Application of Drag Reducer in Crude Oil Pipeline Transportation Process

Abstract

In the transportation of crude oil pipelines, the addition of drag reducers can effectively reduce the flow friction of crude oil and increase the transportation volume. This article combines the application example of adding drag reducing agents to the Ma Hui line to illustrate the drag reducing and transportation increasing effects of pipeline drag reducing agents in crude oil transportation.

Preface

The flow of fluid in the pipeline generates frictional resistance with the pipe wall, resulting in energy consumption of the entire flow system and reducing the pipeline transport capacity. The method of reducing energy consumption by adding high molecular weight polymers to the fluid being transported and reducing flow resistance in turbulent flow is called high polymer drag reduction method.Polymer compounds used to reduce fluid flow resistance become drag reducers, abbreviated as DRA. Drag reducing agents are an important component of oil pipeline transportation systems, playing a crucial role in improving pipeline transportation capacity and reducing energy consumption.

Crude oil itself is a fluid with high viscosity. When it enters pipeline transportation, its flow state in the pipeline is affected by frictional resistance, resulting in increased energy consumption and decreased pipeline transportation efficiency.In this case, using a small amount of chemical additives to effectively reduce the friction of the pipeline system is of great importance and significance for accelerating the development and utilization of crude oil, ensuring safe transportation, saving investment, reducing energy consumption, and increasing transportation volume.The injection of drag reducing agents can effectively reduce the frictional resistance of fluids in pipelines without changing the operation mode of the pipeline, which plays a very important role in increasing the transmission, energy saving, and improving the economic benefits of oil pipelines.

The drag reduction effect is a special turbulent phenomenon, which is the macroscopic manifestation of the drag reduction effect on the turbulent flow field. It is a pure physical effect. The molecules of drag reducers do not interact with the molecules of oil products, nor do they affect the chemical properties of chemicals, but are closely related to their flow characteristics.In turbulence, the velocity of fluid particles randomly changes, forming large and small eddies. Large scale eddies absorb energy from the fluid, undergo deformation and fragmentation, and transform into small-scale eddies. Small scale vortices, also known as dissipative vortices, are weakened and calmed by viscous forces, and some of the energy they carry is converted into heat and dissipated. In the edge layer near the pipe wall, this transformation is more severe due to the effects of shear stress and viscous force on the pipe wall.

After the drag reducer is added to the pipeline, it is dispersed in a continuous phase in the fluid. With its unique viscoelasticity, the long chains of molecules flow naturally downstream, and its microelements directly affect the movement of fluid microelements.The radial force from the fluid element acts on the drag reducing agent element, causing it to twist and rotate. The gravitational force between the molecules of the drag reducer resists the aforementioned forces and reacts against the fluid elements, changing the direction and magnitude of the fluid elements' action, converting a portion of the radial force into axial force flowing in the same direction, thereby reducing the consumption of useless work and achieving a macroscopic effect of reducing frictional resistance losses.The concentration of drag reducer affects the thickness of the elastic bottom layer formed in the pipeline. The higher the concentration, the thicker the elastic bottom layer, and the better the drag reduction effect. In theory, when the elastic bottom layer reaches the axis of the pipe, the drag reduction reaches its limit, that is, the maximum drag reduction. The drag reduction effect is also related to factors such as oil viscosity, pipeline diameter, water content, and pipe cleaning.

Adding drag reducers during pipeline oil transportation can have two effects: firstly, it can reduce oil flow friction and minimize pressure head loss along the pipeline while maintaining the original oil delivery volume, thereby reducing pump power consumption and saving power energy; Secondly, under the condition of unchanged original pressure, due to the reduction of oil flow friction, the use of drag reducing agents increased pipeline throughput and achieved the goal of increasing transmission.

Examples of using Drag Reducers on Oil Pipelines both Domestically and iInternationally

The Trans Alaska crude oil pipeline in the United States adopts a scheme of adding and removing resistance agents, reducing the original design of 12 pumping stations to 10, and increasing the daily oil transportation volume from 22.26 × 107L to 38.16 × 107L.The pipeline of the North Sea oil field in the UK was originally designed with a diameter of 1066mm. After scheme comparison, a scheme of adding and removing resistance agents during peak hours was adopted, resulting in a diameter of 914.4mm, which greatly reduced investment and met the requirements of transportation volume.

In China, for example, after the successful on-site test of the Tieda Line in 1986, drag reducers were intermittently used for 79 days at three stations in Shenyang, Xiongyue, and Fuxian, with a dosage of 97m. The entire line increased the transportation of crude oil by 17.667×106t, easing the tight situation of Tieda Line's export and achieving significant export exchange rates, creating high economic benefits for the country.The Huatugou Golmud oil pipeline in Qinghai Oilfield was originally designed to have an annual oil transportation capacity of 100×104 tons. However, with the increase in oilfield production, the pipeline's transportation capacity is required to be increased to 150×104 tons per year. If the traditional method of increasing mechanical power is used, all four pump stations need to be rebuilt as heat pump stations, and the original three heat pump stations also need to be renovated and expanded.Not only does time not allow, but the investment is also significant. They conducted a drag reducing agent injection test, and the test results proved that the use of drag reducing agents can easily achieve an annual output of 150 × 104 tons without adding any oil pumps, and the required cost is much lower than the investment in expanding pump stations.

