Application and Exploration of Intelligent Technology for carbon dioxide transportation pipelines under the dual carbon background(Part 1)

Abstract

Carbon capture, utilization, and storage (CCUS) can effectively reduce industrial CO2 emissions on a large scale and is widely regarded as one of the essential key technologies for achieving global temperature control goals and China's carbon neutrality vision.The transportation of CO2 from the source to the utilization site is a key link in achieving the technological goals of CCUS industry.The development status of pipeline intelligent technology at home and abroad is summarized, with pipeline transportation as the main method; Introduced the phase classification of CO2 transportation pipelines and related issues, and analyzed the deep fusion mechanism between artificial neural network models and pipeline corrosion rate prediction based on the problems; Explained the positioning principles and applications of distributed optical fiber, characteristic spectrum, and robot inspection technology in pipeline leaks; Explored the development direction of CO2 transmission pipelines in intelligent construction.Although there is currently no widely unified understanding of the intelligent development of CO2 transmission pipelines, the future trend of intelligent development of CO2 transmission pipelines will be driven by the business needs of CO2 transmission pipelines, pipeline transmission technology+information and communication technology (ICT) as a means, and centered around the comprehensive perception, centralized sharing, prediction and warning, and collaborative operation of CO2 pipeline data. The research results can provide reference and guidance for the sustainable development of intelligent pipelines and the gradual promotion of smart pipelines in the future.

At present, reducing the global climate change process and achieving low-carbon has become the top priority for all countries. Among them, the method of separating, capturing, and storing CO2 from industrial production or coal/power plants, or injecting it into other production processes (CCUS), can be used to reduce CO2 emissions and is also the most efficient way to solve the greenhouse effect.Through literature review, the transportation methods of CO2 are mainly divided into pipeline transportation, automobile transportation, and ship transportation, and pipelines have high economic efficiency in transporting CO2.About 6000 km of CO2 pipelines have been built abroad, mainly in the United States, Canada, Türkiye, Norway, etc. The development of domestic CO2 pipelines is relatively slow.In 2023, the CO2 transportation pipeline of the CCUS demonstration project of Qilu Petrochemical Shengli Oilfield will be fully connected, and the CO2 transportation pipeline will gradually achieve large-scale application in China in the future. In recent years, with the iteration of information technology (such as cloud computing, big data technology, etc.) and its integration with business applications, intelligent manufacturing has gradually replaced industrial manufacturing and presented an accelerated development trend.As an important component of CCUS, CO2 transmission pipelines are actively exploring the development of intelligent pipelines and striving to create a smart CCUS.

1. Development status of intelligent pipeline technology at home and abroad

1.1 Current situation abroad

Foreign pipeline companies have their own characteristics in the intelligent construction of pipelines. Based on industrial Internet technology, digital technology, combined with geographic information system (GIS), work management system, national meteorological, exploration, agricultural and other external source data, Columbia Pipeline Group selects risk category scores, pipeline essential attributes, line patrol failures, real-time results of inspection, location attributes (such as characteristics of high consequence areas), and historical problem data (such as leakage) through pipeline management software platform, accurately locates and evaluates abnormal areas, and intelligently develops maintenance measures.

Italian company SNAM conducts research on monitoring, process operations, and digital twins of gas transmission grids based on intelligent technologies such as the Internet of Things (IoT), virtual reality (AR/VR), and machine learning (ML). It conducts real-time remote visual monitoring of natural gas pipelines and equipment (such as corrosion/leakage/damage), dynamic parameters (such as pressure/temperature) inspection and patrol, and uses various algorithms to achieve intelligent optimization of operation and maintenance paths.In addition, Enbridge Canada has applied digital twin technology to achieve pipeline visualization management, using 3D data and Hot Map technology to detect potential risks (such as defects, strains, etc.) in the surrounding areas of the pipeline, improving management efficiency and reducing maintenance costs.Phillips Corporation in the United States has achieved online pipeline inspection through intelligent detection robots; Rockwell, a British company, predicts the probability of pipeline equipment failure through machine algorithms, data management, big data analysis, and other tools.

