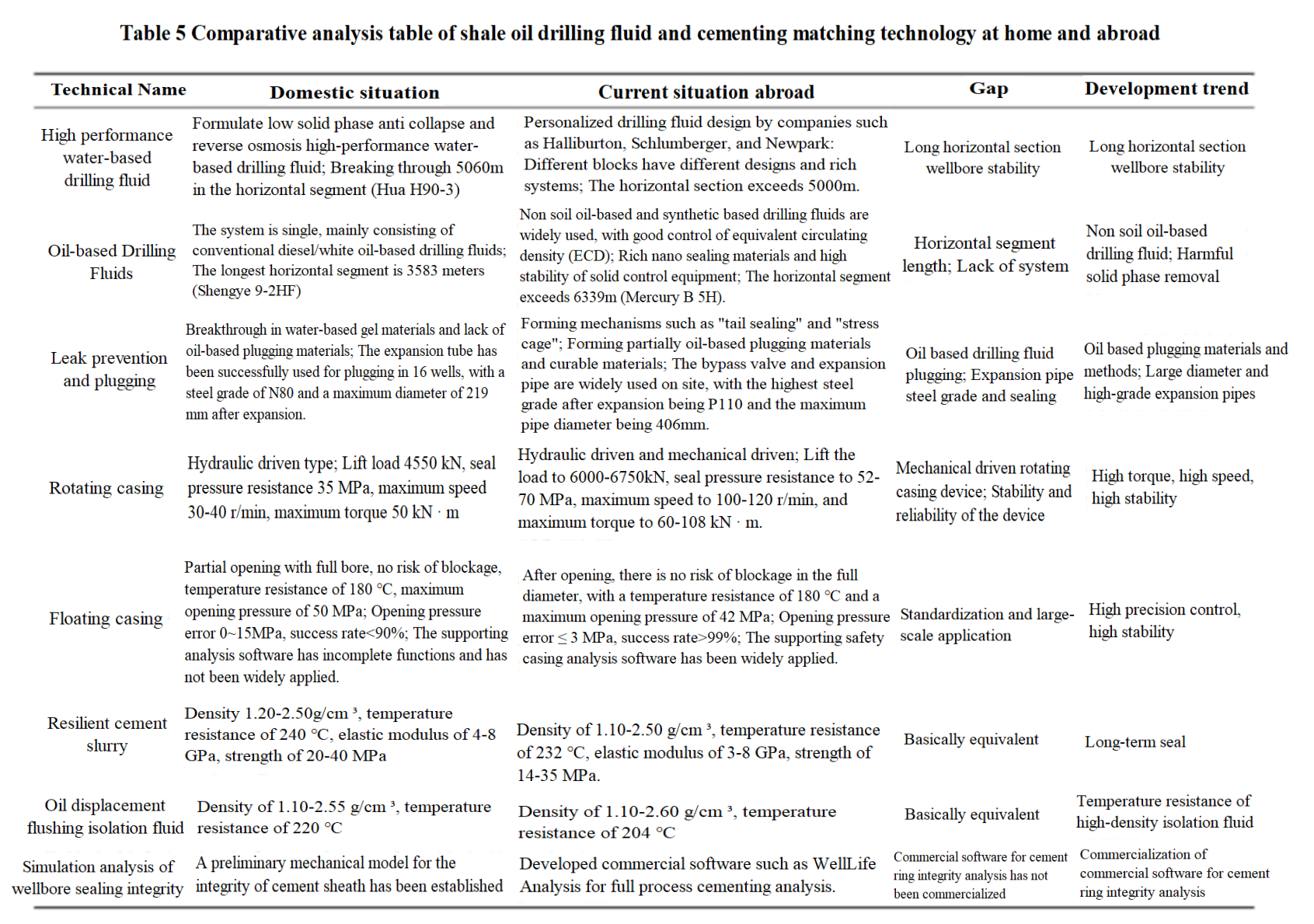

Jimsar and Gulong shale oil drilling in China are mainly oil-based drilling fluid, while Longdong shale oil is mainly water-based drilling fluid, forming oil-based drilling fluid leak prevention and plugging technologies such as gel microspheres, expansion tubes, cement, etc., and oil-bearing cuttings are mainly treated by thermal desorption.Compared with key drilling fluid technologies abroad, the domestic drilling fluid system is single, with high friction in long horizontal sections and a lack of specialized plugging materials for oil-based drilling fluids. The benchmarking situation is shown in Table 5.