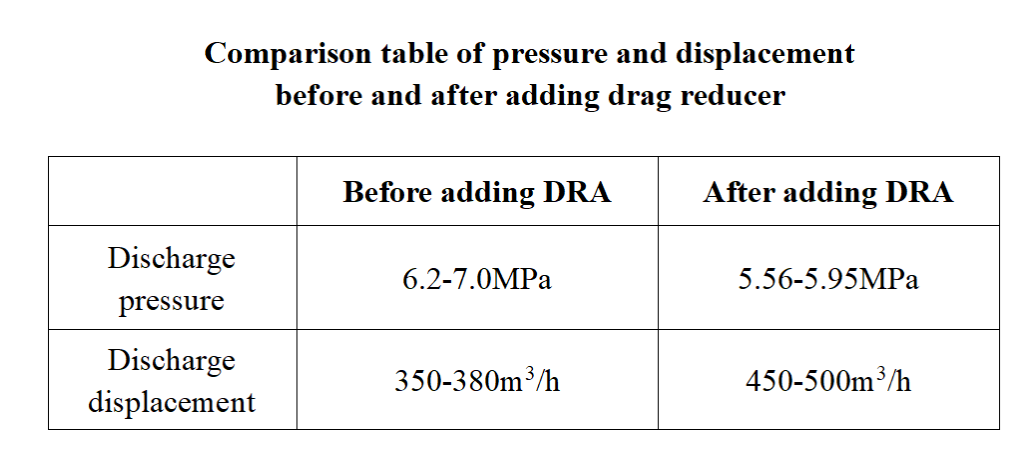

Taking the Ma Hui pipeline site as an example, since the Ma Hui line was put into operation in September 2015, the outflow rate has remained at 350-380m3/h, and the highest outflow pressure is 7.0MPa. The temperature of the oil pump and motor has also increased accordingly. In addition, the indoor temperature is very high in summer, and the operating pressure is very high, which increases the risk of safe operation.After analysis and research, it was finally decided to use a drag reducer. After adding the drag reducer, the output can be increased to 100-120m3/h at the same frequency as the oil pump, and the outlet pressure is significantly reduced (see comparison table).It effectively solves the problems of low export volume, high outlet pressure, and increased parameters of oil pumps, and has achieved objective economic benefits in short-term pipeline production and operation.

Conclusions

By analyzing the application examples of pipeline drag reducers in the crude oil transportation process of the Ma Hui pipeline, and comparing the crude oil transportation volume before and after adding drag reducers, it can be seen that the amount of drag reducer added to the pipeline is small, but the drag reduction effect is significant, which can effectively increase the oil transportation volume of the pipeline and reduce the energy consumption of oil transportation. Based on the analysis of the above examples, it is not difficult to see the positive significance of applying drag reducers on oil pipelines:

1. Significantly reduce investment in pipeline construction. The annual transmission capacity of pipelines is an important reference for designing new pipelines, but due to the complex and variable influencing factors, the annual transmission capacity cannot be accurately estimated.For example, factors such as the accuracy of oilfield reserve estimation results, market changes leading to changes in pipeline oil transportation volume and types of oil products can cause fluctuations in pipeline annual transportation volume over a large range.In response to this situation, it is possible to design according to relatively economical conditions and then use drag reducers to solve situations that exceed the design scope in practical applications. In this way, the pipeline design diameter can be effectively reduced, the scale of pump station construction can be lowered, and the goal of significantly reducing pipeline construction investment can be achieved.

2. Using drag reducers can improve transportation efficiency while maintaining existing pipeline equipment conditions. Especially in bottleneck areas, the use of drag reducers has a very significant effect, which can improve the transportation capacity of the entire pipeline and meet the requirements of multiple and fast transportation.

3. The use of drag reducers can reduce the demand for pumping stations during long-distance transportation. Not only can it reduce transportation energy consumption and operating costs, but it can also perform maintenance and renovation of pump units or pumping stations without stopping transportation, resulting in a decrease in maintenance and renovation costs.In addition, the use of drag reducers can reduce the number of pump station constructions in harsh environments and reduce the number of workers.

4. The use of drag reducers can reduce the working pressure of pipelines without affecting transportation efficiency, thereby improving the safety and reliability of pipeline operations. Due to years of operation, the eastern oil transportation website in China has suffered severe corrosion both inside and outside the pipeline, resulting in a significant decrease in its pressure resistance and posing a major threat to operational safety. By using drag reducers, the transportation pressure of the pipeline is greatly reduced, providing a guarantee for the safety of pipeline transportation.

The use of drag reducers as a short-term emergency measure has great advantages, so it has been widely applied in recent years. However, for pipelines that require long-term increase in transmission, the need for a large amount of drag reducing agents can lead to unclear economic benefits. Moreover, the addition of drag reducing agent injection devices in the oil transportation system can increase the overall system operation and failure rate, which is not conducive to daily operation management and maintenance.So, when it comes to drag reducing agent technology, priority should be given, but it cannot be blindly applied. Before application, it is necessary to carefully consider the overall situation. From a long-term perspective, the application of drag reducers in oil pipelines is the trend, and increasing research and exploration on the application technology of drag reducers is an inevitable choice for the development of China's pipeline industry.