1.2 Domestic Situation

In the 1980s, information technology was gradually introduced into China's oil and gas pipelines. In the late 1990s, Supervisory Control and Data Acquisition (SCADA) systems were widely used in the construction of oil and gas pipelines.In 2003-2004, China first proposed the concept of "digital pipeline" in the connection line of the West East Gas Pipeline between Hebei and Ningxia. It is mainly based on geographic information platforms and uses global positioning systems to digitally manage the entire lifecycle of pipeline construction and operation, providing data support for the construction of pipeline integrity management systems.In 2017, PetroChina achieved the construction of the China Russia East Gas Intelligent Pipeline through "digital transfer+intelligent operation+periodic management". In terms of digital transfer, a digital twin of the pipeline was built based on various digital design platforms and pipeline digital asset delivery, realizing automatic monitoring, intelligent diagnosis, and prediction of the natural gas pipeline system; In terms of intelligent operation, unmanned technology (such as one click start/stop station, intelligent distribution/inspection/security, etc.) and comprehensive perception technology (such as fiber optic warning, etc.) are adopted to improve the level and comprehensive benefits of pipeline and station safety operation management; In terms of cyclical management, the integrated control of the entire lifecycle of natural gas pipelines is achieved through intelligent construction sites during the construction period, intelligent internal inspection of pipelines before production, intelligent remote diagnosis of equipment after production, intelligent analysis and optimization of pipelines during operation, and expert database support.

Since 2014, Sinopec has focused on standard data and process business in the construction of intelligent pipelines, established a system standard framework related to intelligent pipelines, and developed related content on intelligent management functions such as integrity management and pipeline operation; Since 2007, China National Offshore Oil Corporation (CNOOC) has been carrying out digital pipeline construction and visual management starting from the liquefied natural gas pipeline network and receiving stations. With the help of geographic information systems and the integration of DCS/SCADA and other data, a fully informationized basic platform for pipeline production and operation system has been formed, becoming a unified CNOOC data warehouse.

2. CO2 pipeline transportation phase and problems faced

2.1 Phase classification of CO2 pipeline transportation

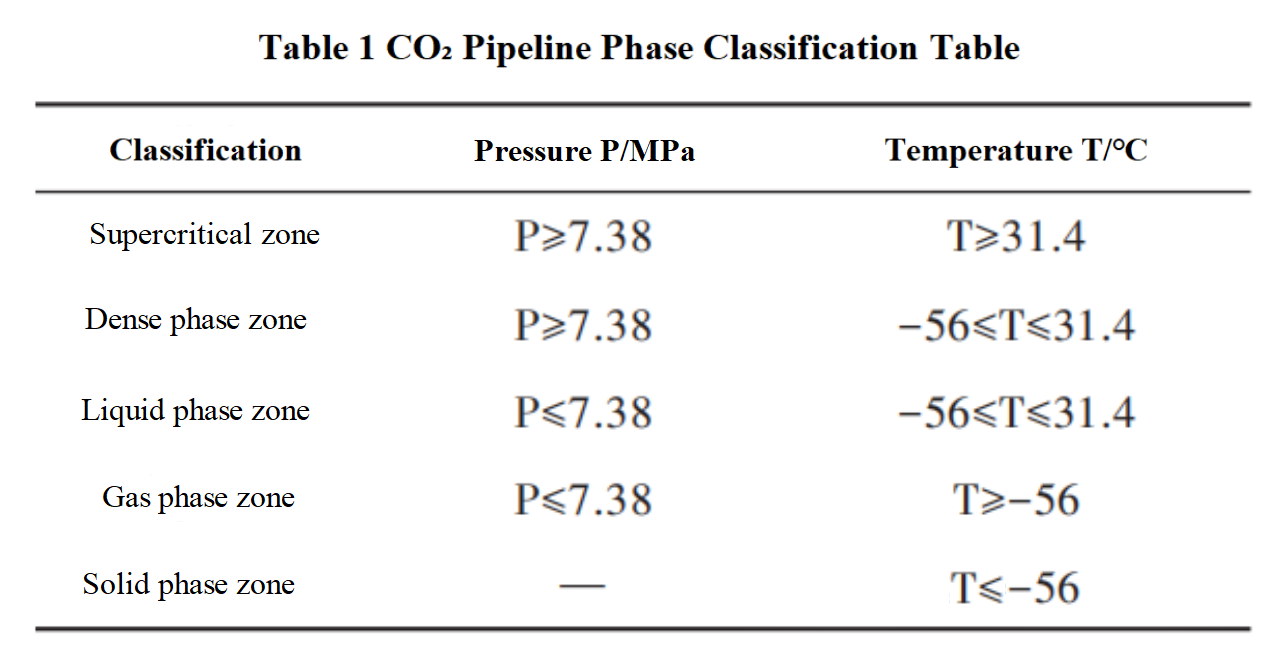

CO2 is gaseous at room temperature and pressure, with a density of 1.977 g/L (standard condition). According to different temperatures and pressures, CO2 pipeline transportation can be divided into five phase zones, as shown in Table 1.