In terms of casing technology for shale oil in long horizontal sections, China has developed a series of rotating casing devices and full bore floating couplings with independent intellectual property rights, which have achieved safe casing placement for ultra long horizontal sections (>3000 m) of horizontal wells, effectively reducing the incidence of casing deformation and ensuring wellbore integrity.However, the technical indicators such as lifting load, sealing pressure resistance, speed and torque of the rotating casing device are only 50%~70% of the advanced indicators abroad, and there is still a certain gap in the stability and reliability of the device; The independent research and development of a mechanically driven rotating casing device has not yet been achieved; There is a gap in the standardization and large-scale application of floating casing tools, and a unified standard has not been formed. The overall success rate of on-site application is low.

In terms of cementing technology, a preliminary mechanical model of cement sheath integrity has been established, and "high-strength, low modulus" tough cement and oil displacement flushing isolation fluid have been developed. A complete set of cementing technology for long horizontal sections has been formed, with tough cement and prestressed cementing process as the core. The comprehensive performance of cement slurry/isolation fluid is basically equivalent to that of foreign countries, but the software for analyzing the integrity of the cement sheath has not been commercialized.

3. Suggestions for the development of shale oil drilling technology

The exploration and exploitation of shale oil in China started relatively late and is still in the stage of exploration, research and experimentation. Although the strengthening of technological research and exploration has initially formed a technology system for drilling and completing horizontal wells in terrestrial shale oil, there are still technical problems and challenges such as the limited applicability of the "one trip drilling" technology and insufficient research and development of fine guidance tools. The optimal and fast drilling technology for ultra long horizontal wells on large platforms needs to be breakthrough.In the face of the complex and ever-changing geological conditions of terrestrial shale oil in China and the urgent demand for innovative development of drilling technology in the shale oil revolution, combined with advanced foreign experience, drilling and completion technology is anchored with the goals of accelerating, reducing costs, increasing efficiency, and improving production. With the guidance of supporting the current and leading the future, focusing on improving unconventional oil and gas drilling speed, horizontal section extension ability, and high-quality reservoir drilling encounter rate, key technologies for shale oil horizontal well optimization and fast drilling are carried out to support efficient exploration and development of terrestrial shale oil.

3.1 Continuously promote the industrial operation of large platforms, optimize wellbore structure, and create conditions for drilling speed increase, cost reduction, and efficiency improvement

By strengthening the integration of geological engineering research, enhancing preliminary evaluation, optimizing the horizontal section orientation, length, and spacing of horizontal wells in a reasonable manner, implementing multi-level three-dimensional development, and forming the well network in one go, the total number of drilling platforms can be further increased, effectively expanding the platform scale, improving operational efficiency, and effectively reducing well construction costs.

Drawing on the concepts of "slimming down and speeding up" and "slimming down and reducing costs" of foreign and Sinopec Fuling shale gas well structures, combined with the characteristics of the block, we will continue to optimize the wellbore structure. Jimsar in Xinjiang and Gulong in Daqing continue to promote the double opening wellbore structure, releasing space for speed increase; By simplifying the wellbore structure and using small hole drilling technology, the cost of drilling and completion materials and the energy consumption of flowback material treatment can be reduced, promoting the cost reduction, efficiency improvement, and green development of unconventional oil and gas.

3.2 Integrated supporting acceleration technology to increase the proportion of "one trip drilling" and shorten the drilling cycle

The breakthrough in the key technology of "one trip drilling" in North America has promoted the efficient utilization of shale oil resources, forming a core capability to significantly improve single well production, recovery rate, and economic benefits, and continuously innovating acceleration technologies.The most popular phrase in the North American oil industry in 2019 is' One day one mile '. In January 2024, the daily drilling footage from the inclined section to the horizontal section of the LMX formation in the Ning209H73-6 well of Southwest Oil and Gas Field exceeded 1 mile, marking the first time that the daily drilling footage of shale gas horizontal wells in China has jumped to a new level of "daily drilling miles".There is still a significant gap between the key technologies for accelerating shale oil production in China and those abroad, and it is necessary to focus on the localization of "one trip drilling" supporting technologies in terms of matching "equal life" tools and strengthening drilling parameters.