Note:The critical point pressure is 7.38 MPa and the temperature is 31.4℃.

When CO2 is transported in the gas phase (P ≤ 7.38 MPa, T ≥ -56℃), the density is low, viscosity is low, and the transport volume is not large. The pipeline needs to be insulated to prevent liquefaction. This phase is mainly suitable for low transport volume and close range CO2 transportation; When CO2 is transported in liquid phase (P ≤ 7.38 MPa, -56 ≤ T ≤ 31.4℃), the density is high, viscosity is high, and the transportation volume is large. Before transportation, CO2 needs to be cooled (such as wellhead throttling refrigeration). This phase is mainly suitable for CO2 transportation in the gathering and transportation area at close distances; When CO2 is transported in supercritical conditions (P ≥ 7.38MPa, T ≥ 31.4℃), it has high density, low viscosity, and large transport volume. Therefore, high-power compressors and booster pumps are usually used to maintain long-distance transportation.

2.2 Problems faced by CO2 pipeline transportation

The phase characteristics of CO2 are complex and prone to changes in physical parameters, which can affect safe pipeline transportation. For example, the CO2 captured and separated from coal/flue gas contains free H2O, which interacts with each other to corrode pipelines and equipment. A product film will form on the inner wall of the pipeline, but the formation mechanism is still relatively unclear.Due to the influence of various impurities during the corrosion process, a large amount of sediment will appear. At present, a large amount of research and experiments are needed to establish a corrosion rate prediction model for this type of situation in order to obtain the final results.

CO2 pipeline leakage can also affect pipeline operation. Taking supercritical phase transport as an example, according to literature review, it is mainly divided into three processes: depressurization, jetting, and diffusion.However, due to various factors such as phase state and temperature field changes involved in the process of supercritical CO2 leakage, the reasons are complex, and there is no detailed information yet to explain the model architecture and calculation methods from jet to diffusion process. In addition, CO2 transmission pipelines may produce dry ice due to leaks or venting, which can also cause pipeline fractures.

3. Application of intelligent technology in CO2 transmission pipelines

3.1 Artificial Neural Network Technology

Due to the influence of various factors such as CO2 partial pressure, temperature, pH value, temperature, and water content of the corrosive medium, CO2 corrosion is a nonlinear and complex problem. Artificial neural networks (ANN) can be used to predict the CO2 corrosion rate and take corresponding anti-corrosion measures based on the degree of corrosion. Here are several commonly used artificial neural network techniques.

3.1.1 BP Neural Network (BPNN)

BPNN is a highly complex self-learning nonlinear dynamic system and one of the commonly used techniques in ANN. BPNN is an ANN that infinitely approximates any nonlinear function, based on the adaptive and self-learning characteristics of ANN. By repeatedly adjusting the threshold and weight, the calculation error is backpropagated to reduce the prediction result error. The calculation process consists of forward calculation and backward calculation.Usually, BPNN is combined with intelligent algorithms for CO2 corrosion rate prediction to solve problems such as low prediction accuracy, slow convergence speed, and susceptibility to local extremum points.

The genetic algorithm optimized BPNN model established by Wanli Equality was used to predict the corrosion rate under different temperature, CO2 partial pressure, and H2S partial pressure conditions.Adopting a three-layer network structure, the input layer consists of H2S partial pressure, CO2 partial pressure, and temperature, while the output layer represents corrosion rate.Using genetic algorithm (GA) to optimize the initial weights and thresholds of BPNN, with a mutation probability of 0.05, a population size of 10, a crossover probability of 0.6, and a maximum evolutionary generation of 15; The transfer function from the input layer to the hidden layer adopts the log sig function, the transfer function from the hidden layer to the output layer adopts the purelin function, and the network learning and training adopts the trainlm function. The network learning rate is 0.05, the target error is 0.005, the momentum coefficient value is 0.9, and the maximum training times are 500. After prediction, the average relative error is reduced from 10.0% to 8.6%.Liu Zhao et al. selected elevation difference, pipeline pressure, pipeline inclination angle, and pipeline holding Reynolds number as the main corrosion influencing factors. They used the BPNN model of niche genetic algorithm and standardized the original data using range transformation method. They established a 5×12×1 three-layer gas-liquid two-phase flow corrosion rate BPNN model and used genetic algorithm to obtain the optimal parameters. The program was developed for prediction, and the relative error after prediction was less than 2.0%.