The integration and application of mature technologies such as high-efficiency PDC drill bits, high torque long-life screw drilling tools, low-pressure high-energy hydraulic oscillators, and high-performance drilling fluids for ultra long horizontal wells are preferred; Upgrade the supporting equipment of the drilling rig to meet the requirements of enhanced drilling parameters and improve the wellbore cleaning ability; Continuously improving the ability to prevent and quickly handle complex underground situations; Based on the characteristics of the block, establish a drilling acceleration technology template, strengthen iterative upgrading and on-site execution.

Actively explore the application scenarios of artificial intelligence and establish a new model of deep integration between artificial intelligence, cloud computing, and traditional drilling and completion engineering technology. Using big data and intelligent optimization algorithms to optimize multi-objective drilling parameters, achieving optimal matching between formation, drill bit, and parameters, intelligently optimizing mechanical drilling speed, reducing non production time, increasing drill bit footage, and improving drilling efficiency.

3.3 Strengthen the integrated research of geological engineering, accelerate the research and development of new generation guiding tools, and continuously improve the drilling encounter rate of high-quality reservoirs

In response to the strong heterogeneity of unconventional reservoirs in China, we will implement the concept of integrated geological engineering development and rapidly promote the practice of integrated geological engineering. Establish a detailed three-dimensional geological and geostress model, carry out three-dimensional fine carving of reservoirs, and combine sweet spot optimization and precise fracture parameters to design the development block as a whole. Guide the design of horizontal well trajectory and conduct risk assessment and early warning of factors that may affect drilling encounter rate.

Accelerate the research and development of domestically produced high slope and high temperature resistant 175℃ rotary guiding tools, reserve new guiding tools such as hydraulic clutches and intelligent guiding drill bits, accelerate import substitution, and reduce engineering costs.

By integrating geological engineering data such as 3D seismic, geological models, logging curves while drilling, and inversion data from edge exploration tools, and integrating wellbore trajectory parameters, formation parameters, drilling parameters, and tool parameters, real-time monitoring and evaluation of wellbore trajectories are achieved. Reservoir target positioning is updated to achieve real-time optimization of wellbore trajectories, improve reservoir drilling encounter rates and wellbore quality, and achieve high ultimate recoverable volume (EUR), high recovery rate, and high return on investment for shale oil. This lays a solid foundation for the development strategy of "penetrating" unconventional onshore reservoirs.

4. Conclusions

Since the 14th Five Year Plan, China Petroleum's onshore shale oil drilling technology has developed rapidly, forming supporting technologies such as segmented drilling, high-performance drilling fluids for horizontal wells, integrated geological guidance, and large-scale platform factory operations, promoting the large-scale application of shale oil horizontal wells. The main engineering and technical indicators have been improving year by year, with key indicators in some areas comparable to those in North America, providing strong support for the large-scale construction and rapid production of shale oil blocks in Longdong, Changqing, Jimusaer, Xinjiang, and Gulong, Daqing.

China National Petroleum Corporation will focus on developing shale oil in Longdong, Jimsar, and Gulong regions, with an expected annual oil production of 598 × 104 tons by 2025. The resource endowment and geological conditions of terrestrial shale oil in China determine the high difficulty and high cost of shale oil exploration and development, which in turn puts forward higher technical requirements. The optimal and fast drilling technology for horizontal wells on shale oil platforms needs to be breakthrough, and there is an urgent need to improve reservoir drilling encounter rates and reduce drilling cycles.It is recommended to continue promoting the industrial operation of large platforms, optimizing the wellbore structure, and creating conditions for speeding up drilling, reducing costs, and increasing efficiency; Integrate supporting acceleration technology, increase the proportion of "one trip drilling", and shorten the drilling cycle; Strengthen the integrated research of geological engineering, accelerate the research and development of new generation guiding tools, and continuously improve the drilling encounter rate of high-quality reservoirs. Develop a unique onshore shale oil drilling engineering technology system with Chinese characteristics, leading the achievement of shale oil revolution engineering goals.